Tesla Cybertruck revolutionized the automotive industry with a groundbreaking 48-volt electrical system and a steer-by-wire system. These advances would not have been possible without a new approach to vehicular wiring and communications, which the EV maker recently filed to patent.

Although the Cybertruck's specifications might seem underwhelming, this only appears so because Elon Musk exaggerated its qualities over the years. One area that did not disappoint, though, was its advanced technologies. We knew Tesla would shoot for the stars, but even so, there are things that many people never expected.

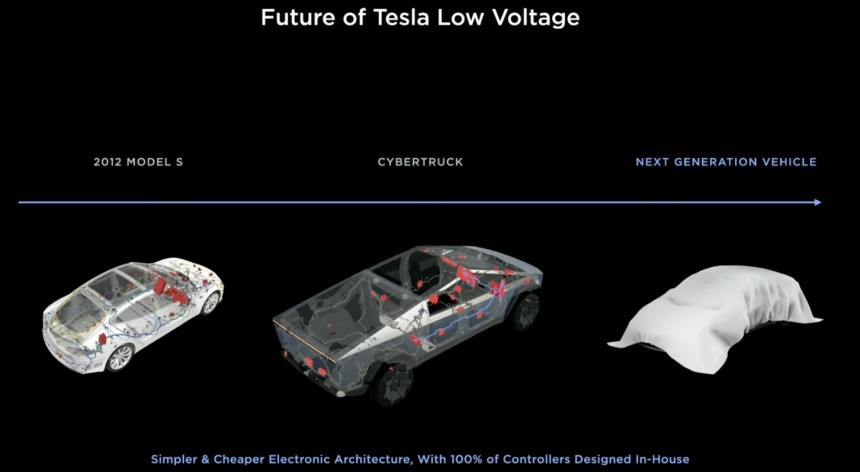

One such thing was the 48-volt low-voltage electrical system used for the first time on a production vehicle. But Tesla went way further by improving and simplifying the electrical architecture, a critical achievement that will allow it to build the next-generation EVs at cost.

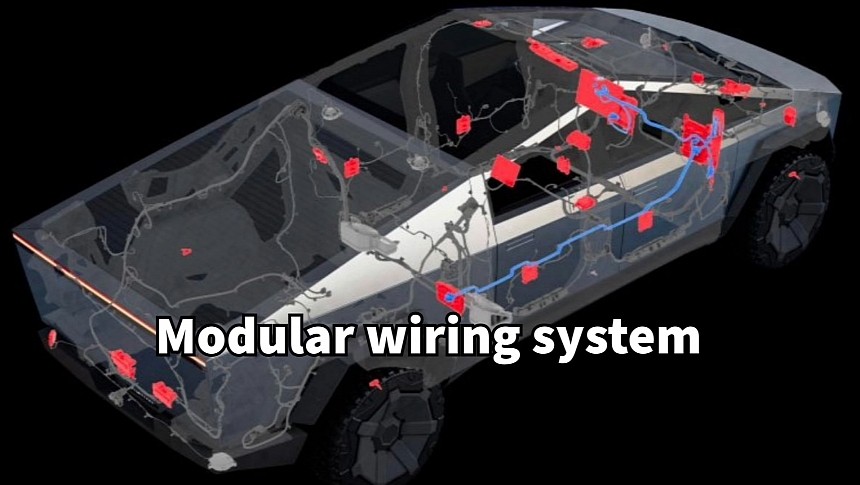

Tesla announced that the Cybertruck would have a significantly simplified wiring architecture compared to previous Tesla EVs. Tesla achieved this by using several local controllers connected to a high-speed communications bus instead of connecting every electrical component to a central controller. To understand how groundbreaking this is, it's worth talking about legacy vehicles.

Typically, every sensor and electrical component on a vehicle must be connected to the central controller and the low-voltage system for power. Sometimes, this means many wires for complex parts. Let's take the door as an example. It might comprise sensors to signal the car's computers whether it is open, closed, or at an angle. This is also true for the windows, which feature buttons to trigger opening and closing. The switches are connected to the vehicle's controller, which in turn is connected to the window actuators to lower or raise the glass.

Add the speakers into the equation, and you understand why wiring harnesses are such a mess. Wires spread for miles inside a modern vehicle, adding complexity, costs, and weight. Worse than that, building and installing them is done by hand. These are expensive and time-consuming processes, which Tesla wanted to eliminate. This is why it came up with the idea of distributed controllers. Instead of a central unit, the vehicle would have many local controllers for various functions.

The electric pickup features a steer-by-wire system that needs a high-speed (low-latency) communication bus to transmit the steering wheel movements to the Cybertruck's wheels in real-time. That's why the CAN bus that most cars use today was found inadequate: it has a low data throughput (about 1 Mbps) and high latency. Instead, Tesla used a version of the Gigabit Ethernet architecture with Power over Ethernet to power the components using the same data wires.

Tesla's data network used in the Cybertruck has a latency of only half a millisecond, which is perfect for steering signals. It also provides enough bandwidth to allow various controllers to communicate in real-time, working as one. Tesla patented this communication system last December, and the Cybertruck puts it to good use. However, Tesla has another ace up its sleeves that helps simplify manufacturing. This is essential for the upcoming $25,000 EV that Tesla plans to launch in 2025.

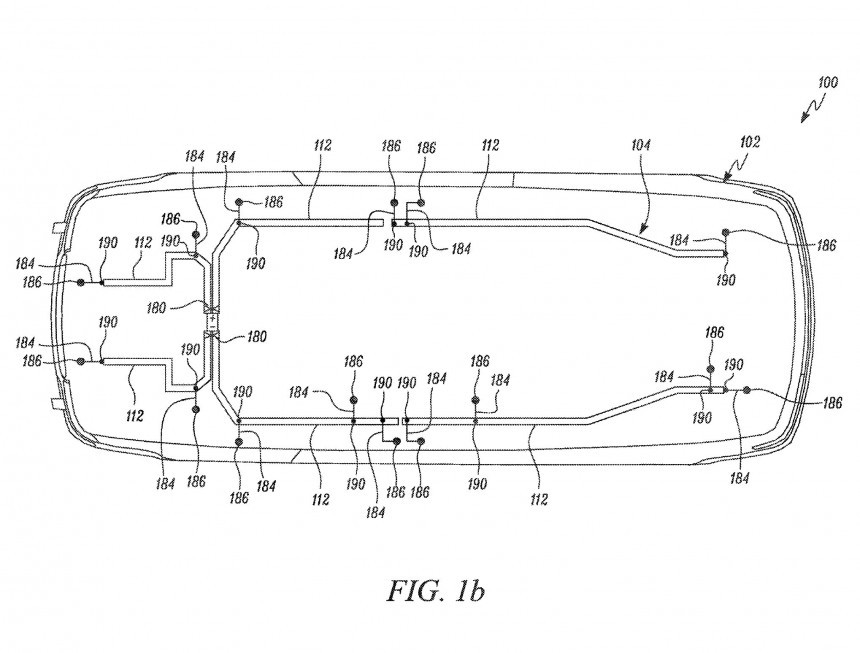

Based on the graphics included with the patent filing, the modular wiring system will make cables obsolete, and components will click into place thanks to the proprietary connectors. It's also flat, so the wires would not protrude or even be noticeable. Unlike wiring harnesses, which need to be installed manually by workers on the production line, the modular wiring system installation doesn't need a dedicated step in the manufacturing process.

Instead, the flat wiring system's connectors are included with every car component, from structural panels to more complex assemblies, such as the doors. Installing these components will also involve establishing the necessary connections, similar to how Lego pieces bond together. This reduces the production time and costs.

I'm not sure the Cybertruck includes this type of wiring, although it certainly uses the automotive-grade Gigabit Ethernet bus instead of a CAN bus. However, the two systems work seamlessly together, and the benefits are two-fold when used together. The low-cost model Tesla plans might not use steer-by-wire or other fancy components, but it will surely need a fast communication backbone and a modular wiring system like the one described in the patent below.

One such thing was the 48-volt low-voltage electrical system used for the first time on a production vehicle. But Tesla went way further by improving and simplifying the electrical architecture, a critical achievement that will allow it to build the next-generation EVs at cost.

Tesla announced that the Cybertruck would have a significantly simplified wiring architecture compared to previous Tesla EVs. Tesla achieved this by using several local controllers connected to a high-speed communications bus instead of connecting every electrical component to a central controller. To understand how groundbreaking this is, it's worth talking about legacy vehicles.

Add the speakers into the equation, and you understand why wiring harnesses are such a mess. Wires spread for miles inside a modern vehicle, adding complexity, costs, and weight. Worse than that, building and installing them is done by hand. These are expensive and time-consuming processes, which Tesla wanted to eliminate. This is why it came up with the idea of distributed controllers. Instead of a central unit, the vehicle would have many local controllers for various functions.

Distributed controllers

For instance, a door controller would be responsible for the window, speakers, lights, mirror, and other door components that need electrical input to work. The wires, in this case, will be short and all contained inside the door assembly. The door will then be connected to the vehicle's data bus with only two wires, which also provide power to the electrical components. Only two wires for all the door's complex functions, versus more than a dozen in a legacy car, this is what Tesla has done with the Cybertruck.The electric pickup features a steer-by-wire system that needs a high-speed (low-latency) communication bus to transmit the steering wheel movements to the Cybertruck's wheels in real-time. That's why the CAN bus that most cars use today was found inadequate: it has a low data throughput (about 1 Mbps) and high latency. Instead, Tesla used a version of the Gigabit Ethernet architecture with Power over Ethernet to power the components using the same data wires.

Tesla's data network used in the Cybertruck has a latency of only half a millisecond, which is perfect for steering signals. It also provides enough bandwidth to allow various controllers to communicate in real-time, working as one. Tesla patented this communication system last December, and the Cybertruck puts it to good use. However, Tesla has another ace up its sleeves that helps simplify manufacturing. This is essential for the upcoming $25,000 EV that Tesla plans to launch in 2025.

Modular wiring system

According to a recent patent filing titled "Wiring System Architecture," Tesla designed a modular wiring system that would vastly simplify manufacturing. This comprises backbone wiring for power and data, being EMI-shielded to limit interferences. The best part is that this modular wiring includes conductive paint and adhesives on the car's body, and it supports robotic assembly and Tesla's new unboxed vehicle manufacturing process.Instead, the flat wiring system's connectors are included with every car component, from structural panels to more complex assemblies, such as the doors. Installing these components will also involve establishing the necessary connections, similar to how Lego pieces bond together. This reduces the production time and costs.

I'm not sure the Cybertruck includes this type of wiring, although it certainly uses the automotive-grade Gigabit Ethernet bus instead of a CAN bus. However, the two systems work seamlessly together, and the benefits are two-fold when used together. The low-cost model Tesla plans might not use steer-by-wire or other fancy components, but it will surely need a fast communication backbone and a modular wiring system like the one described in the patent below.