We started the discussion in the previous part based on EVs’ main drawbacks for most car owners. It’s their short ranges and long charging times compared to internal combustion engine cars. Let’s take a look at the pro and cons of conductive charging. Is it feasible for electric vehicles?

But before that, let me give you a short reminder about the conclusions of the first part of this article. Swapping batteries is on the rise in China, and it seems to solve the “range anxiety” problems. The depleted battery in the car is changed with a fully charged one in a matter of minutes.

It’s as quick as filling up an ICE car’s tank, then you can travel several hundred miles until you get to another battery swap station. You don’t own the battery; you simply pay for using it in your car. It’s almost the same as paying for the gasoline you burn in your car’s engine.

However, for this technology to be embraced globally, it requires very stringent standardization, and this means limitations to the vehicle and battery design. Also, it’s much more costly than plug-in charging networks, and many fear a monopoly of just a few companies due to patent rights.

So, the industry searched for other solutions to make electric vehicles more user-friendly in terms of long ranges. One of them is conductive charging. You are very familiar with it because of trams and electric trains.

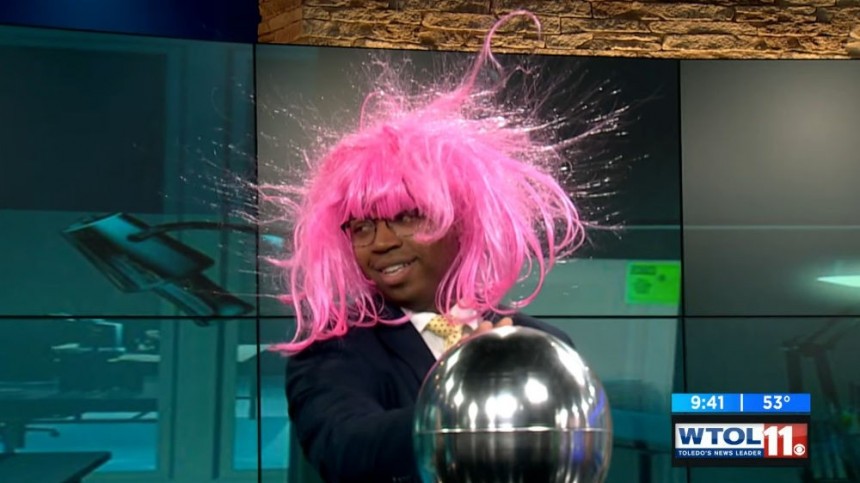

Your hair was suddenly electrified because you were experimenting with conductive charging. The metal ball was charged, and you were neutral. By touching it with your hands, you were receiving the electrons from the sphere. Depending on the charge, you could even turn on a light bulb in your hand.

So, conductive charging is a kind of wireless charging, but it requires direct contact between the two objects for the electrical current to pass from one to the other. You can say it’s also a plug-in charging type but without the plug.

It's not a scientifical explanation at all, but it’s easy to understand why trying to touch high-voltage power lines is absolutely stupid. The human body is simply not suited to receive a high amount of electricity. That’s why we hide from lightning in the storm.

The pantographs were mainly used in architecture until another German, Walter Reichel from Siemens & Haiske, used a pantograph as a current collector in 1889. His invention simply consisted of a pantograph mechanism to move up and down a graphite contact strip.

By keeping this strip in contact with the overhead wires, it collects the electrical current and transfers it to the electrical motor. The pantograph can be used either stationary or when the vehicle is moving. That’s why electric locomotives and trams don’t need batteries.

I admit, when I was a kid, the idea of cars fitted with pantographs on their roofs crossed my mind. The cities full of electrical metal nets between buildings were pretty hard to imagine, though. It was childish and naive. But it turns out I wasn’t the only one.

Trolleybuses are the best example of wheeled vehicles that don’t stay on fixed railways, like locomotives or trams. Instead of the pantograph, they use much simpler trolley poles as current collectors. The only problem is, once that pole is no longer in contact with the overhead wire, the electric motor stops working.

The electric motor needs electricity, but that’s an understatement. You can feed that electricity by collecting it from somewhere around the vehicle. Or you can feed the electricity stored in a battery. Or you can do both to avoid the previous scenario of no wire contact.

Someone did. But it’s not about cars, it’s about heavy-duty vehicles. In 2016, Scania and Siemens opened the world’s first eHighway in Sweden. It was a pilot project covering a two-kilometer (1.2 miles) stretch of the E16 highway north of Stockholm.

Authorities and companies mounted on that stretch an overhead catenary wire system on special poles. The vehicles used for the trial were two diesel-hybrid trucks, fitted with pantographs on the driver cabin’s roof. Simply put, rail electrification was transferred to road transport.

At that time, a sensor system enabled the pantograph to connect to and disconnect from the overhead line at speeds of up to 90 km per hour (56 miles per hour). While using electricity from the wires, the diesel engine wasn’t working, thus emissions were down to zero.

Since then, several other trials started throughout Europe. In Germany, recent trials feature electric heavy-duty trucks. When a truck is using the pantograph to feed electricity to the electric motor, its battery is recharged by moving wheels. This way, the truck has enough range when not using the overhead power lines.

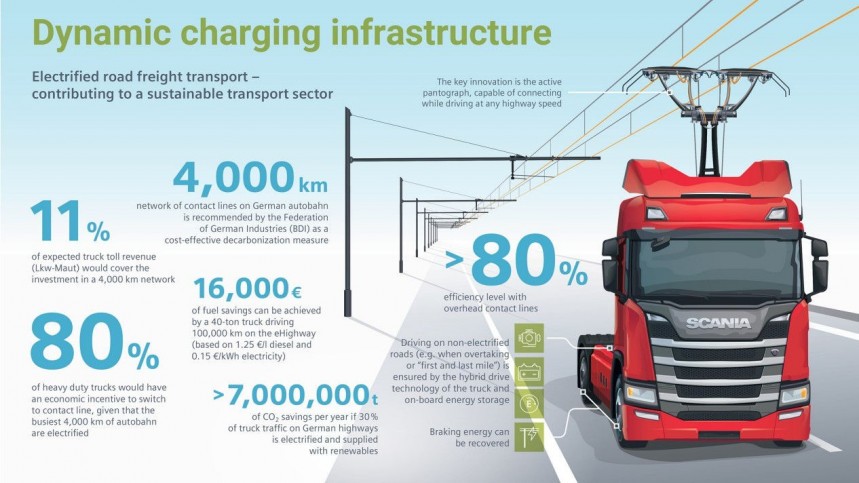

Following good results of field tests, Germany intends to equip a total of 4,000 km (about 2,500 miles) of highway with overhead contact lines by 2030. This would lead to saving more than 7 million tons of CO2 each year.

This would contribute to slashing 40% of GHG emissions from freight transport by the end of this decade. Other companies are exploring this promising concept, while the industry already came up with advanced proposals for standardization.

It also means huge investments for putting in place such an infrastructure. The good news is the costs are estimated on par with plug-in fast-charging similar infrastructure and less than a similar gas station network.

Pantographs are also used in public transport to fast-charge batteries at bus stops. While passengers are on- and offboarding, the pantograph on the roof comes into contact with the special pole system above. It can “flash-charge” the batteries with powers of more than 100 kW, providing enough range till the next stop.

This way of charging is more appropriate for ultracapacitors. These are batteries that store and discharge energy very quickly and effectively. They can’t replace batteries because they aren’t well-suited for long-term energy storage. But they seem like an interesting solution for public transport use.

So, pantographs mounted on passenger cars and SUV roofs are not feasible. Unless…

The eRoadArlanda consortium used a 2 km (1.2-mile) portion of a public road to build an integrated electric rail. It is connected to the power grid and divided into 50-meter (164-foot) long sections that are only powered when vehicles move over them.

The electricity is transferred to the vehicle through a moveable arm placed on the bottom of the vehicle. A sensor detects when the vehicle moves over the rail, and the arm lowers and moves into contact with the rail. When overtaking, the arm automatically raises.

The eRoad pilot was inaugurated in 2017 and used electric trucks for trials. Since then, several other similar projects were deployed. Hey, Elon, did you hear about Elonroad? This Swedish startup is also into road electrification.

Their rail is supposedly capable of feeding up to 350 kW high power to the car, with a 97% efficiency. They even fitted a Tesla with a “mini pantograph” underneath, and Autopilot took care of connecting and disconnecting it from the rail.

That’s why they advertise it as an “infinite range solution.” But what about the costs? Analysts estimate at least €1 million/km ($1.6 million/mile) for two lanes of the electric road. Preliminary calculations show that it takes roughly 10 years for offsetting the cost of gasoline, diesel, and biofuel cars and trucks. Add to this the lack of emissions, and it seems a win-win scenario.

More interesting is the trials in Sweden have showed less than 10% of the entire road network is necessary to be converted into such “electric roads” to achieve road transport emission cuts by 2030. So just imagine the huge positive impact of converting at least half of the roads.

Most concerns are focused on the long-term reliability of such solutions, and potentially electric hazardous situations. There are many challenges fitting roads and highways with millions of poles and kilometers of cables. Consider the violent storms due to climate change, the economic and environmental impact due to the materials demand increase, and so on.

There are also some undeniable advantages to conductive charging. The most important is the need for less large and heavy batteries. It is also a faster way to encourage the electrification of heavy-duty transport, and it is better suited to it.

But for passenger EVs, it’s not quite the real deal to make “range anxiety” history. It’s very close, though. Maybe the secret to success is to get rid of any form of contact between the car and the source of electricity. We’ll take a look at true wireless inductive charging in the next part.

It’s as quick as filling up an ICE car’s tank, then you can travel several hundred miles until you get to another battery swap station. You don’t own the battery; you simply pay for using it in your car. It’s almost the same as paying for the gasoline you burn in your car’s engine.

However, for this technology to be embraced globally, it requires very stringent standardization, and this means limitations to the vehicle and battery design. Also, it’s much more costly than plug-in charging networks, and many fear a monopoly of just a few companies due to patent rights.

So, the industry searched for other solutions to make electric vehicles more user-friendly in terms of long ranges. One of them is conductive charging. You are very familiar with it because of trams and electric trains.

What is conductive charging, anyway?

Try to remember the physics experiments you did in school. I bet the most popular one was putting your hands on a large metal ball while everybody was laughing at you because of your hair. The longer your hair, the funnier you were looking.Your hair was suddenly electrified because you were experimenting with conductive charging. The metal ball was charged, and you were neutral. By touching it with your hands, you were receiving the electrons from the sphere. Depending on the charge, you could even turn on a light bulb in your hand.

It's not a scientifical explanation at all, but it’s easy to understand why trying to touch high-voltage power lines is absolutely stupid. The human body is simply not suited to receive a high amount of electricity. That’s why we hide from lightning in the storm.

Conductive charging in electric traction

You all know that electric locomotives and trams use an extendable arm to stay in touch with the electric cables above. Although similar devices were mentioned by ancient Greeks, the pantograph was invented in the early 1600s by Christoph Scheiner, a German Jesuit priest, physicist, and astronomer in Ingolstadt.The pantographs were mainly used in architecture until another German, Walter Reichel from Siemens & Haiske, used a pantograph as a current collector in 1889. His invention simply consisted of a pantograph mechanism to move up and down a graphite contact strip.

By keeping this strip in contact with the overhead wires, it collects the electrical current and transfers it to the electrical motor. The pantograph can be used either stationary or when the vehicle is moving. That’s why electric locomotives and trams don’t need batteries.

Moving an electric vehicle without the need for a battery?

I think everybody here experienced the funny rides in those bumper little cars at amusement parks or locar fairs. They use conductive charging, you know? I’m sure you remember the pole-mounted contact shoe touching the ceiling where it draws electricity from.Trolleybuses are the best example of wheeled vehicles that don’t stay on fixed railways, like locomotives or trams. Instead of the pantograph, they use much simpler trolley poles as current collectors. The only problem is, once that pole is no longer in contact with the overhead wire, the electric motor stops working.

The electric motor needs electricity, but that’s an understatement. You can feed that electricity by collecting it from somewhere around the vehicle. Or you can feed the electricity stored in a battery. Or you can do both to avoid the previous scenario of no wire contact.

Is conductive charging suitable for electric cars?

We can all agree that putting a pantograph or a trolley pole on a car or SUV’s roof is a terrible idea. Imagine the height and weight of such a device to reach for the wires above. Imagine the complexity of a network of suspended cables in cities, on the roads, and the highways.Someone did. But it’s not about cars, it’s about heavy-duty vehicles. In 2016, Scania and Siemens opened the world’s first eHighway in Sweden. It was a pilot project covering a two-kilometer (1.2 miles) stretch of the E16 highway north of Stockholm.

Authorities and companies mounted on that stretch an overhead catenary wire system on special poles. The vehicles used for the trial were two diesel-hybrid trucks, fitted with pantographs on the driver cabin’s roof. Simply put, rail electrification was transferred to road transport.

Since then, several other trials started throughout Europe. In Germany, recent trials feature electric heavy-duty trucks. When a truck is using the pantograph to feed electricity to the electric motor, its battery is recharged by moving wheels. This way, the truck has enough range when not using the overhead power lines.

Following good results of field tests, Germany intends to equip a total of 4,000 km (about 2,500 miles) of highway with overhead contact lines by 2030. This would lead to saving more than 7 million tons of CO2 each year.

This would contribute to slashing 40% of GHG emissions from freight transport by the end of this decade. Other companies are exploring this promising concept, while the industry already came up with advanced proposals for standardization.

It also means huge investments for putting in place such an infrastructure. The good news is the costs are estimated on par with plug-in fast-charging similar infrastructure and less than a similar gas station network.

This way of charging is more appropriate for ultracapacitors. These are batteries that store and discharge energy very quickly and effectively. They can’t replace batteries because they aren’t well-suited for long-term energy storage. But they seem like an interesting solution for public transport use.

So, pantographs mounted on passenger cars and SUV roofs are not feasible. Unless…

How about feeding the energy from down under?

Instead of using poles and wires high-mounted above car roofs, we could use rails embedded in the road. Does it sound like a wacky idea? Not quite. The funny thing is the world’s first pilot project for such an electrified road comes from Sweden.The eRoadArlanda consortium used a 2 km (1.2-mile) portion of a public road to build an integrated electric rail. It is connected to the power grid and divided into 50-meter (164-foot) long sections that are only powered when vehicles move over them.

The electricity is transferred to the vehicle through a moveable arm placed on the bottom of the vehicle. A sensor detects when the vehicle moves over the rail, and the arm lowers and moves into contact with the rail. When overtaking, the arm automatically raises.

Their rail is supposedly capable of feeding up to 350 kW high power to the car, with a 97% efficiency. They even fitted a Tesla with a “mini pantograph” underneath, and Autopilot took care of connecting and disconnecting it from the rail.

That’s why they advertise it as an “infinite range solution.” But what about the costs? Analysts estimate at least €1 million/km ($1.6 million/mile) for two lanes of the electric road. Preliminary calculations show that it takes roughly 10 years for offsetting the cost of gasoline, diesel, and biofuel cars and trucks. Add to this the lack of emissions, and it seems a win-win scenario.

More interesting is the trials in Sweden have showed less than 10% of the entire road network is necessary to be converted into such “electric roads” to achieve road transport emission cuts by 2030. So just imagine the huge positive impact of converting at least half of the roads.

Can we agree we have a winner?

Well, unfortunately, the answer is no. At least not yet. Conductive charging is very promising because most of the technology has a solid background in rail electrification. Fitting long-haul heavy trucks with pantographs on the roofs or with underneath moveable arms is not too complicated.Most concerns are focused on the long-term reliability of such solutions, and potentially electric hazardous situations. There are many challenges fitting roads and highways with millions of poles and kilometers of cables. Consider the violent storms due to climate change, the economic and environmental impact due to the materials demand increase, and so on.

There are also some undeniable advantages to conductive charging. The most important is the need for less large and heavy batteries. It is also a faster way to encourage the electrification of heavy-duty transport, and it is better suited to it.

But for passenger EVs, it’s not quite the real deal to make “range anxiety” history. It’s very close, though. Maybe the secret to success is to get rid of any form of contact between the car and the source of electricity. We’ll take a look at true wireless inductive charging in the next part.