Tesla singlehandedly jumpstarted the EV revolution, but despite this achievement, people still expect legacy carmakers to take over and wipe it out of the market. Evidence suggests this is no longer possible simply because Tesla has become like everyone else, too big to fail. Here's what makes Tesla such a great company.

Few believe today that Tesla can fail after scaling production past many other legacy carmakers. But back in the day, it was unthinkable for a new carmaker to emerge from the void and become successful. To achieve this while exclusively producing electric vehicles was a wild fantasy. That's why many expected it to fail, even when Tesla EVs were sold and appreciated throughout the world. Here's why this is not the case and what puts Tesla in a better position than many other carmakers.

The "Tesla killer" fantasy

Everyone agreed that Tesla opened the road to electrification, proving to others that it can be done. Yet, the common wisdom suggested that established carmakers have almost infinite resources to elevate electrification to new highs inaccessible to a startup like Tesla. Since 2012, when the Model S launched, I've seen many so-called "Tesla killers" failing to make a dent in Tesla's dominant position in the EV market.

Even mentioning "Tesla killer" today makes people laugh, especially as legacy carmakers have sworn, tried, and failed spectacularly to surpass Tesla. Sure, making cars is not trivial, and reaching the build quality level of German or Japanese luxury carmakers is still a distant dream for Tesla. But modern vehicles are much more than metal and oil, and key ingredients like software and features are Tesla's bread and butter.

Modern history has shown that mastering the drivetrain, body structure, and everything else that makes a car a car is no longer impossible for a new company. There are countless examples in the market, including Tesla and many Chinese carmakers. On the other hand, nailing the software part has proven nearly impossible for legacy carmakers. Look no further than Volkswagen, which broke its teeth trying to chew software, derailing entire vehicle programs for its many brands.

Software and technology are areas that change at a dizzying pace for legacy carmakers, who are used to things moving slowly. It took the car industry a decade to offer a decent infotainment system. Even today, most car owners prefer using their smartphones instead, which is why Android Auto and Apple CarPlay interfaces are so popular.

It's much more than software that makes Tesla a great company that it's nearly impossible to catch up with. Almost all traditional carmakers have electric vehicles in their lineups, and some are pretty decent. Still, none have managed to build them profitably, which might puzzle you. All, without exception, incur massive losses on their EV models.

A basic explanation is that nowadays, building cars is no longer enough to survive. You must tackle all aspects of the business, from mining to manufacturing to services and everything in between. Tesla understood that early and is now leading the way in many areas. Let's see what makes Tesla such a great company and why it's not just a car company, as others still see it.

Even though EVs are much simpler than ICE vehicles, they require different supply chains that need to be built from scratch. Battery packs, the most critical (and expensive) component of an electric car, need raw materials, factories, and suppliers that are already under stress. This is where Tesla is way ahead of everyone else, having already secured the most important resources available on the market. For newcomers, it's much more expensive to do the same, being so late in the game.

Tesla took over the Fremont NUMMI plant from Toyota as part of a supply deal for the electric powertrain of the electric RAV4 in 2010. This also involved Toyota taking a $50 million stake in Tesla, which it later sold before Tesla shares skyrocketed. The factory started building its first EV model, the Tesla Model S, in 2012. Previously, Tesla assembled the original Roadster in an old Chevrolet dealership in Menlo Park.

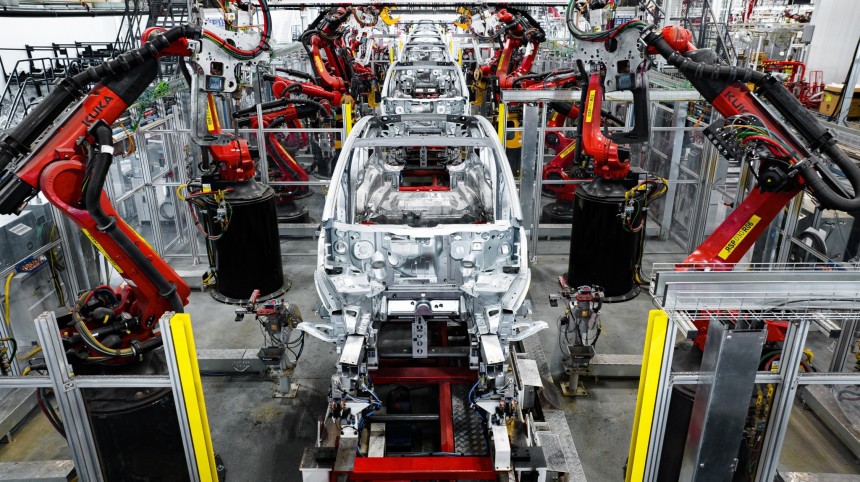

Giga Shanghai is the archetype of Tesla's new production facility, and it's truly revolutionary. Elon Musk, Tesla's CEO, calls it "the machine that builds the machine." Giga Berlin and Giga Texas are advanced copies of Giga Shanghai, which are yet to reach their full potential. They all build Tesla's second-generation vehicles, Model 3 and Model Y.

Tesla also optimized the vehicle structure to cut the production time even further, replacing hundreds of welded parts with single-piece megacastings. We've seen this with the Model Y, which also features a structural battery pack. Front and rear single-piece megacastings are currently only used in the Model Y assembled at Giga Texas, while Giga Shanghai and Giga Berlin vehicles only have a rear megacasting. Eventually, Tesla intends to use the new manufacturing technique in all its factories.

The first factory to employ the new manufacturing process will be the recently announced Giga Mexico, where the next-generation EVs will be built. For now, both the factory layout and the Gen-3 platform are developed at Giga Texas, which should speed things up a notch. When everything is deemed production-ready, the new concept will be transplanted to the new Mexican gigafactory. Other gigafactories, including the older ones, will adopt the novel manufacturing process over time.

Although Tesla's strategy appears to be very clear until now, there's a significant disruptor coming soon: the Cybertruck. The electric pickup truck doesn't fit into any of these patterns. It's not using the unboxed vehicle manufacturing process, and it needs its own production line and manufacturing technique. With an outer body made of stainless steel, it is much more complicated to build than any other vehicle model on the market.

As soon as it started production of the Model S in 2012, Tesla built its first charging stations in California, Nevada, and Arizona. As of September 2023, Tesla expanded its charging network to 5,500 stations with more than 50,000 connectors. It's the most extensive and successful fast-charging network on the planet and a significant asset for the company. A reliable charging network is a powerful incentive to buy Tesla EVs, although the EV maker recently opened its station to non-Tesla EVs.

The Supercharger network might bring the bulk of its Services revenue, but Tesla is also expanding its footprint in different directions. Service Centers will become more prominent as more Tesla EVs are bought and the vehicle fleet grows. Tesla is also expanding its insurance offering, with 12 US states covered at the end of September. The Services branch is increasingly important for Tesla, with more than $2 billion in revenues during the third quarter of 2023.

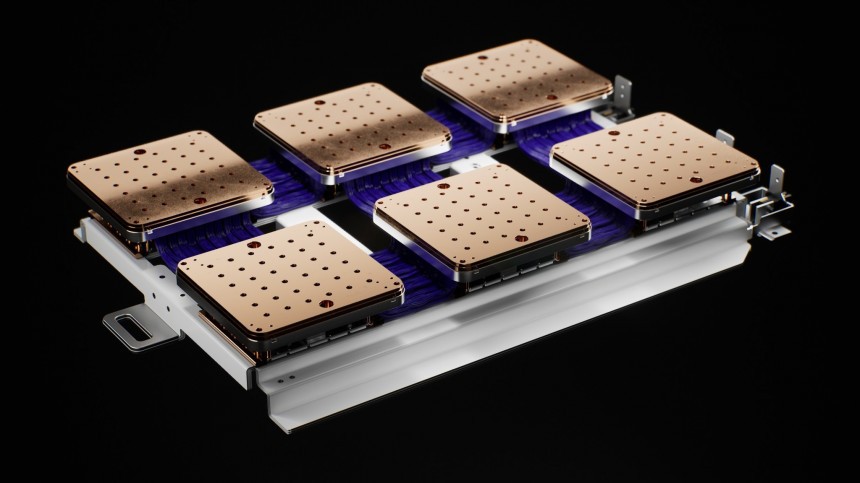

This allows charging an electric vehicle using energy harvested from the sun, powering the house, and stabilizing the grid in emergencies. Elon Musk's company also expanded into large battery storage systems with its Megapack business. These are industrial-scale storage systems intended to be used by utility companies for renewable energy supply smoothing, capacity support, frequency regulation, and voltage control.

Tesla is likely to expand its Energy operations and will probably want to spin off its Supercharger operations into a separate entity. Especially as its fast-charging network becomes more popular with non-Tesla owners, the Tesla Supercharger network is set to become one of its important profit centers.

The Megapack business is also growing at a fast pace as more countries around the world adopt renewables. Given the intermittent nature of solar and wind energy generation, Megapacks are needed to store the energy during peak generation time and release it during peak consumption time. This reduces the reliance on peaker power plants, which are among the most polluting and expensive to operate.

Elon Musk announced recently that FSD 12 will not count as beta software anymore and will be "end-to-end AI, from images in, to steering, brakes, and acceleration out." This will undoubtedly cement Tesla's position as an AI company, although its foray into artificial intelligence goes much further than self-driving cars.

Tesla is building its own supercomputers to train neural networks and developed proprietary silicon under the Dojo codename. The Dojo supercomputer works separately from Tesla's other supercomputer, built with Nvidia chips. Information about Tesla's Dojo is sometimes contradictory, with Elon Musk presenting it as a massive achievement and, at the same time, saying that he would've preferred to have more Nvidia chips.

Even though Dojo chips are not as good as Nvidia's, controlling the hardware and software can be a massive advantage in the long run. Tesla is severely compute-constrained, and it needs all the computing resources it can get to advance autonomous driving and other AI projects. These include the Tesla Bot, which seems like a departure from Tesla's mission.

The Tesla Bot uses similar capabilities to the Tesla FSD to move autonomously. This is why Elon Musk sees Tesla cars and Tesla bots as sister projects. Recent videos show that the Tesla bots have progressed tremendously in manipulating objects and moving around. The goal is to have a humanoid robot that could replace humans on the production lines and in the most boring or strenuous tasks.

In the long run, Elon Musk will likely externalize Tesla's AI operations to its newly-created xAI company. The artificial intelligence startup just announced its first chatbot named Grok, which it aims to offer first to X's Premium+ subscribers. The Grok name appears inspired by Robert A. Heinlein's science fiction novel Stranger in a Strange Land, although it later entered the dictionary as a verb meaning "to understand." It seems fitting.

The "Tesla killer" fantasy

Everyone agreed that Tesla opened the road to electrification, proving to others that it can be done. Yet, the common wisdom suggested that established carmakers have almost infinite resources to elevate electrification to new highs inaccessible to a startup like Tesla. Since 2012, when the Model S launched, I've seen many so-called "Tesla killers" failing to make a dent in Tesla's dominant position in the EV market.

Even mentioning "Tesla killer" today makes people laugh, especially as legacy carmakers have sworn, tried, and failed spectacularly to surpass Tesla. Sure, making cars is not trivial, and reaching the build quality level of German or Japanese luxury carmakers is still a distant dream for Tesla. But modern vehicles are much more than metal and oil, and key ingredients like software and features are Tesla's bread and butter.

Modern history has shown that mastering the drivetrain, body structure, and everything else that makes a car a car is no longer impossible for a new company. There are countless examples in the market, including Tesla and many Chinese carmakers. On the other hand, nailing the software part has proven nearly impossible for legacy carmakers. Look no further than Volkswagen, which broke its teeth trying to chew software, derailing entire vehicle programs for its many brands.

Tesla is much more than a car company

Software is important for a modern vehicle, and it's paramount for electric vehicles. You can build a legacy car with no piece of software whatsoever and still work, but mastering the inner workings of an electric vehicle, from charging to energy management to spinning the wheels, is impossible without software. This is where Tesla and other EV startups shine, and it's the one thing that's the most difficult to catch up.It's much more than software that makes Tesla a great company that it's nearly impossible to catch up with. Almost all traditional carmakers have electric vehicles in their lineups, and some are pretty decent. Still, none have managed to build them profitably, which might puzzle you. All, without exception, incur massive losses on their EV models.

A basic explanation is that nowadays, building cars is no longer enough to survive. You must tackle all aspects of the business, from mining to manufacturing to services and everything in between. Tesla understood that early and is now leading the way in many areas. Let's see what makes Tesla such a great company and why it's not just a car company, as others still see it.

Building cars is still the same, but different

Tesla's operations span industries, but its primary line of business is still building cars. Nevertheless, the way it makes cars is unique, from design to manufacturing to sales. Tesla still relies on suppliers to do the heavy lifting, but the vertical integration is unprecedented. The EV maker has a tight grip on the supply, production, and sales channels, controlling every aspect of its business. This is something that other carmakers are only now starting to realize.Even though EVs are much simpler than ICE vehicles, they require different supply chains that need to be built from scratch. Battery packs, the most critical (and expensive) component of an electric car, need raw materials, factories, and suppliers that are already under stress. This is where Tesla is way ahead of everyone else, having already secured the most important resources available on the market. For newcomers, it's much more expensive to do the same, being so late in the game.

Tesla took over the Fremont NUMMI plant from Toyota as part of a supply deal for the electric powertrain of the electric RAV4 in 2010. This also involved Toyota taking a $50 million stake in Tesla, which it later sold before Tesla shares skyrocketed. The factory started building its first EV model, the Tesla Model S, in 2012. Previously, Tesla assembled the original Roadster in an old Chevrolet dealership in Menlo Park.

The machine that builds the machine

Although Tesla still builds all current models in Fremont, its newer factories are designed very differently. The EV startup reinvented car manufacturing to optimize production times and costs. Tesla scrapped warehouses, and the parts needed in production are offloaded directly on the production line at precise moments and places. This is just one example of how Tesla improved its manufacturing processes.Tesla also optimized the vehicle structure to cut the production time even further, replacing hundreds of welded parts with single-piece megacastings. We've seen this with the Model Y, which also features a structural battery pack. Front and rear single-piece megacastings are currently only used in the Model Y assembled at Giga Texas, while Giga Shanghai and Giga Berlin vehicles only have a rear megacasting. Eventually, Tesla intends to use the new manufacturing technique in all its factories.

More disruption ahead

Tesla is also working on its Gen-3 platform, which will use a different manufacturing process and factory layout. Tesla called it an "unboxed vehicle" process because it splits the car into several sections that can be assembled simultaneously by different teams. This further speeds up the production time and cuts the factory footprint significantly. The unboxed vehicle process takes the single-piece megacasting concept and elevates it to a new level.The first factory to employ the new manufacturing process will be the recently announced Giga Mexico, where the next-generation EVs will be built. For now, both the factory layout and the Gen-3 platform are developed at Giga Texas, which should speed things up a notch. When everything is deemed production-ready, the new concept will be transplanted to the new Mexican gigafactory. Other gigafactories, including the older ones, will adopt the novel manufacturing process over time.

Although Tesla's strategy appears to be very clear until now, there's a significant disruptor coming soon: the Cybertruck. The electric pickup truck doesn't fit into any of these patterns. It's not using the unboxed vehicle manufacturing process, and it needs its own production line and manufacturing technique. With an outer body made of stainless steel, it is much more complicated to build than any other vehicle model on the market.

Tesla Services: an often overlooked revenue stream

Although the Tesla Supercharger network could be seen as a good fit for its energy business, Tesla still counts charging in the Services division. This is explained by the fact that Tesla mainly resells the electricity it buys from other companies. Although there are Supercharger stations integrated with solar panels and Megapack storage (Quartzsite, Arizona, is an example), most Superchargers use electricity from the grid.The Supercharger network might bring the bulk of its Services revenue, but Tesla is also expanding its footprint in different directions. Service Centers will become more prominent as more Tesla EVs are bought and the vehicle fleet grows. Tesla is also expanding its insurance offering, with 12 US states covered at the end of September. The Services branch is increasingly important for Tesla, with more than $2 billion in revenues during the third quarter of 2023.

Energy generation and storage

Following the release of the Master Plan Part Deux in 2016, Tesla started working on expanding its footprint in energy storage and integrating energy generation (Solar City) and storage (Tesla Powerwall). It was the moment Tesla Energy was founded, expanding operations with a new line of business. Tesla has now integrated power generation using solar panels or the Solar Roof with battery storage (Powerwall) and microgrid capabilities (Virtual Power Plant).This allows charging an electric vehicle using energy harvested from the sun, powering the house, and stabilizing the grid in emergencies. Elon Musk's company also expanded into large battery storage systems with its Megapack business. These are industrial-scale storage systems intended to be used by utility companies for renewable energy supply smoothing, capacity support, frequency regulation, and voltage control.

Tesla is likely to expand its Energy operations and will probably want to spin off its Supercharger operations into a separate entity. Especially as its fast-charging network becomes more popular with non-Tesla owners, the Tesla Supercharger network is set to become one of its important profit centers.

Is Tesla an Artificial Intelligence company?

It sure seems like that if you count its Full Self-Driving software as a result of artificial intelligence. Tesla uses neural networks for its autonomous driving features. These include FSD Beta for city driving and Autopilot for highway driving. With the recent FSD Beta builds, Tesla adopted a unified stack, which means that the same software stack controls highway driving and city driving.Elon Musk announced recently that FSD 12 will not count as beta software anymore and will be "end-to-end AI, from images in, to steering, brakes, and acceleration out." This will undoubtedly cement Tesla's position as an AI company, although its foray into artificial intelligence goes much further than self-driving cars.

Tesla is building its own supercomputers to train neural networks and developed proprietary silicon under the Dojo codename. The Dojo supercomputer works separately from Tesla's other supercomputer, built with Nvidia chips. Information about Tesla's Dojo is sometimes contradictory, with Elon Musk presenting it as a massive achievement and, at the same time, saying that he would've preferred to have more Nvidia chips.

Even though Dojo chips are not as good as Nvidia's, controlling the hardware and software can be a massive advantage in the long run. Tesla is severely compute-constrained, and it needs all the computing resources it can get to advance autonomous driving and other AI projects. These include the Tesla Bot, which seems like a departure from Tesla's mission.

In the long run, Elon Musk will likely externalize Tesla's AI operations to its newly-created xAI company. The artificial intelligence startup just announced its first chatbot named Grok, which it aims to offer first to X's Premium+ subscribers. The Grok name appears inspired by Robert A. Heinlein's science fiction novel Stranger in a Strange Land, although it later entered the dictionary as a verb meaning "to understand." It seems fitting.