Volkswagen embraced the electric mobility shift by retooling many of its current factories to manufacture only EVs, with Zwickau, Germany, being the first. Ford seems to have decided it needed an entirely new industrial complex to do the same. That’s the purpose of the Blue Oval City, a manufacturing facility in Stanton, Tennessee, that will be dedicated to producing electric F-Series vehicles and employ around 6,000 people.

Ford and SK Innovation will invest $5.6 billion in Blue Oval City, which will also produce batteries and recycle them. The BlueOval SK cell plant is just one of the facilities that Ford will have for making batteries. The carmaker announced another two.

They will be built in Glendale, Kentucky, thanks to a $5.8 billion investment made both by Ford and SK Innovation. In these two battery factories, the partners expect to employ 5,000 people and produce cells for future Ford and Lincoln electric cars. The three battery plants will deliver 129 GWh per year in components, 86 GWh of which will come from the twin Kentucky factories.

Ford expects all factories to be operational by 2025. That means Blue Oval City will be in charge of presenting the second generation of the F-150 Lightning powered only by electrons. The new pickup truck will be built on a dedicated electric platform called TE1 that Ford said it would present in 2025. What a coincidence, right?

The Kentucky cell plants will probably supply cells for the GE2 platform, another dedicated electric architecture that will underpin the second-generation Mustang Mach-E and possibly the first electric Mustang Coupe/Convertible. Ford will present this new platform by mid-2023.

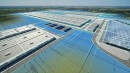

Built on a 3,600-acre campus, Ford’s Blue Oval City wants to be carbon-neutral and adopt zero-waste-to-landfill processes. That means all byproducts of manufacturing will either be recycled in the complex or sent somewhere that can do that. Local renewable energy sources are considered to help power operations.

Apart from verticalizing production – manufacturing many of the components it needs on its own – Ford also wants suppliers to be in the complex, saving carbon emissions and making production more efficient.

They will be built in Glendale, Kentucky, thanks to a $5.8 billion investment made both by Ford and SK Innovation. In these two battery factories, the partners expect to employ 5,000 people and produce cells for future Ford and Lincoln electric cars. The three battery plants will deliver 129 GWh per year in components, 86 GWh of which will come from the twin Kentucky factories.

Ford expects all factories to be operational by 2025. That means Blue Oval City will be in charge of presenting the second generation of the F-150 Lightning powered only by electrons. The new pickup truck will be built on a dedicated electric platform called TE1 that Ford said it would present in 2025. What a coincidence, right?

The Kentucky cell plants will probably supply cells for the GE2 platform, another dedicated electric architecture that will underpin the second-generation Mustang Mach-E and possibly the first electric Mustang Coupe/Convertible. Ford will present this new platform by mid-2023.

Built on a 3,600-acre campus, Ford’s Blue Oval City wants to be carbon-neutral and adopt zero-waste-to-landfill processes. That means all byproducts of manufacturing will either be recycled in the complex or sent somewhere that can do that. Local renewable energy sources are considered to help power operations.

Apart from verticalizing production – manufacturing many of the components it needs on its own – Ford also wants suppliers to be in the complex, saving carbon emissions and making production more efficient.