The Ford Mustang is America's favorite muscle car. It has been so for years, leaving the Chevrolet Camaro and the Dodge Challenger in a cloud of dust in 2023 as well. And this is how it is manufactured.

The Mustang rolls off the production line at the Ford Flat Rock Assembly Plant in Detroit, Michigan. The facility is one of the most modern and technologically advanced Ford factories.

When a car is supposed to see the light of day, the process starts with the artists sketching out their ideas for the upcoming vehicle, drawing it either by hand or using Computer Aided Design software.

The next step is clay modeling. Ford uses industrial plasticine, which is more durable and does not dry out or crack over time. It is also easy to model, helping sculptors to make seamless transitions between surfaces.

Clay models undergo several wind tunnel tests, each test focusing on a particular aerodynamic characteristic.

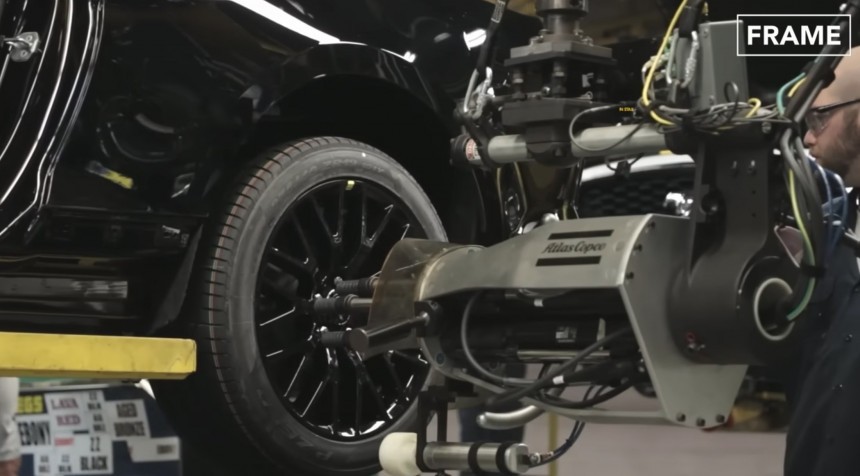

The video uploaded on the Frame YouTube channel takes us along the assembly line of the Ford Mustang Bullit, which shares its steel unibody with the Mustang GT350. Its panels are manufactured by stamping, a common procedure in the industry.

Once the panels are assembled, the lights are positioned with extreme precision, and so is the radiator grille with its blacked-out finish.

Helper arms assist in the installation and alignment of the seats inside the cabin. Along the production line, upper-body exoskeletons, specifically designed to reduce fatigue and the risk of injuries, lift heavy objects.

The steering wheel is secured to the steering column and the steering wheel airbag using bolts and center-locking nuts. Meanwhile, the workers use a strong adhesive on the underside of the gearshift knob. Multi-spindle tools are used to tighten or loose nuts, and they can do so on multiple nuts at the same time.

After being primed, the vehicle is painted in several layers. The first of them is the base coat, and that is also the color selected for the car. The clear coat is applied last to protect the base coat and give it a shiny finish.

The Ford Mustang Bullit is powered by a 5.0-liter V8 engine that generates 480 horsepower and 420 pound-feet of torque. The engine is linked to a six-speed manual transmission and a limited-slip differential. The car is equipped with Brembo brakes and Bilstein shocks and sports a unique suspension tuning for that raw feeling behind the steering wheel.

The next step up is the light tunnel. Such light tunnels are specifically designed to help identify defects that might not be visible in normal lighting conditions. Furthermore, the experts check the engine and transmission for any leaks, noise, or unwanted vibrations, as well as fluid levels.

There is also a team checking the dashboard and instrument panel for any dents, while windows are inspected for cracks, chips, or scratches.

Before they are shipped from the factory to the dealerships, the cars undergo a pre-shipment inspection. If they pass the test, they go into the dedicated washing and cleaning area. This stage is supposed to remove any dirt, debris, and manufacturing residue, as well as grease and oil. High-pressure air jets dry the car, removing any water spots.

There is one more step before getting the car on a load truck or cargo ship. A film covers several surfaces of the vehicle to prevent them from getting scratched or dented during transportation.

To make sure the Fords are safe once they hit the road, the carmaker also puts them in safety tests. Furthermore, tests run by car safety performance assessment programs confirm their crashworthiness. A frontal crash test puts the car face to face with a deformable barrier at 40 mph. During a side impact test, a moving deformable barrier slams into the vehicle at 31 mph.

Such tests check if the structure of the Mustang, or any car for that matter, can withstand the impact and dissipate the energy without causing serious injuries to those onboard.

When a car is supposed to see the light of day, the process starts with the artists sketching out their ideas for the upcoming vehicle, drawing it either by hand or using Computer Aided Design software.

The next step is clay modeling. Ford uses industrial plasticine, which is more durable and does not dry out or crack over time. It is also easy to model, helping sculptors to make seamless transitions between surfaces.

Clay models undergo several wind tunnel tests, each test focusing on a particular aerodynamic characteristic.

Once the panels are assembled, the lights are positioned with extreme precision, and so is the radiator grille with its blacked-out finish.

Helper arms assist in the installation and alignment of the seats inside the cabin. Along the production line, upper-body exoskeletons, specifically designed to reduce fatigue and the risk of injuries, lift heavy objects.

The steering wheel is secured to the steering column and the steering wheel airbag using bolts and center-locking nuts. Meanwhile, the workers use a strong adhesive on the underside of the gearshift knob. Multi-spindle tools are used to tighten or loose nuts, and they can do so on multiple nuts at the same time.

After being primed, the vehicle is painted in several layers. The first of them is the base coat, and that is also the color selected for the car. The clear coat is applied last to protect the base coat and give it a shiny finish.

The next step up is the light tunnel. Such light tunnels are specifically designed to help identify defects that might not be visible in normal lighting conditions. Furthermore, the experts check the engine and transmission for any leaks, noise, or unwanted vibrations, as well as fluid levels.

There is also a team checking the dashboard and instrument panel for any dents, while windows are inspected for cracks, chips, or scratches.

Before they are shipped from the factory to the dealerships, the cars undergo a pre-shipment inspection. If they pass the test, they go into the dedicated washing and cleaning area. This stage is supposed to remove any dirt, debris, and manufacturing residue, as well as grease and oil. High-pressure air jets dry the car, removing any water spots.

To make sure the Fords are safe once they hit the road, the carmaker also puts them in safety tests. Furthermore, tests run by car safety performance assessment programs confirm their crashworthiness. A frontal crash test puts the car face to face with a deformable barrier at 40 mph. During a side impact test, a moving deformable barrier slams into the vehicle at 31 mph.

Such tests check if the structure of the Mustang, or any car for that matter, can withstand the impact and dissipate the energy without causing serious injuries to those onboard.