Akio Toyoda is no longer the CEO of Toyota, but that did not reduce the criticism about how the Japanese automaker is dealing with electrification. It seemed that the new CEO – Koji Sato – would follow Toyoda's steps, but he created two major divisions to care for the company's future. The Hydrogen Factory and the BEV Factory are self-explanatory. However, the BEV Factory laid out its plans, showing that Toyota's strategy changed a bit.

Before Sato-san took the helm, solid-state cells would be initially used only on hybrid vehicles. Gill Pratt's explanation for that was pretty convincing. Toyota's chief scientist said that hybrids have a more demanding use, with frequent and deep charging and discharging. If the solid-state batteries did well in that test, they would excel when applied to battery electric vehicles (BEVs). It looks like the Japanese carmaker has no reserves about durability anymore.

Toyota disclosed that it achieved a breakthrough that made these cells last longer despite the rapid charging and discharging that they are expected to offer. Although it did not elaborate on that, this technological advancement seems to be the reason for the plans to change. The Japanese carmaker will have these batteries in its next generation of BEVs by 2027 or 2028. It is not clear if it will take these four to five years to validate the new cells or if it just wants to stick to the schedule it had previously established.

According to the company, the new solid-state batteries will have a greater tolerance to high voltages and temperatures. With that, they will be able to charge from 10% to 80% capacity in 10 minutes or less. A battery pack with these cells will offer 1,000 kilometers (621 miles) of range. Expect these BEVs to have similar warranty periods as those the bZ4x has. To the surprise of no one, Toyota said it will focus on reliability – for all its battery packs. Curiously, Toyota has already talked about these components in June. I'll remind you of that in a bit, not before talking about what is really new.

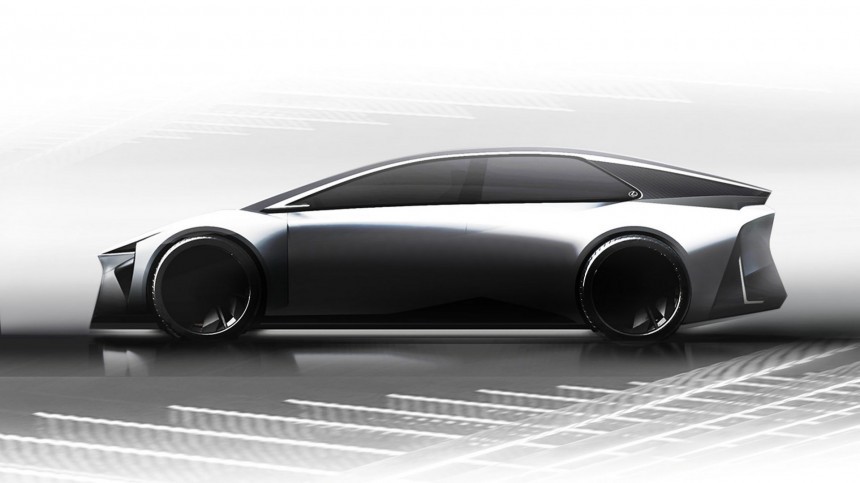

Several car companies have released electric SUVs, which have a large frontal area. Toyota is among them, as the bZ4x proves. That will apparently also change. The Japanese automaker said it will focus on aerodynamics and weight reduction. Although it did not elaborate on what it will do to make its BEVs lighter, the Japanese carmaker anticipated its battery packs will be much thinner than they currently are.

Instead of the 15 centimeters (5.9 inches) height they currently have, Toyota's future components will be 12 cm (4.7 in) tall. The company's final goal is to make a battery pack that is not higher than 10 cm (3.9 in). The Renault Mégane E-Tech and the MG4 already have components with a thickness of 11 cm (4.3 in). Ironically, the Mégane E-Tech is an SUV. The rendering Toyota released suggests it will try to sell what Volkswagen called a "flat vehicle," which is a low and long car. It may also be the case that the thinner battery pack will allow the Japanese car company to make lower SUVs.

In June, Toyota had already said that it was pursuing drag coefficients of less than 0.2 with a "new technology to reduce aerodynamic drag in any shape" developed with Mitsubishi Heavy Industries. A smaller eAxle would also allow rear passengers to sit lower. We're still waiting to hear about this technology to make any car more aerodynamic. It seems the thinner battery pack will help with these efforts.

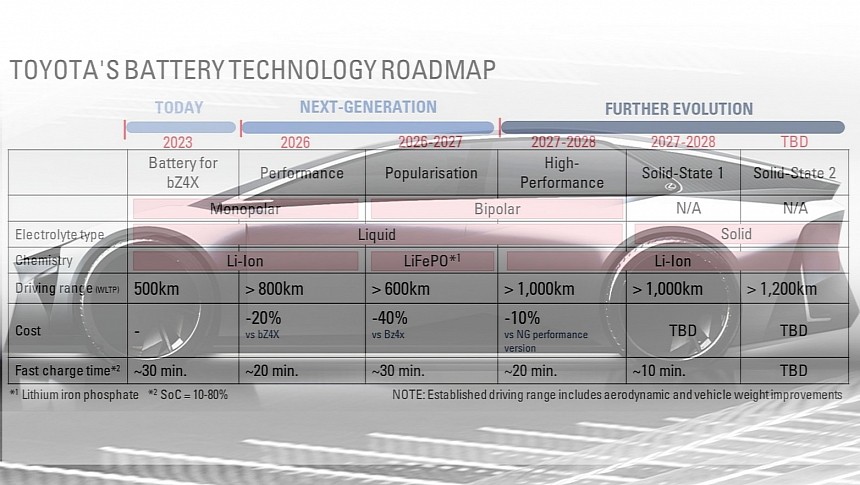

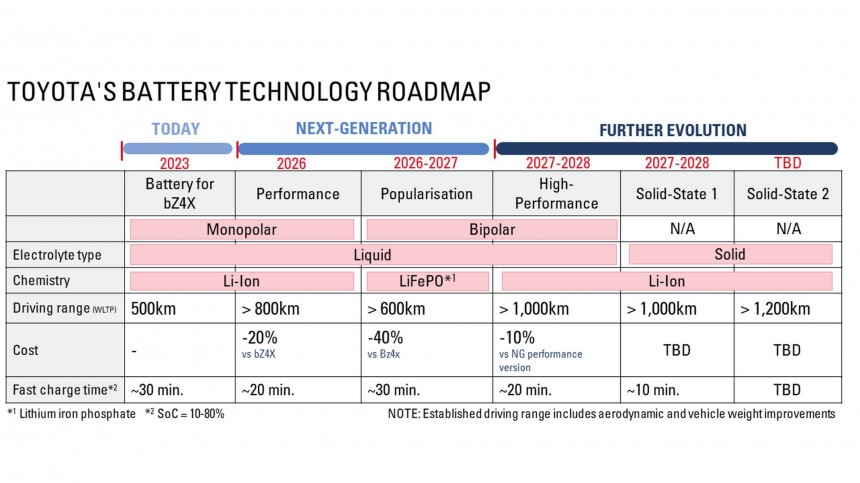

As Toyota already disclosed back then, it is developing three main battery packs. The only news about them is that they now seem to have names. Popularization will use lithium iron phosphate (LFP) cells. The automaker also refers to it as "Popularized" and promises it will have higher energy density. Another edge it will offer is the bipolar technology.

The other two are called Performance and High-Performance. Both use ternary cells (probably NMC), and the only difference is that High-Performance has more nickel in its cathodes.

Popularization will give BEVs a range that is 20% better than that of the bZ4x. If you consider the EPA range, that's 302 miles (486 kilometers) instead of 252 miles (406 km). If your reference is the WLTP cycle, the range would jump from 516 km (321 mi) to 619 km (385 mi). Performance will improve that figure to 800 km (497 miles), while High-Performance targets 1,000 km (621 miles) of range.

The still-unnamed battery packs with solid-state cells should allow the vehicles they power to run the same distances, which confirms their main advantage is reducing charging times. A second-generation solid-state battery should improve that by 20%, or to 1,200 km (746 miles). These BEVs should use large castings, just like Tesla does with the Model Y and should do with the Cybertruck.

Toyota disclosed that it achieved a breakthrough that made these cells last longer despite the rapid charging and discharging that they are expected to offer. Although it did not elaborate on that, this technological advancement seems to be the reason for the plans to change. The Japanese carmaker will have these batteries in its next generation of BEVs by 2027 or 2028. It is not clear if it will take these four to five years to validate the new cells or if it just wants to stick to the schedule it had previously established.

According to the company, the new solid-state batteries will have a greater tolerance to high voltages and temperatures. With that, they will be able to charge from 10% to 80% capacity in 10 minutes or less. A battery pack with these cells will offer 1,000 kilometers (621 miles) of range. Expect these BEVs to have similar warranty periods as those the bZ4x has. To the surprise of no one, Toyota said it will focus on reliability – for all its battery packs. Curiously, Toyota has already talked about these components in June. I'll remind you of that in a bit, not before talking about what is really new.

Instead of the 15 centimeters (5.9 inches) height they currently have, Toyota's future components will be 12 cm (4.7 in) tall. The company's final goal is to make a battery pack that is not higher than 10 cm (3.9 in). The Renault Mégane E-Tech and the MG4 already have components with a thickness of 11 cm (4.3 in). Ironically, the Mégane E-Tech is an SUV. The rendering Toyota released suggests it will try to sell what Volkswagen called a "flat vehicle," which is a low and long car. It may also be the case that the thinner battery pack will allow the Japanese car company to make lower SUVs.

In June, Toyota had already said that it was pursuing drag coefficients of less than 0.2 with a "new technology to reduce aerodynamic drag in any shape" developed with Mitsubishi Heavy Industries. A smaller eAxle would also allow rear passengers to sit lower. We're still waiting to hear about this technology to make any car more aerodynamic. It seems the thinner battery pack will help with these efforts.

The other two are called Performance and High-Performance. Both use ternary cells (probably NMC), and the only difference is that High-Performance has more nickel in its cathodes.

Popularization will give BEVs a range that is 20% better than that of the bZ4x. If you consider the EPA range, that's 302 miles (486 kilometers) instead of 252 miles (406 km). If your reference is the WLTP cycle, the range would jump from 516 km (321 mi) to 619 km (385 mi). Performance will improve that figure to 800 km (497 miles), while High-Performance targets 1,000 km (621 miles) of range.

The still-unnamed battery packs with solid-state cells should allow the vehicles they power to run the same distances, which confirms their main advantage is reducing charging times. A second-generation solid-state battery should improve that by 20%, or to 1,200 km (746 miles). These BEVs should use large castings, just like Tesla does with the Model Y and should do with the Cybertruck.