Although carmakers and buyers alike came to the conclusion that EV adoption has slowed, sales numbers show a different picture. The trend will only accelerate next year when new technologies are expected to change the electromobility landscape. Here's everything that we should keep an eye on in 2024 as far as EV tech is concerned.

Although many legacy carmakers have seen their EV hopes crushed after disappointing results, EV sales continued to eat into the ICE vehicle market. Tesla bucked the trend, extending a commanding lead over other carmakers in the EV arena. Going into 2024, the EV market leader will continue to set the pace thanks to its technological advancement, while others will try to copy everything Tesla announces.

In retrospect, 2023 has been a mixed bag, as not all the predictions I made earlier in the year materialized. Call me an optimistic, but I wish battery tech advanced at a faster pace. Two up-and-coming battery technologies are yet to prove their worth. Solid-state batteries are still not production-ready despite being developed by many battery companies and startups. Tesla is still grappling with its 4680 cell production and the technologies it announced years ago: dry battery electrode and silicon anode.

Despite these setbacks, I'm not ready to admit that 2023 was a failure, despite GM, Ford, and Volkswagen throwing in the towel. Sure, building electric vehicles is tough, especially when you're very late at the table. Still, Tesla proved that innovation in the car industry is far from getting to a standstill, and we're likely to see many 2023 trends accelerating next year. That being said, let's delve deeper into battery and EV technologies that will shape our lives in 2024.

As Tesla ramped up production and launched the Model 3 in 2017, almost everybody, save for the die-hard Tesla fans, believed that legacy carmakers would wipe out Tesla. Indeed, building electric vehicles should be a walk in the park for GM, Ford, and the like once they throw their virtually unlimited resources into it. Tesla only had a factory in Fremont and was still trying to figure out what makes a car a car.

During those days, I heard the words "Competition is coming" more times than I can remember. Every electric vehicle announced was instantly elevated to the ranks of a "Tesla killer." Even today, when Tesla utterly destroys the competition, I sometimes stumble upon a Tesla killer headline, and it's not even funny anymore. Nobody is going to kill Tesla, except maybe Elon Musk or Tesla itself, but otherwise, it's too big of a chunk for anyone to eat.

Even if companies like BYD in China threaten to surpass Tesla by selling more EVs, that won't change much in the grand scheme of things. It's like saying that a volume automaker like Volkswagen will kill Ferrari because it sells more cars. Seeing how fast Tesla has changed the automotive industry and innovates not only the EV sector but also the automobile as a concept, I am confident nobody will kill Tesla. However, they will try hard to copy it.

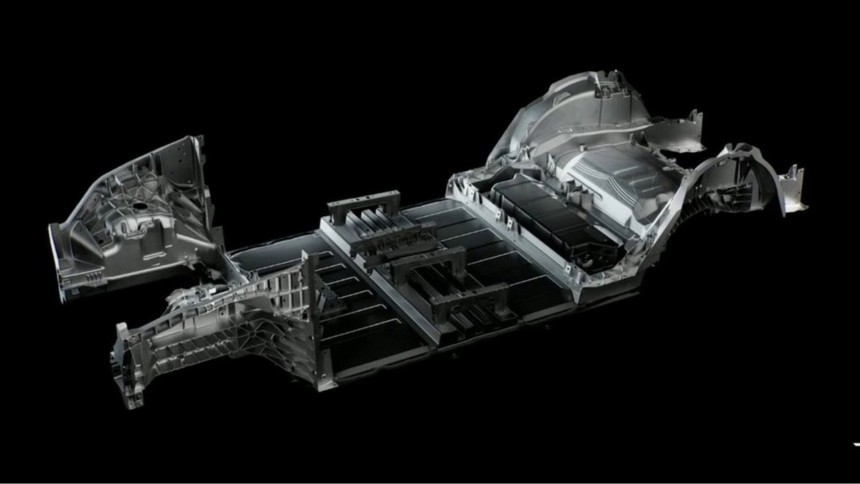

Every new Tesla model has changed the industry in ways nobody has foreseen, especially at launch. The Roadster has shown that an electric car can be both sporty and desirable. The Model S proved that EVs can be sexy and luxurious. The Model 3 brought electromobility to the masses, upending the industry. The Model Y introduced megacastings and structural battery packs, but none of them is as exciting as the Cybertruck.

Tesla electric pickup, however late to the game, is here to change the industry yet again. It might be hard to mass produce, more expensive than anticipated, and with a lower range than advertised, but that won't matter much. The seeds it planted will bear fruits later down the road, and in 2024, they will become visible as the production ramps.

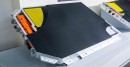

However, the magic will only happen when other carmakers will adopt the 48-volt architecture. EV makers are already abandoning the 12-volt lead-acid batteries in favor of Li-ion equivalents. This will accelerate the transition. Ford CEO Jim Farley has already announced that he is contemplating adopting the higher-voltage architecture in its future vehicles. Other carmakers will do the same.

Tesla has already sent the white papers of the new technology to the auto industry leaders. This will only help accelerate the adoption. We've seen this with the NACS charging port, which Tesla had little difficulty imposing as a new industry standard. I do not doubt that next year, we will see at least one new non-Tesla electric vehicle being powered by a 48-volt system. This voltage has more profound implications than just saving money and weight. It is closely interconnected with the next technology that I believe will make inroads into 2024.

Tesla put it to work marvelously in the Cybertruck's steer-by-wire system. Thanks to the low latency interconnect, the Cybertruck steers more accurately. Classic steering systems use rods and couplings to transmit the steering wheels' movements to the wheels. You might not be aware, but these couplings are not fixed, they have a small play. This adds a sort of physical "latency" to the steering, which the Cybertruck lacks. The steering motors on each axle will steer the wheels with almost zero latency (Tesla said half a millisecond).

Tesla Cybertruck is not the first car to use a steer-by-wire system, but it's the first to implement an aviation-grade system with triple redundancy. The advantages are too significant to be overlooked, which is why I believe this is another EV tech that will gain traction next year. Even if legacy carmakers will look the other way, many Chinese companies will copy this like there's no tomorrow.

Bizarrely, the Model 3 Highland produced at Giga Shanghai doesn't appear to use megacastings. This might change at any time, though, as Tesla also silently adopted megacastings for the Model Y in 2021. However, the Cybertruck is made with huge die-cast structures. The electric pickup has a front single-piece megacasting, while the rear assembly is made of several die-cast structures bonded together. This allowed Tesla to use smaller die-cast machines than it initially considered.

Since it introduced megacastings in 2021, Tesla has improved both the metal alloy composition and the megacastings' structure. This gives it an edge as many other carmakers rush to adopt the new manufacturing technique. For instance, Xpeng needs a 12,000-ton Giga Press to make the rear structure of the X9 SUV, while a 7,000-ton piece makes the front megacasting. Thanks to these optimizations, Tesla only needs one 6-500-ton Giga Press for the Cybertruck's front structure and two 9,000-ton machines for the rear megacasting.

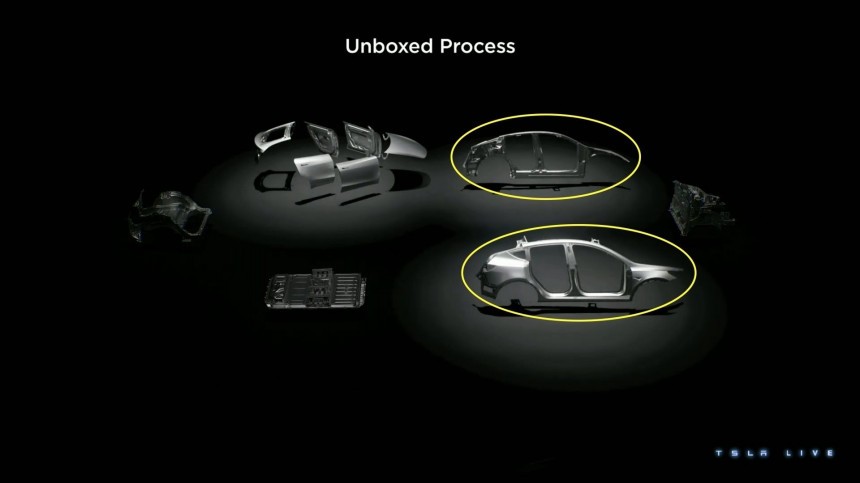

In traditional manufacturing, cars are built by stamping the body parts and assembling them for painting. Later, the doors are removed to install internal components, and then added back. Tesla's unboxed vehicle system divides the process into two critical workflows. The stamped parts, including the body sides and the car's floor, are processed in one workflow. The other workflow takes care of casting the front, rear, and possibly other body parts. Later, they are all put together in the final assembly, thus eliminating some manufactuyring steps and individual components.

We first learned about the unboxed vehicle manufacturing process in March, when Tesla announced the next-generation EV platform during 2023 Investor Day. The manufacturing breakthrough should bring significant cost savings that will allow Tesla to offer a $25,000 electric vehicle. Although Tesla has not finalized the blueprints of the new manufacturing process, this will undoubtedly happen in 2024. The first place to get an unboxed vehicle manufacturing line will be Giga Texas, with Giga Mexico following later.

Together with the megacastings, this is another manufacturing innovation that will see larger adoption throughout the automotive industry. The only thing that prevents other carmakers from announcing a similar process is that they still haven't figured out what Tesla has in mind. Once the first production line starts production, there will surely be followers.

However, things finally got back on track in 2023, and next year, things will only get better. A recent BloombergNEF study showed that battery prices fell a whopping 14% in 2023 to a record low of $139/kWh. Although this is far from the $100/kWh magic threshold, things are not the same in every market. The cheapest battery cells are in China, with an average price of $126/kWh, while in the US and Europe, prices are 11% and 26% higher, respectively.

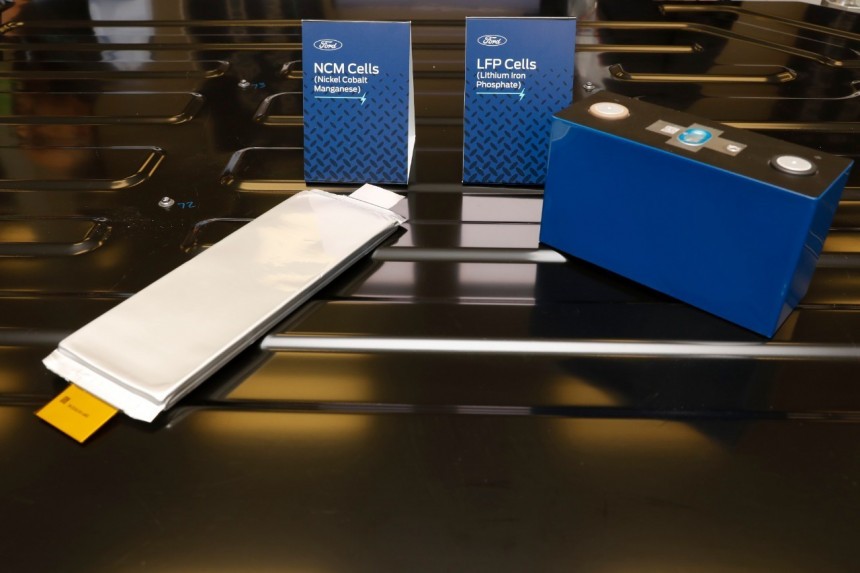

Several studies predict the nickel manganese cobalt (NMC) Li-ion battery pack prices will fall below US$100/kWh by 2027. Meanwhile, the more affordable lithium iron phosphate (LFP) packs are expected to hit the sub-$100 threshold by 2025. Again, these price points will be hit quicker in China, with the US and Europe lagging. However, there's an accelerated trend toward wider LFP cell adoption, and that could bring down the battery prices sooner than anticipated.

Although some legacy carmakers like Ford and GM put new battery plant plans on hold, more carmakers and battery manufacturers are planning LFP cell factories in the US. Thanks to the incentives of the Inflation Reduction Act (IRA), the US market is a honeypot for battery makers. This means that more companies will enter the market, some developing their own LFP cells.

Hyundai was among the latest to announce the development of new LFP battery cells. Although they will not arrive earlier than 2025, this is just offering us a taste of what to expect from the industry leaders starting next year. Hyundai is bullish on LFP cells, claiming it can improve LFP cells' energy density to get on par with premium NMC cells.

Geely in China is also stepping up LFP research efforts through its Zeekr premium brand. Unlike other battery makers, Zeekr is focusing its energy on developing ultra-fast-charging LFP cells. Zeekr claims it achieved a 4.5C charging rate for its "Golden Battery." Considering that 1C means a full charge in one hour, this means the Golden Battery can theoretically take a full charge in 13 minutes. That's even faster than CATL's ShenXing battery, another ultra-fast-charging LFP battery with a 4C charging rate.

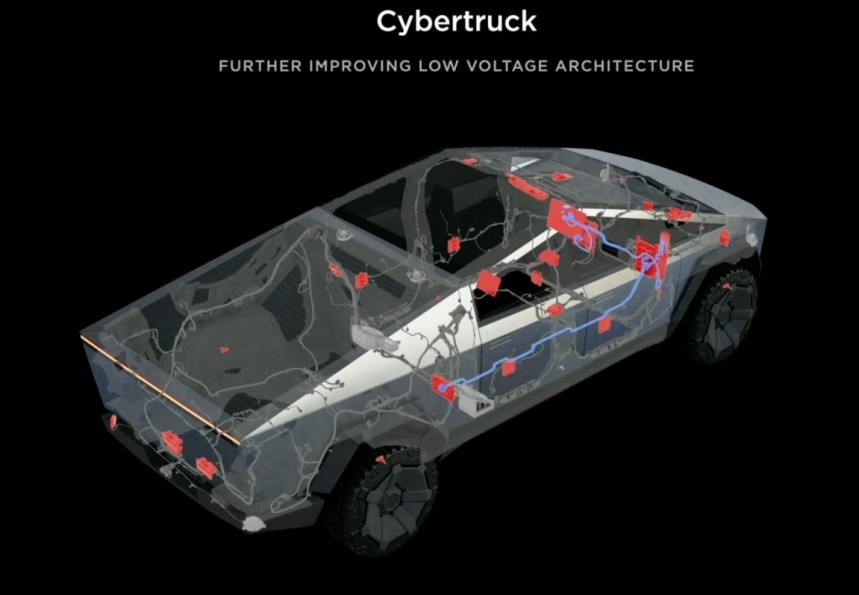

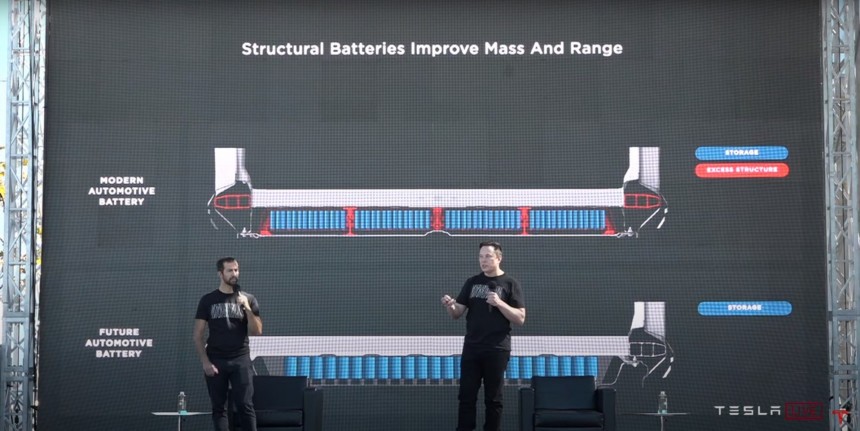

Among them are Tesla's 4680 cells, now in their second generation. Tesla announced the 4680 cells during 2020 Battery Day, promising five times more energy, 16% more range, and six times more power than 2170 cells. However, the new cells are still behind the older cells in terms of energy density and charging performance. Although Tesla installed the second generation of these cells in the Cybertruck, they are still not up to snuff.

The lackluster 4680 cell performance is the reason Cybertruck was announced with a disappointing range. Instead of the promised 500-mile (805 km) mark, the tri-motor variant of the Cybertruck only goes 320 miles (515 km) on a charge. However, real-world reports from owners who already got Tesla's electric pickup show that the range is less than 300 miles (483 km). Also, charging is much slower than expected, a problem we've also seen on the 4680-cell Model Ys.

Hopefully, Tesla will take 4680-cell performance up a notch in 2024. Several things could turn the tide, and using a silicone anode is one of them. Tesla announced a silicon anode at Battery Day 2020, but that hasn't materialized yet. When it will, the energy density and charging performance of battery cells will improve tremendously. The dry battery electrode (DBE) manufacturing process is also very promising, although still not production-ready. The DBE process will help Tesla lower manufacturing times and costs.

NIO was among the first carmakers to show a production-ready solid-state battery. The ET7 prototype traveled 649 miles (1,044 km) on a charge, with 3% of the battery energy left at the end of the trip. The solid-stated battery pack used cells developed by NIO's partner, WeLion. The 150-kWh battery pack weighed 575 kilograms (1,268 pounds), which points to an energy density of 260 Wh/kg.

The solid-state battery is the same size as NIO's liquid-electrolyte batteries currently in production, which have 100 kWh capacity at most. WeLion is confident it could start mass production in April 2024. CATL and Our Next Energy (ONE) are also working on their own solid-state battery cells, which are now in the testing phase. Both companies expect their work to become production-ready by the end of next year.

However, the technology is more of a proof of concept for now. Drive Pilot's many limitations mean the system can only be used on certain pre-mapped highways in Nevada and California. It can also drive semi-autonomously only in ideal weather conditions when you're traveling below 40 mph (64 kph) and only if there's a car in front to follow. The system is also unable to operate if the sun blinds the car's cameras.

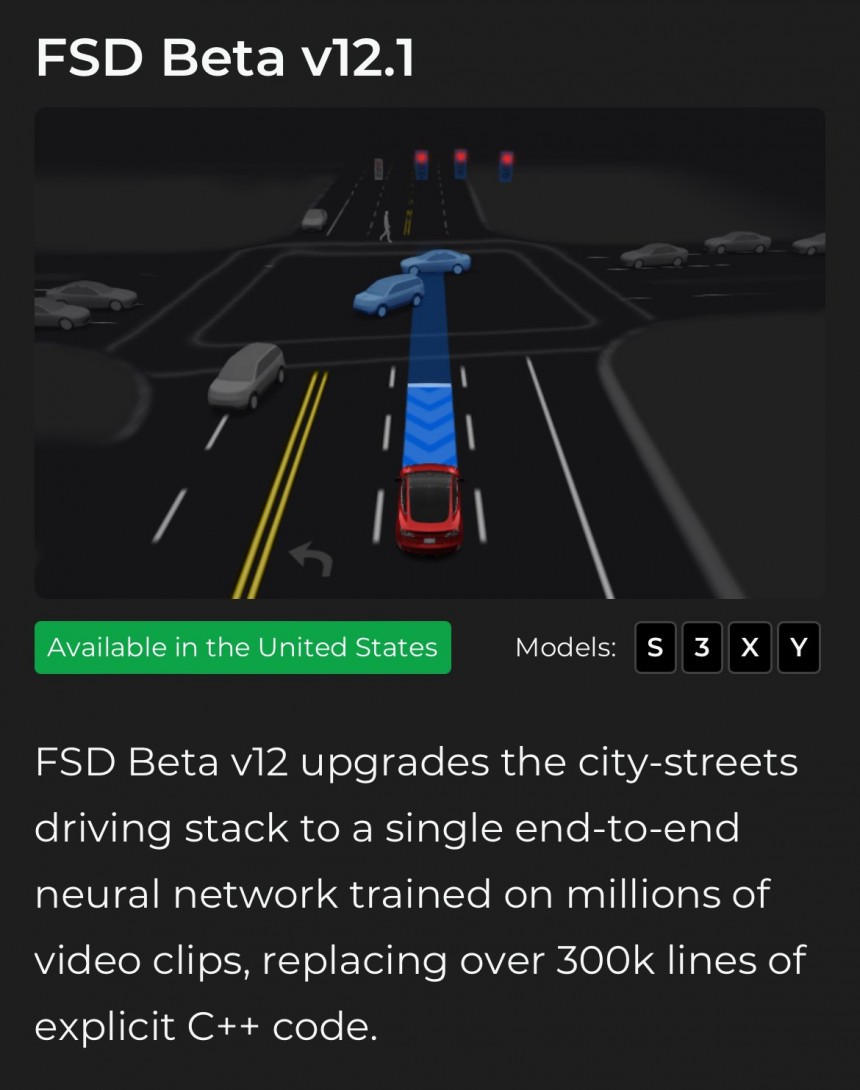

Although Tesla says FSD Beta is an SAE Level 2 driver assist system, it is, in fact, far more capable than Drive Pilot. FSD Beta can drive with minimal driver intervention on highways, city streets, and even on unmarked roads. Tesla thinks FSD will eventually get better and safer than humans, although it currently requires the driver to be ready to take back control at any moment. The EV startup has recently enhanced its driver monitoring system to make sure the drivers stay alert.

Tesla is currently testing the 12th iteration of the software, which uses a single end-to-end neural network. This replaces both the city streets driving stack and the highway driving stack. It also means that Tesla is slashing more of the legacy C++ code and replacing it with neural networks. The aim is to make FSD Beta end-to-end AI, from images in, to controls out. For now, the latest FSD variant is reserved for Tesla employee vehicles, but it will go wide to customer vehicles in 2024.

In retrospect, 2023 has been a mixed bag, as not all the predictions I made earlier in the year materialized. Call me an optimistic, but I wish battery tech advanced at a faster pace. Two up-and-coming battery technologies are yet to prove their worth. Solid-state batteries are still not production-ready despite being developed by many battery companies and startups. Tesla is still grappling with its 4680 cell production and the technologies it announced years ago: dry battery electrode and silicon anode.

Despite these setbacks, I'm not ready to admit that 2023 was a failure, despite GM, Ford, and Volkswagen throwing in the towel. Sure, building electric vehicles is tough, especially when you're very late at the table. Still, Tesla proved that innovation in the car industry is far from getting to a standstill, and we're likely to see many 2023 trends accelerating next year. That being said, let's delve deeper into battery and EV technologies that will shape our lives in 2024.

Tesla thrusts the industry into the future all by itself

In the early days, Tesla was considered more like a curiosity than a car company. Nobody in their right mind thought that electric vehicles would have a chance to replace combustion engine cars. At the time, the Roadster had an eye-watering price, and even the Model S was seen as a reach-boy toy than a luxury car. Other electric models on the market, like the Nissan Leaf, were more affordable but looked ugly as hell and were too impractical to be taken seriously.During those days, I heard the words "Competition is coming" more times than I can remember. Every electric vehicle announced was instantly elevated to the ranks of a "Tesla killer." Even today, when Tesla utterly destroys the competition, I sometimes stumble upon a Tesla killer headline, and it's not even funny anymore. Nobody is going to kill Tesla, except maybe Elon Musk or Tesla itself, but otherwise, it's too big of a chunk for anyone to eat.

Even if companies like BYD in China threaten to surpass Tesla by selling more EVs, that won't change much in the grand scheme of things. It's like saying that a volume automaker like Volkswagen will kill Ferrari because it sells more cars. Seeing how fast Tesla has changed the automotive industry and innovates not only the EV sector but also the automobile as a concept, I am confident nobody will kill Tesla. However, they will try hard to copy it.

Every new Tesla model has changed the industry in ways nobody has foreseen, especially at launch. The Roadster has shown that an electric car can be both sporty and desirable. The Model S proved that EVs can be sexy and luxurious. The Model 3 brought electromobility to the masses, upending the industry. The Model Y introduced megacastings and structural battery packs, but none of them is as exciting as the Cybertruck.

The 48-volt electrical system will see wider adoption

This is one of the more understated technologies that Tesla Cybertruck will bring to the table. It's not the first time that the auto industry has tried to move to a higher voltage, but this time, it has a chance to succeed. The Cybertruck might not reach the high volumes Tesla expects in 2024, but the 48-volt electrical system will trickle down to other Tesla models. The next-generation EVs will only appear in 2025 at the earliest, but I'm sure we'll learn from prototypes that they will move to the higher voltage.However, the magic will only happen when other carmakers will adopt the 48-volt architecture. EV makers are already abandoning the 12-volt lead-acid batteries in favor of Li-ion equivalents. This will accelerate the transition. Ford CEO Jim Farley has already announced that he is contemplating adopting the higher-voltage architecture in its future vehicles. Other carmakers will do the same.

Gigabit Ethernet backbone for everyone

Gigabit Ethernet in automotive might not sound like a breakthrough addition, but it is. Although the auto industry has used ethernet before, Tesla set the tone for a much faster connection with negligible latency. Incidentally, it also supports Power over Ethernet, which also works at 48 volts. This makes these two technologies a marriage made in heaven and likely to see wider adoption than either of them taken separately.Tesla put it to work marvelously in the Cybertruck's steer-by-wire system. Thanks to the low latency interconnect, the Cybertruck steers more accurately. Classic steering systems use rods and couplings to transmit the steering wheels' movements to the wheels. You might not be aware, but these couplings are not fixed, they have a small play. This adds a sort of physical "latency" to the steering, which the Cybertruck lacks. The steering motors on each axle will steer the wheels with almost zero latency (Tesla said half a millisecond).

Megacastings enter the mainstream, but not all are equal

Why do I believe this, you wonder? Because it's already happening with other Tesla tech. Take the megacastings as an example. These are large die-cast parts that replace hundreds of structural components welded together. Tesla introduced the megacastings with the Tesla Model Y, first for the rear assembly and later also for the front structure.Bizarrely, the Model 3 Highland produced at Giga Shanghai doesn't appear to use megacastings. This might change at any time, though, as Tesla also silently adopted megacastings for the Model Y in 2021. However, the Cybertruck is made with huge die-cast structures. The electric pickup has a front single-piece megacasting, while the rear assembly is made of several die-cast structures bonded together. This allowed Tesla to use smaller die-cast machines than it initially considered.

The big unknown: the unboxed vehicle manufacturing process

The magacastings have already gone mainstream, with dozens of carmakers adopting this technology. However, Tesla is not standing still, and it's already working on revamping the car manufacturing process. One of the latest advancements is the so-called unboxed vehicle manufacturing process. This brings important cost and time benefits by shortening the production line and speeding up production.In traditional manufacturing, cars are built by stamping the body parts and assembling them for painting. Later, the doors are removed to install internal components, and then added back. Tesla's unboxed vehicle system divides the process into two critical workflows. The stamped parts, including the body sides and the car's floor, are processed in one workflow. The other workflow takes care of casting the front, rear, and possibly other body parts. Later, they are all put together in the final assembly, thus eliminating some manufactuyring steps and individual components.

We first learned about the unboxed vehicle manufacturing process in March, when Tesla announced the next-generation EV platform during 2023 Investor Day. The manufacturing breakthrough should bring significant cost savings that will allow Tesla to offer a $25,000 electric vehicle. Although Tesla has not finalized the blueprints of the new manufacturing process, this will undoubtedly happen in 2024. The first place to get an unboxed vehicle manufacturing line will be Giga Texas, with Giga Mexico following later.

Li-ion battery prices will continue to drop

Li-ion battery prices were projected to fall under $100 per kWh at the pack level, but the 2020 events put a pause to this trend. The supply chain chaos that ensued caused all the prices to explode, and lithium was leading the way. Instead of trending towards price parity with ICE vehicles, electric cars became more expensive, despite the former also seeing sky-high prices.However, things finally got back on track in 2023, and next year, things will only get better. A recent BloombergNEF study showed that battery prices fell a whopping 14% in 2023 to a record low of $139/kWh. Although this is far from the $100/kWh magic threshold, things are not the same in every market. The cheapest battery cells are in China, with an average price of $126/kWh, while in the US and Europe, prices are 11% and 26% higher, respectively.

LFP battery cells gain traction, set to become dominant

As more advanced LFP cells are developed, the auto industry is more likely to use them instead of the more expensive NMC cells. LFP cells are about one-third cheaper than NMC, with the downside of being less energy-dense. However, this is changing fast, with the most advanced LFP cells from BYD and CATL claiming near parity with NCM cells in terms of energy density.Although some legacy carmakers like Ford and GM put new battery plant plans on hold, more carmakers and battery manufacturers are planning LFP cell factories in the US. Thanks to the incentives of the Inflation Reduction Act (IRA), the US market is a honeypot for battery makers. This means that more companies will enter the market, some developing their own LFP cells.

Hyundai was among the latest to announce the development of new LFP battery cells. Although they will not arrive earlier than 2025, this is just offering us a taste of what to expect from the industry leaders starting next year. Hyundai is bullish on LFP cells, claiming it can improve LFP cells' energy density to get on par with premium NMC cells.

The 4680 cells continue to disappoint; better luck next year?

While battery prices keep falling and LFP cells become better and cheaper, it's time to acknowledge that not everything is golden in the battery realm. Many promising technologies have not come to market yet, and some of them never will, being already superseded by new chemistries that weren't even on the radar a couple of years ago. Besides that, existing battery tech has not progressed as fast as many expected.Among them are Tesla's 4680 cells, now in their second generation. Tesla announced the 4680 cells during 2020 Battery Day, promising five times more energy, 16% more range, and six times more power than 2170 cells. However, the new cells are still behind the older cells in terms of energy density and charging performance. Although Tesla installed the second generation of these cells in the Cybertruck, they are still not up to snuff.

The lackluster 4680 cell performance is the reason Cybertruck was announced with a disappointing range. Instead of the promised 500-mile (805 km) mark, the tri-motor variant of the Cybertruck only goes 320 miles (515 km) on a charge. However, real-world reports from owners who already got Tesla's electric pickup show that the range is less than 300 miles (483 km). Also, charging is much slower than expected, a problem we've also seen on the 4680-cell Model Ys.

Solid-state batteries are yet to prove themselves

This was probably the single most promising battery tech that didn't pan out in 2023. However, several battery manufacturers claim they will start mass-producing solid-state battery cells in 2024. Even if this happens, the technology will take a few more years to mature, so don't expect miracles. Among the issues that need to be solved are higher costs, a high rate of mechanical failure, and the formation of dendrites, which penetrate the electrolyte and cause electrical short circuits.NIO was among the first carmakers to show a production-ready solid-state battery. The ET7 prototype traveled 649 miles (1,044 km) on a charge, with 3% of the battery energy left at the end of the trip. The solid-stated battery pack used cells developed by NIO's partner, WeLion. The 150-kWh battery pack weighed 575 kilograms (1,268 pounds), which points to an energy density of 260 Wh/kg.

The solid-state battery is the same size as NIO's liquid-electrolyte batteries currently in production, which have 100 kWh capacity at most. WeLion is confident it could start mass production in April 2024. CATL and Our Next Energy (ONE) are also working on their own solid-state battery cells, which are now in the testing phase. Both companies expect their work to become production-ready by the end of next year.

Are autonomous vehicles still a thing?

While autonomous driving failed to make the big splash that people hoped for in 2023, this doesn't mean the technology is doomed. However, it hinted that achieving self-driving might be a lot harder than imagined. Although Tesla's Full Self-Driving (Beta) software looks like the most advanced autonomous driving system, Mercedes Benz was the first to certify its Drive Pilot technology as an SAE Level-3 autonomous driving system.However, the technology is more of a proof of concept for now. Drive Pilot's many limitations mean the system can only be used on certain pre-mapped highways in Nevada and California. It can also drive semi-autonomously only in ideal weather conditions when you're traveling below 40 mph (64 kph) and only if there's a car in front to follow. The system is also unable to operate if the sun blinds the car's cameras.

Tesla is currently testing the 12th iteration of the software, which uses a single end-to-end neural network. This replaces both the city streets driving stack and the highway driving stack. It also means that Tesla is slashing more of the legacy C++ code and replacing it with neural networks. The aim is to make FSD Beta end-to-end AI, from images in, to controls out. For now, the latest FSD variant is reserved for Tesla employee vehicles, but it will go wide to customer vehicles in 2024.