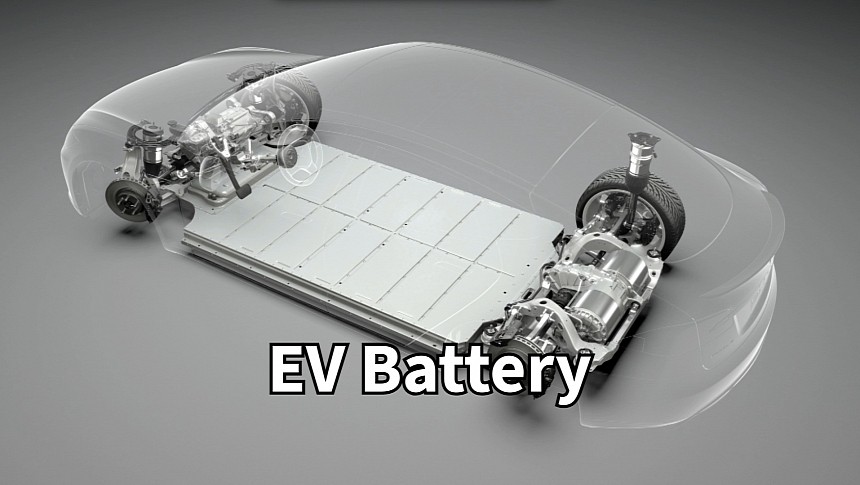

Although electric cars are almost as old as the automobile itself, they didn't become a worthy alternative to ICE vehicles until Li-ion batteries changed everything. These energy storage devices help power everything around us, from watches to electric cars and even cities. Let's see how EV battery evolved and where it's leading us.

Electric vehicles are now promoted as humankind's best tool to curb global warming and reduce pollution inside cities. Not everyone is convinced they are the best solution, but electric vehicles have advantages over their ICE counterparts. These start with lower operating costs and are boosted by the fact that EVs can turn about 90% of the energy consumed to charge them into mechanical work. If this sounds unrealistic, remember that EVs can recoup during braking an important part (more than 20%) of the used energy and feed it back into the battery.

Electric vehicles are disadvantaged in certain areas, with the most talked about being limited range, long recharging times, and high prices. If you group them like that, you'll notice that the advantages stem from using electricity, while the disadvantages are all generated by their Li-ion batteries. Once you realize that, it's a no-brainer that the auto industry should channel its efforts into improving the batteries that power electric vehicles to make everyone happy.

Carmakers started seriously considering electric vehicles during the petrol crisis in the 1970s. Back then, lead-acid batteries were the only solution, although Volkswagen experimented with sodium-sulfur batteries in the 1980s. Lead-acid batteries have many disadvantages, with weight and the short lifespan being the most important. Lead-acid batteries powered the original version of the GM EV1, although GM moved to nickel-metal hydride (NiMH) batteries with the second generation.

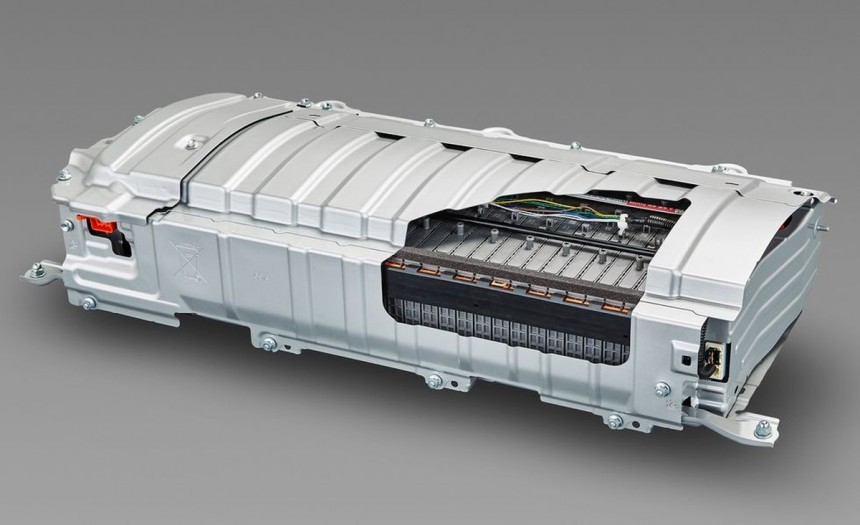

NiMH batteries were lighter and more energy-dense than lead-acid batteries and could have exceptionally long lifecycles when appropriately used. Many hybrid cars, including the Toyota Prius, used NiMH batteries, although most have moved to lithium-ion batteries recently. These batteries are much lighter and hold more energy, although early Li-ion cells were sensitive to temperature changes and degraded quickly. The latter has earned them a bad reputation that has stuck until today despite not being valid anymore.

The high gas prices or the perspective of not having access to petrol has always been the catalyst for alternative powertrains. This is why the 2009 financial crisis offered another boost to EV development. By then, Elon Musk and Tesla were already promising to save the planet with the famous Master Plan published in 2006. Tesla was also the first car company to use Li-ion batteries, with the Roadster starting deliveries in 2008. Mitsubishi introduced the i-MiEV one year later, and Nissan launched the Leaf in 2010. The history was being written.

The first commercialized chemistry was lithium-cobalt oxide (LCO), with a high specific energy but low specific power. This makes them suitable for low-power devices, such as portable electronics. They have a short lifespan and, therefore, are being replaced by other types. Lithium-manganese-oxide types improve on this chemistry with benefits in terms of power, thermal stability, and safety. Their main drawback is the short lifespan of about 300-700 charge cycles.

Lithium-nickel-manganese-cobalt-oxide (NMC) batteries have high specific energy and are very stable, which makes them ideal for powering electric vehicles and other personal mobility devices. Lithium-nickel-cobalt-aluminum-oxide batteries offer the highest specific energy and have a longer lifecycle, but they are less stable than the NMC cells. Tesla uses them in its electric vehicles, although the EV maker has also explored using NMC cells and, more recently, iron-based batteries.

Lithium-iron-phosphate (LFP or LiFePO4) batteries are still new to the EV industry but hold many promises. Although they have lower specific energy than NMC/NCA, they are much cheaper to produce because they don't use expensive and rare materials. They have very long lifecycles and excellent thermal stability. Because of the lower energy density, they are used mainly in cheaper and less performant EVs. The chemistry is improving, though, and newer LFP chemistries have shown energy density almost on par with NCM cells.

Another Li-ion battery type, lithium-titanate (LTO), uses this material instead of the usual graphite anode. The cathode can use other chemistry, including NMC or LTO. The result is a very safe battery with a long lifespan that charges faster than any other type of battery. This may sound like the holy grail of Li-ion batteries, but it's not. LTO batteries are costly to produce and have low energy density. They are mainly used in military and space applications because of that.

Speaking of electrolytes, most Li-ion batteries used in electric vehicles today (and not only) use either a liquid or semisolid (gel) polymer electrolyte. The latter can be found in lithium polymer (LiPo) batteries, with the added advantage of a higher specific energy. Although few EV models use LiPo batteries, the benefits might favor them in the future.

If you're wondering what's wrong with liquid electrolytes used in most Li-ion batteries nowadays, well, they're highly flammable. A faulty battery or a thermal, electrical, or mechanical abuse can lead to overheating, turning Li-ion batteries into incendiary bombs that are very hard to extinguish. EV battery fires are rare but not unheard of, as owners of the Chevrolet Bolt know too well.

Of course, non-flammable liquid electrolytes are ideal, but they are unavailable. Instead, researchers try to advance solid electrolytes, which promise to be non-flammable and allow higher energy density and longer lifecycles. Many research labs and companies are trying to offer a commercially-viable solid-state battery, but they still haven't discovered the ideal solid electrolyte.

Tesla was the first to launch a production model with cylindrical Li-ion battery cells, but other carmakers that followed chose other form factors. Cylindrical cells have the advantage of being durable, but they are more expensive to produce. Their durability is enhanced by the fact that thermal management is more efficient in the case of cylindrical cells.

The downside is that packing many of them inside a battery pack leaves a lot of wasted space. It's also unpractical to have many cylindrical cells, although Tesla also uses them for the Semi's huge battery packs. To mitigate this issue, Tesla increased the diameter of the cells from 18 mm of the 18650 cells to 21 mm in the 21700 cells and recently to 46 mm with the 4680 cells. This trend was followed by other carmakers, including some favoring prismatic cells, such as BMW.

Prismatic cells can use the space inside the battery pack more efficiently, so energy density is higher. On the other hand, cooling the cells is more problematic, affecting the lifespan and sometimes leading to thermal runaway. Many traditional carmakers have used prismatic cells, including Volkswagen, Mercedes-Benz, and GM.

Prismatic cells have a bright future as LFP cells become more popular. Because LFP cells are more thermally stable, they can support higher temperatures inside the pack. They can also use the prismatic shape to pack more cells in a given space, thus increasing energy density. That's why most LFP cells used in the automotive industry are prismatic, although there are no limitations to what form factor they can be made into.

Finally, pouch batteries have the advantage that they can be packed more closely and thus offer increased energy density compared to other packaging types. Pouch cells enclose the battery elements in a thin, metallic bag, which makes them more flexible. The problem is that pouch batteries are prone to swelling during charging. Thermal management inside the pack is also tricky, and if thermal runaway occurs, there's nothing to spread heat from propagating to adjacent cells. GM and Hyundai used pouch-type cells and had terrible experiences with Chevy Bolt and Hyundai Kona battery fires.

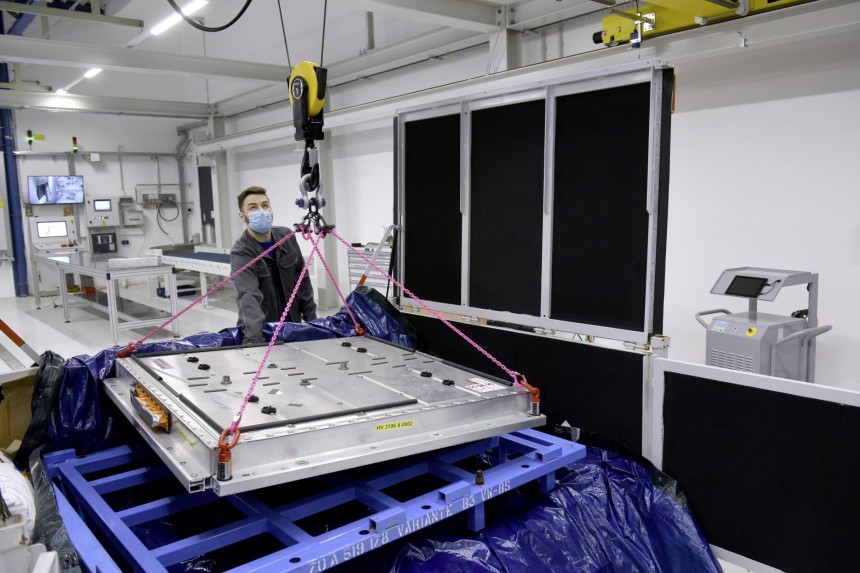

Besides the cell package, how you use these cells and how you build the final battery pack is also important. Traditionally, the battery pack was a large structure holding individual cells grouped into modules. This offered structural advantages but was inefficient, adding more weight to a vehicle. In recent years, carmakers have moved to more efficient packaging, like cell-to-pack (CTP), which eliminates modules and stores individual cells directly inside the battery. This improves energy density and allows the building of more compact battery packs.

Tesla also pioneered the concept of a structural battery pack. Instead of bolting the battery to the car structure, it made the battery pack a part of its structure. We saw this with the Model Y and, more recently, the Cybertruck. The battery packs of these models have structural roles, holding together the front and rear structures and other car parts, such as the seats. This further reduces the weight of the car, improving efficiency.

As I explained earlier, Li-ion cells come in various flavors, and the ones used in electric cars last much longer than phone batteries. Not only because they are better but because thermal management makes all the difference. If you wonder about this, remember how early Nissan Leaf batteries died prematurely because the Leaf lacked battery thermal management. Although the carmaker later corrected the issue, the EV battery's short lifespan remained in the collective memory.

Electric vehicles are still new, with the Tesla Model S barely a decade on the market, so it's difficult to assess the durability of EV batteries. The EV sales have increased exponentially, with most of the EVs on the roads being produced in the past three years. A fair analysis is further complicated because carmakers continuously improve their batteries. What was true for the 2012 Tesla Model S no longer stands for those produced last year.

The little data we have on hand shows that EV batteries can last many years, with even early models still in use today. That doesn't mean no electric vehicle needed a battery replacement, but statistically, these cases are rare. A recent study showed that only 1.5 percent of electric vehicles required a battery replacement outside of warranty or recalls. Sure, it's unpleasant when it happens, and the replacement costs are high, but the probability is low, and the odds are improving with every model year as Li-ion batteries get better.

Time is always a factor, as the chemicals inside battery cells lose their properties over time. Still, a battery degrades faster when it's depleted or fully charged. This means that time is not an important factor affecting battery life, but the state of charge is. Research shows that batteries degrade faster when they're below 20% and above 80%. This is why carmakers recommend charging the car's battery fully only when needed for a road trip. The sweet spot is between 50% and 60% state of charge, where the degradation is minimal.

Besides time and state of charge, high temperature takes the biggest toll on a battery's life. The higher the temperature, the faster the batteries degrade. This emphasizes the importance of a good thermal management system. It also explains why EVs that lacked such a system, like early Nissan Leaf EVs, were particularly bad in this regard.

Finally, fast charging can also affect battery cells, as high charge rates are not good for the battery. To make matters worse, fast charging works best with a warm battery. That's why the thermal management system pre-conditions (warms up) the battery when you set a fast charger as a destination in the navigation. Higher temperature always means more rapid degradation and shorter lifespan. Still, some EV owners have reported insignificant degradation even after years of using fast chargers exclusively.

While ICE cars pollute the more they are driven, electric vehicles become cleaner the more they travel. At the end of their lifecycle, both combustion and electric vehicles need to be scrapped, but in the case of EVs, the most polluting part, its battery pack, can be recycled. That's right, they can, and anyone claiming otherwise is only helping spread more FUD about electric vehicles.

Most materials used to produce Li-ion batteries can be recycled, and the recycling rate is pretty high. Industry veterans say recycled materials have higher purity than those processed from raw materials. If that's true, why are we not already seeing more battery recycling plants? The only reason is that electric vehicles are still new, and there aren't many battery packs that can be recycled at the moment.

The Li-ion battery recycling industry is only emerging, and new recycling methods are being researched and tested. However, this industry will not be efficient until enough battery packs reach their end of life. Still, battery recycling startups are flourishing, the most advanced being Redwood Materials. The company, founded by the ex-Tesla executive JB Straubel, is building a large recycling facility in Nevada, and carmakers are already lining up as customers.

Silicon anodes are among the most promising changes to Li-ion batteries, which should vastly improve energy density. The process is not yet optimized, so they are still not produced at scale. Another promising advancement is the use of dry electrode coating pioneered by Tesla. This aims to cut production costs significantly by eliminating a time- and energy-consuming step in Li-ion battery manufacturing.

Li-ion battery performance could benefit the most from using solid electrolytes. Many companies try to advance solid-state batteries, although the technology is not yet mature to enter production. Among the issues that need to be solved are higher costs, a high rate of mechanical failure, and the formation of dendrites, which penetrate the electrolyte and cause electrical short circuits.

Even though Li-ion batteries seem like the best solution now, new chemistries are developing. By replacing Lithium with other metals, batteries can hold more energy, endure more charging-discharging cycles, or become cheaper. Among the most promising are sodium-ion and sodium-sulfur batteries, as well as calcium-based batteries. They're all in a lab phase for now, but the future of energy storage becomes brighter the more we need better batteries. Ultimately, electric vehicles will prevail not because they are forced upon us by climate change but because they are better and much more efficient.

Electric vehicles are disadvantaged in certain areas, with the most talked about being limited range, long recharging times, and high prices. If you group them like that, you'll notice that the advantages stem from using electricity, while the disadvantages are all generated by their Li-ion batteries. Once you realize that, it's a no-brainer that the auto industry should channel its efforts into improving the batteries that power electric vehicles to make everyone happy.

A little EV battery history

Even though modern EV batteries are all Li-ion batteries, this wasn't always the case. Li-ion batteries are still new, with the first commercial batteries using this technology appearing in the 1990s. The first electric cars used the dominant battery technology at their time, which was the lead-acid battery. This is still used today to help most cars start the engine and power ancillary electronics when the engine is not running. But they're on their way out, as Li-ion batteries have begun to make inroads in this field.Carmakers started seriously considering electric vehicles during the petrol crisis in the 1970s. Back then, lead-acid batteries were the only solution, although Volkswagen experimented with sodium-sulfur batteries in the 1980s. Lead-acid batteries have many disadvantages, with weight and the short lifespan being the most important. Lead-acid batteries powered the original version of the GM EV1, although GM moved to nickel-metal hydride (NiMH) batteries with the second generation.

The high gas prices or the perspective of not having access to petrol has always been the catalyst for alternative powertrains. This is why the 2009 financial crisis offered another boost to EV development. By then, Elon Musk and Tesla were already promising to save the planet with the famous Master Plan published in 2006. Tesla was also the first car company to use Li-ion batteries, with the Roadster starting deliveries in 2008. Mitsubishi introduced the i-MiEV one year later, and Nissan launched the Leaf in 2010. The history was being written.

What are the Li-ion battery types in use today?

Although we keep talking about Li-ion batteries as a whole, there are many types with different chemistries and characteristics. None of them is perfect, and their benefits and drawbacks dictate the best application for each of them. The main differentiator is their chemistry, which explains why they are named after the active materials used to build them. There are six main types of Li-ion batteries, although not all are suitable for use in electric vehicles.The first commercialized chemistry was lithium-cobalt oxide (LCO), with a high specific energy but low specific power. This makes them suitable for low-power devices, such as portable electronics. They have a short lifespan and, therefore, are being replaced by other types. Lithium-manganese-oxide types improve on this chemistry with benefits in terms of power, thermal stability, and safety. Their main drawback is the short lifespan of about 300-700 charge cycles.

Lithium-nickel-manganese-cobalt-oxide (NMC) batteries have high specific energy and are very stable, which makes them ideal for powering electric vehicles and other personal mobility devices. Lithium-nickel-cobalt-aluminum-oxide batteries offer the highest specific energy and have a longer lifecycle, but they are less stable than the NMC cells. Tesla uses them in its electric vehicles, although the EV maker has also explored using NMC cells and, more recently, iron-based batteries.

Another Li-ion battery type, lithium-titanate (LTO), uses this material instead of the usual graphite anode. The cathode can use other chemistry, including NMC or LTO. The result is a very safe battery with a long lifespan that charges faster than any other type of battery. This may sound like the holy grail of Li-ion batteries, but it's not. LTO batteries are costly to produce and have low energy density. They are mainly used in military and space applications because of that.

Chemistry isn't everything: playing with electrolytes

Li-ion batteries are a vast domain, and researchers try many different paths to find the best energy storage solution. Playing with the cathode and anode materials can be rewarding, but a battery has more variables. The most critical is the electrolyte itself, although other components of a Li-ion battery and even the packaging play essential roles. It's incredible how the tiniest modification in the battery structure can yield very different results.Speaking of electrolytes, most Li-ion batteries used in electric vehicles today (and not only) use either a liquid or semisolid (gel) polymer electrolyte. The latter can be found in lithium polymer (LiPo) batteries, with the added advantage of a higher specific energy. Although few EV models use LiPo batteries, the benefits might favor them in the future.

Of course, non-flammable liquid electrolytes are ideal, but they are unavailable. Instead, researchers try to advance solid electrolytes, which promise to be non-flammable and allow higher energy density and longer lifecycles. Many research labs and companies are trying to offer a commercially-viable solid-state battery, but they still haven't discovered the ideal solid electrolyte.

But what about the packaging?

Li-ion battery cells come in different form factors, and those used in the automotive industry are no different. There are three main packaging types: cylindrical, prismatic, and pouch, each with its own benefits and disadvantages. There are heated debates about which form factor works best for electric vehicles, but the truth is that carmakers use different cell packaging for various reasons.Tesla was the first to launch a production model with cylindrical Li-ion battery cells, but other carmakers that followed chose other form factors. Cylindrical cells have the advantage of being durable, but they are more expensive to produce. Their durability is enhanced by the fact that thermal management is more efficient in the case of cylindrical cells.

The downside is that packing many of them inside a battery pack leaves a lot of wasted space. It's also unpractical to have many cylindrical cells, although Tesla also uses them for the Semi's huge battery packs. To mitigate this issue, Tesla increased the diameter of the cells from 18 mm of the 18650 cells to 21 mm in the 21700 cells and recently to 46 mm with the 4680 cells. This trend was followed by other carmakers, including some favoring prismatic cells, such as BMW.

Prismatic cells have a bright future as LFP cells become more popular. Because LFP cells are more thermally stable, they can support higher temperatures inside the pack. They can also use the prismatic shape to pack more cells in a given space, thus increasing energy density. That's why most LFP cells used in the automotive industry are prismatic, although there are no limitations to what form factor they can be made into.

Finally, pouch batteries have the advantage that they can be packed more closely and thus offer increased energy density compared to other packaging types. Pouch cells enclose the battery elements in a thin, metallic bag, which makes them more flexible. The problem is that pouch batteries are prone to swelling during charging. Thermal management inside the pack is also tricky, and if thermal runaway occurs, there's nothing to spread heat from propagating to adjacent cells. GM and Hyundai used pouch-type cells and had terrible experiences with Chevy Bolt and Hyundai Kona battery fires.

Besides the cell package, how you use these cells and how you build the final battery pack is also important. Traditionally, the battery pack was a large structure holding individual cells grouped into modules. This offered structural advantages but was inefficient, adding more weight to a vehicle. In recent years, carmakers have moved to more efficient packaging, like cell-to-pack (CTP), which eliminates modules and stores individual cells directly inside the battery. This improves energy density and allows the building of more compact battery packs.

How long can EV batteries last before they need replacement?

Many people talk about Li-ion batteries as a group and consider that EV batteries are no better than phone or laptop batteries. The fact that carmakers don't make the difference is not helping either. This is why many people think EV batteries degrade quickly, making EVs less valuable on the used market. After all, who would buy a car with a dead battery that costs more than the entire vehicle to replace?As I explained earlier, Li-ion cells come in various flavors, and the ones used in electric cars last much longer than phone batteries. Not only because they are better but because thermal management makes all the difference. If you wonder about this, remember how early Nissan Leaf batteries died prematurely because the Leaf lacked battery thermal management. Although the carmaker later corrected the issue, the EV battery's short lifespan remained in the collective memory.

Electric vehicles are still new, with the Tesla Model S barely a decade on the market, so it's difficult to assess the durability of EV batteries. The EV sales have increased exponentially, with most of the EVs on the roads being produced in the past three years. A fair analysis is further complicated because carmakers continuously improve their batteries. What was true for the 2012 Tesla Model S no longer stands for those produced last year.

What kills Li-ion batteries, and what can be done to extend their life?

Although Li-ion batteries can last for a long time, this doesn't mean they are everlasting. Cells always degrade, whether they are charged, discharged, or sitting on a shelf. The question is how fast they lose capacity and what can we do to prolong their lifespan. Many known factors accelerate Li-ion cell degradation and make batteries lose capacity. This is important, as a battery is considered "worn out" when it retains 70% of the original capacity.Time is always a factor, as the chemicals inside battery cells lose their properties over time. Still, a battery degrades faster when it's depleted or fully charged. This means that time is not an important factor affecting battery life, but the state of charge is. Research shows that batteries degrade faster when they're below 20% and above 80%. This is why carmakers recommend charging the car's battery fully only when needed for a road trip. The sweet spot is between 50% and 60% state of charge, where the degradation is minimal.

Besides time and state of charge, high temperature takes the biggest toll on a battery's life. The higher the temperature, the faster the batteries degrade. This emphasizes the importance of a good thermal management system. It also explains why EVs that lacked such a system, like early Nissan Leaf EVs, were particularly bad in this regard.

Can Li-ion batteries in electric vehicles be recycled?

This is another urban legend that fuels FUD about electric vehicles. According to this legend, EV batteries need many resources to dig out raw minerals and turn them into battery packs, generating more pollution than an electric vehicle can offset during its entire lifetime. This is only partly true, and only if we consider that both EVs and ICE cars sit in a garage. The truth is that cars are made to be driven, and people drive them a lot, and that's where things change.While ICE cars pollute the more they are driven, electric vehicles become cleaner the more they travel. At the end of their lifecycle, both combustion and electric vehicles need to be scrapped, but in the case of EVs, the most polluting part, its battery pack, can be recycled. That's right, they can, and anyone claiming otherwise is only helping spread more FUD about electric vehicles.

Most materials used to produce Li-ion batteries can be recycled, and the recycling rate is pretty high. Industry veterans say recycled materials have higher purity than those processed from raw materials. If that's true, why are we not already seeing more battery recycling plants? The only reason is that electric vehicles are still new, and there aren't many battery packs that can be recycled at the moment.

What's coming next for EV batteries?

Like every piece of technology, Li-ion batteries have appeared, rose to fame, and will eventually be replaced by something better. At this moment, many scientists and researchers are working tirelessly to improve Li-ion cells. It's safe to assume Li-ion batteries are still far from their peak potential, even though the development seems slow. Let's not forget that they only entered the market in the 1990s, so they're still relatively new.Silicon anodes are among the most promising changes to Li-ion batteries, which should vastly improve energy density. The process is not yet optimized, so they are still not produced at scale. Another promising advancement is the use of dry electrode coating pioneered by Tesla. This aims to cut production costs significantly by eliminating a time- and energy-consuming step in Li-ion battery manufacturing.

Even though Li-ion batteries seem like the best solution now, new chemistries are developing. By replacing Lithium with other metals, batteries can hold more energy, endure more charging-discharging cycles, or become cheaper. Among the most promising are sodium-ion and sodium-sulfur batteries, as well as calcium-based batteries. They're all in a lab phase for now, but the future of energy storage becomes brighter the more we need better batteries. Ultimately, electric vehicles will prevail not because they are forced upon us by climate change but because they are better and much more efficient.