Skoda uses artificial intelligence to identify maintenance problems on the assembly line. At its main plant in Mlada Boleslav in the Czech Republic, Skoda FabLab has installed a system called "Magic Eye" that continuously monitors assembly line equipment for optimal operation.

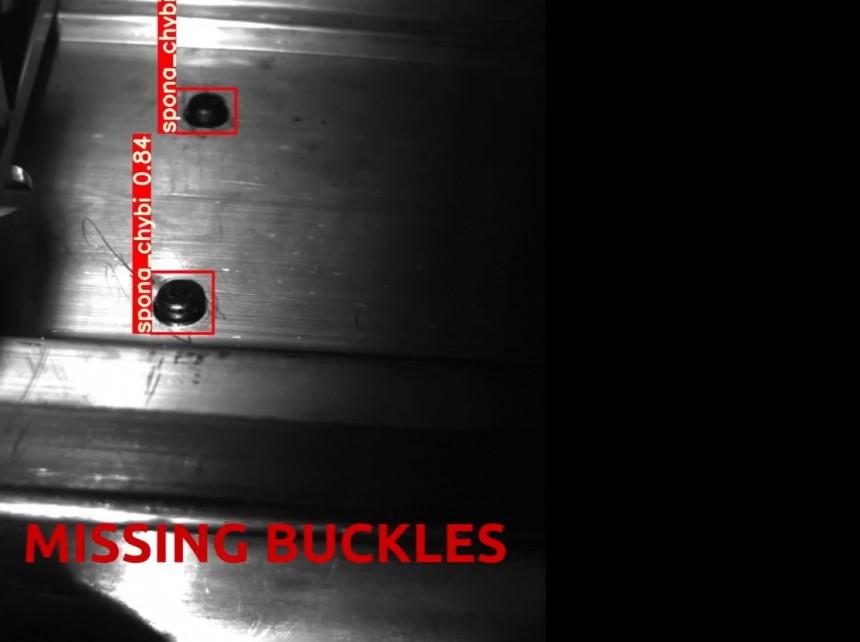

Skoda uses "Magic Eye" on the assembly line for the Enyaq iV and Octavia models at its main plant. It is based on a computer using Artificial Intelligence. Irregularities are thus detected very quickly and the computer sends notifications to the maintenance team for correction. Although not new worldwide, Skoda is one of the first companies in the Czech Republic to make use of AI-supported predictive maintenance capabilities.

"Magic Eye" compares its high-precision photographs to thousands of previously stored images in real time. This enables it to detect deviations from the optimal baseline conditions and identify error sources. The use of blue light ensures that the AI tool distinguishes between cracks and scratches and makes accurate diagnoses. Furthermore, the system's knowledge base is constantly being expanded. If it discovers a worn bolt, for example, it marks the location as error-free once the part is replaced and checked again. The system uses information from previous irregularities to evaluate detected deviations.

The FabLab simulated a section of the assembly line to enable further system optimization and accelerate wider integration at Skoda sites. This "implementation arena" can be used to test different camera settings, configure system parameters, and simulate assembly line damage.

In Europe, the way was paved as early as last year when BMW used artificial intelligence (AI) across its global operations. The German company has developed software that makes it easy to create AI applications for object recognition. The centerpiece of the software is the so-called BMW Labeling Tool Lite. This tool allows users to easily label objects in images, offline, to quickly create AI applications that can then reliably identify those objects in images during production.

However, at BMW, the foundations for new technologies using artificial intelligence have been laid as early as 2021. At that time, the German carmaker planned to start producing electric vehicle propulsion systems at its plant in Regensburg, Bavaria. At that plant, long before any new parts rolled off the production line, the entire manufacturing process was taking place in realistic detail inside a virtual version of the factory.

There is a high interest in using artificial intelligence to control robots and other industrial machines for the car industry. As in the case of an operation such as the identification of irregular objects, this technology has the potential to help automate much of the logistics activity.

This frequently employs an AI approach known as reinforcement learning, which involves an algorithm experimenting and learning how to achieve a specific goal based on positive feedback.

"Magic Eye" compares its high-precision photographs to thousands of previously stored images in real time. This enables it to detect deviations from the optimal baseline conditions and identify error sources. The use of blue light ensures that the AI tool distinguishes between cracks and scratches and makes accurate diagnoses. Furthermore, the system's knowledge base is constantly being expanded. If it discovers a worn bolt, for example, it marks the location as error-free once the part is replaced and checked again. The system uses information from previous irregularities to evaluate detected deviations.

The FabLab simulated a section of the assembly line to enable further system optimization and accelerate wider integration at Skoda sites. This "implementation arena" can be used to test different camera settings, configure system parameters, and simulate assembly line damage.

However, at BMW, the foundations for new technologies using artificial intelligence have been laid as early as 2021. At that time, the German carmaker planned to start producing electric vehicle propulsion systems at its plant in Regensburg, Bavaria. At that plant, long before any new parts rolled off the production line, the entire manufacturing process was taking place in realistic detail inside a virtual version of the factory.

There is a high interest in using artificial intelligence to control robots and other industrial machines for the car industry. As in the case of an operation such as the identification of irregular objects, this technology has the potential to help automate much of the logistics activity.

This frequently employs an AI approach known as reinforcement learning, which involves an algorithm experimenting and learning how to achieve a specific goal based on positive feedback.