If you have been following the saga of the Austin-made Model Y with a cracked front casting, it has just reached a new chapter. I have already told my readers when it started and how the depth of the crack was confirmed. Until very recently, the Model Y owner still lacked an official written reply from Tesla, but it has finally arrived. According to the battery electric vehicle (BEV) maker, what Nizar Kamel has in his car is allegedly not a defect; it is a "discontinuity." A forensic specialist told me that's "pseudo-scientific jargon."

You'll remember I always referred to the Model Y owner as NK or Cracked_Tesla, the handle he uses on Reddit. Kamel wanted to keep his name private because he was trying to see if other Tesla Service Centers would give him the explanations he had been looking for in the past four months. However, he shared his story on Elon Musk's social media (whatever it is called nowadays) and used his real name, which led other websites to identify him in their stories – they did not contact him before publishing them. Kamel told me I could now use his real name.

"The other service center wouldn't do anything for me. They actually had the manager from the original call me. The regional manager called me and basically repeated all that was said by the location manager."

It was the regional manager who gave Kamel Tesla's only written response about the crack in his Model Y. Here are the exact words he used:

"The discontinuity found on the Front Casting of this vehicle is inherent to the Die Casting (sic) process. It doesn't represent a risk to vehicle structural integrity, and discontinuities like this have been evaluated to 2.5x expected life of chassis components."

A quick search for the term reveals several pages in which weld specialists state that a discontinuity is not a defect. While the latter demands that the casting is repaired or rejected, a discontinuity is an interruption in the physical continuity of the casting. Another word for it is "imperfection," meaning it does not need to be fixed because the cast part is still within the standard tolerances.

In a way, Tesla confirmed more vehicles are around with these cracks. Otherwise, Tesla would not have referred to "discontinuities like this" or measured how resistant the castings with them still were. If a cracked casting lasts 2.5 times what other chassis components resist, how long can a flawless cast part endure? I'd ask Tesla about that if it talked to the press.

Despite Tesla's written answer to Kamel, no other Austin-made Model Y owner confirmed seeing a cracked front casting in their BEVS. Only two or three told him they would also check, while one or two said their BEVs were normal. I confess I could only confirm one, which means that any other still did not care to check. Considering how many cars Giga Austin has already delivered, a few thousand customers are either in the same situation or trying to solve the matter with Tesla before going public.

This "discontinuity" story has a few flaws. The most important one is that Tesla wondered about buying back Kamel's Model Y. Why would it do that if the vehicle was in perfect shape? Just to avoid the negative media exposure? As tempting as that seemed, he would not be comfortable with the offer.

"The regional manager brought up the option for them to buy back the car from me. They still sound to me as if they are trying to give me the runaround. I would not mind a replacement vehicle and additional compensation as the price is now lower than I paid, except for the fact I would still have to deal with the same managers at the service centers for any issues in the future. The whole ordeal has led to a bad relationship between us, and I don't think it is repairable."

Before that, Tesla proposed to make a cosmetic fix on the cracked component, but would it be really just cosmetic? If the casting is in good shape but needs to look better, why wasn't it fixed before leaving the factory? This is what Kamel asked for: a technical explanation that made him sure his car would not have a catastrophic failure. The BEV maker just said – through its regional manager – that the Model Y's discontinuity was "within specs."

"He just kept repeating that statement above and that it was common on die-cast parts. When I asked follow-up questions – such as, 'Can you provide examples on other Tesla vehicles?,' 'Is there any future action plan on Tesla's end if the cracks grow?,' and 'Can I get something more official that the engineers signed off on?' – he said that statement is the most official thing I will get from Tesla and that if something happens in the future, I can use that as proof the car was 'safe.'"

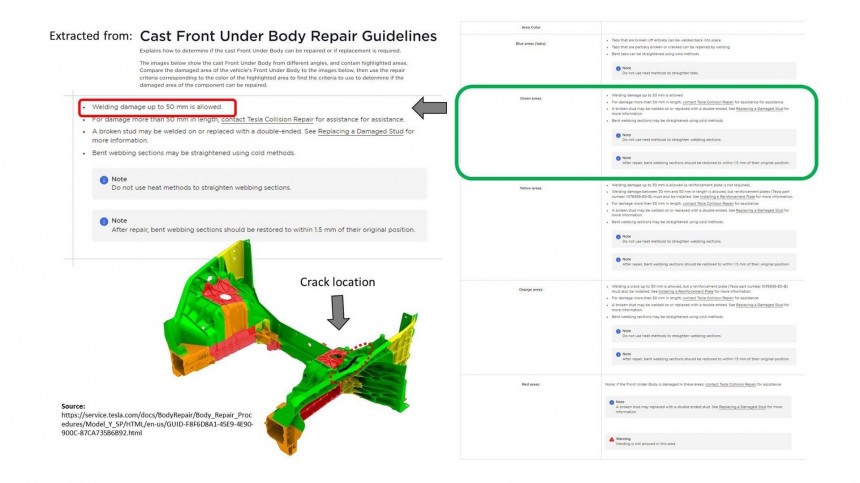

Ironically, if something happened to his Model Y due to the "discontinuity," that statement would prove that Tesla was concealing a more severe problem, which is precisely what Kamel fears. That is even stronger after a commenter showed him Tesla's "Model Y Collision Repair Procedures Manual." More specifically, the "Cast Front Under Body Repair Guidelines" section.

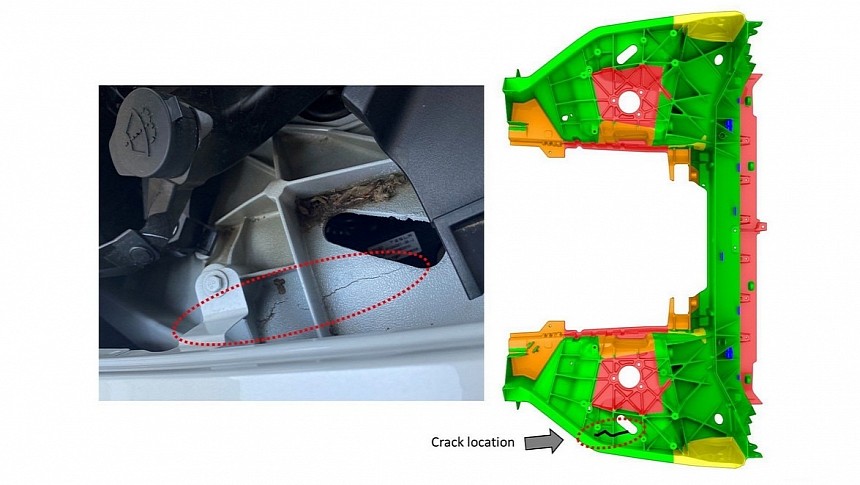

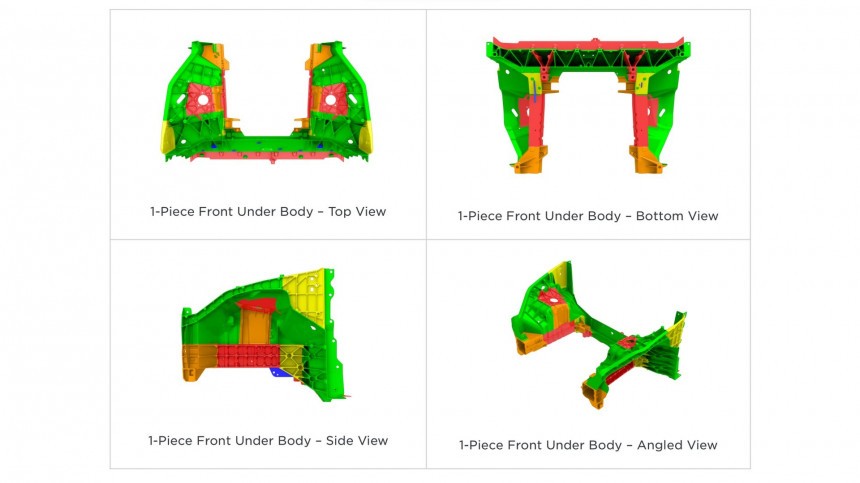

In that document, Tesla describes how the component needs to be repaired. Summing up, it depends on where the damage occurred. Tesla created a colored image of the front casting with areas painted blue, green, yellow, orange, and red. The blue ones are those that accept more repairs. Green ones require a more careful analysis: weld repairs may not exceed 50 millimeters (1.97 inches). Anything larger than that requires you to contact Tesla Collision Repair, which is probably an engineering team that can say if the repair is possible or not. I'd try to confirm that if it were possible.

Orange and red areas are the more sensitive ones. Anything in the red area requires the technicians to contact Tesla Collision Repair. That probably means the entire component needs a replacement – if that is economically feasible. If it is not, the car is probably a write-off candidate. That is one of the reasons for BMW to say that there are "much more efficient ways to build a car body" and that repairs in such components would be "too expensive."

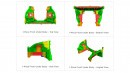

Kamel measured the crack in his Model Y's front casting. It is 2.2 inches (55.9 mm) if you consider it ends in the tab that separates it from two other cracks. It is probably bigger underneath the tab, meaning it just divided a more extended failure. How can this "discontinuity" present no risk if it is longer than the damages Tesla allows technicians to repair? Is it the case that blue and green areas in the front casting do not perform relevant structural functions? Nobody at Tesla answered these questions to the Model Y owner in the past four months. Kamel counts only two, but that's generous of him to do so.

Very few people accept talking about Tesla on or even off the record. More than fearing retaliation, some engineers do not want to shut down possible employment opportunities at the BEV maker – you never know, right? That was when I remembered that Costas Lakafossis is an accident investigator and an engineer. As you'll recall, he has given relevant insight on sudden unindented acceleration (SUA) episodes involving Tesla vehicles and even petitioned the National Highway Traffic Safety Administration (NHTSA) to suggest a solution for them.

Lakafossis checked the pictures Kamel published and clarified the situation more than Tesla did so far.

"OK, there are two sides here: yes, it is safe, but it is definitely a defect, and it shows very poor manufacturing processes and very poor quality control."

The engineer told me more about these two aspects of the case.

"This particular crack does not pose any risk to the structural integrity of the car because it is located above and away from the top shock mount. But I would never trust a manufacturer that missed this obvious manufacturing defect because next time, this "discontinuity" might happen in another place that poses a real danger."

If you check the colored front cast underbody structure images Tesla created, they make Lakafossis' point even more evident. Considering where the cracks are, only the left front fender would be affected if it broke in a predictable way. However, what the engineer stressed is more important than the diagnostic: if Tesla used a clearly defective component in a production car, what if it presents other cracks in less visible parts of the vehicle? The engineer reinforces how crucial that is to the whole discussion this episode brought up.

"Their explanation of this being a 'discontinuity and not a defect' is pseudo-scientific jargon that means nothing really: a 'discontinuity' is a casting defect, and that is exactly the reason that we have quality control in all casting processes: to reject any castings that are not 100% perfect."

It is worth remembering why Kamel discovered the issue in the first place: a Reddit thread reported a case in which a Model Y did not have a brake fluid reservoir cap. To be on the safe side, he decided to check his BEV, removed the plastic cover that hides that reservoir, and discovered the cracks. In other words, he targeted a quality control flaw and hit another. It is difficult to determine which one is worse: a crack in the vehicle's structure or failing brakes when you need them the most. Kamel said he would keep pushing back for a reasonable solution. So would I.

"The other service center wouldn't do anything for me. They actually had the manager from the original call me. The regional manager called me and basically repeated all that was said by the location manager."

"The discontinuity found on the Front Casting of this vehicle is inherent to the Die Casting (sic) process. It doesn't represent a risk to vehicle structural integrity, and discontinuities like this have been evaluated to 2.5x expected life of chassis components."

A quick search for the term reveals several pages in which weld specialists state that a discontinuity is not a defect. While the latter demands that the casting is repaired or rejected, a discontinuity is an interruption in the physical continuity of the casting. Another word for it is "imperfection," meaning it does not need to be fixed because the cast part is still within the standard tolerances.

In a way, Tesla confirmed more vehicles are around with these cracks. Otherwise, Tesla would not have referred to "discontinuities like this" or measured how resistant the castings with them still were. If a cracked casting lasts 2.5 times what other chassis components resist, how long can a flawless cast part endure? I'd ask Tesla about that if it talked to the press.

This "discontinuity" story has a few flaws. The most important one is that Tesla wondered about buying back Kamel's Model Y. Why would it do that if the vehicle was in perfect shape? Just to avoid the negative media exposure? As tempting as that seemed, he would not be comfortable with the offer.

"The regional manager brought up the option for them to buy back the car from me. They still sound to me as if they are trying to give me the runaround. I would not mind a replacement vehicle and additional compensation as the price is now lower than I paid, except for the fact I would still have to deal with the same managers at the service centers for any issues in the future. The whole ordeal has led to a bad relationship between us, and I don't think it is repairable."

"He just kept repeating that statement above and that it was common on die-cast parts. When I asked follow-up questions – such as, 'Can you provide examples on other Tesla vehicles?,' 'Is there any future action plan on Tesla's end if the cracks grow?,' and 'Can I get something more official that the engineers signed off on?' – he said that statement is the most official thing I will get from Tesla and that if something happens in the future, I can use that as proof the car was 'safe.'"

Ironically, if something happened to his Model Y due to the "discontinuity," that statement would prove that Tesla was concealing a more severe problem, which is precisely what Kamel fears. That is even stronger after a commenter showed him Tesla's "Model Y Collision Repair Procedures Manual." More specifically, the "Cast Front Under Body Repair Guidelines" section.

Orange and red areas are the more sensitive ones. Anything in the red area requires the technicians to contact Tesla Collision Repair. That probably means the entire component needs a replacement – if that is economically feasible. If it is not, the car is probably a write-off candidate. That is one of the reasons for BMW to say that there are "much more efficient ways to build a car body" and that repairs in such components would be "too expensive."

Kamel measured the crack in his Model Y's front casting. It is 2.2 inches (55.9 mm) if you consider it ends in the tab that separates it from two other cracks. It is probably bigger underneath the tab, meaning it just divided a more extended failure. How can this "discontinuity" present no risk if it is longer than the damages Tesla allows technicians to repair? Is it the case that blue and green areas in the front casting do not perform relevant structural functions? Nobody at Tesla answered these questions to the Model Y owner in the past four months. Kamel counts only two, but that's generous of him to do so.

Lakafossis checked the pictures Kamel published and clarified the situation more than Tesla did so far.

"OK, there are two sides here: yes, it is safe, but it is definitely a defect, and it shows very poor manufacturing processes and very poor quality control."

The engineer told me more about these two aspects of the case.

"This particular crack does not pose any risk to the structural integrity of the car because it is located above and away from the top shock mount. But I would never trust a manufacturer that missed this obvious manufacturing defect because next time, this "discontinuity" might happen in another place that poses a real danger."

"Their explanation of this being a 'discontinuity and not a defect' is pseudo-scientific jargon that means nothing really: a 'discontinuity' is a casting defect, and that is exactly the reason that we have quality control in all casting processes: to reject any castings that are not 100% perfect."

It is worth remembering why Kamel discovered the issue in the first place: a Reddit thread reported a case in which a Model Y did not have a brake fluid reservoir cap. To be on the safe side, he decided to check his BEV, removed the plastic cover that hides that reservoir, and discovered the cracks. In other words, he targeted a quality control flaw and hit another. It is difficult to determine which one is worse: a crack in the vehicle's structure or failing brakes when you need them the most. Kamel said he would keep pushing back for a reasonable solution. So would I.