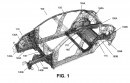

Tesla entered a new era with the start of production at Giga Texas, having transitioned to a revolutionary fabrication process. The Model Y built in Austin features single-piece front and rear megacastings, as well as a structural battery pack with 4680 cells. This fabrication process would soon be extended to other gigafactories, starting with Giga Berlin.

The new manufacturing technologies would reach other Tesla factories as a separate production line added to the existing facilities. In time, all Tesla production would be transitioned to the new revolutionary design. But first, the revolution will get to Giga Berlin, where Tesla has already started experimenting with the megacastings and structural battery packs.

According to Drive Tesla, citing sources familiar with the project, a secondary production line has been established in Gruenheide to test the new manufacturing process. Only three test vehicles were built on the new line to prove that Giga Berlin is ready to embrace the future. None of them is drivable, though, as they were assembled just for testing the machines and the assembly line.

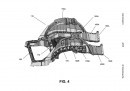

Tesla Model Y test cars were built with single-piece die-cast structures front and rear. Since no Giga Press machines were installed at Giga Berlin to create the front castings, they must have been shipped from Giga Texas. The same goes for the 4680 cells, but instead of bringing them from Texas, Tesla opted to use dummy cells to fill the structural battery packs. This essentially made the crossovers undrivable, but this is not the point. They can still be used for internal testing and crash tests.

With the test builds successful, Tesla can move on with implementing the new manufacturing process. To do that, the EV maker must install the necessary Giga Presses and complete the battery factory on the grounds of Giga Berlin. This is not expected to come online before the year’s end, so Giga Texas remains the only manufacturing place for the 4680 cells. Of course, some 4680 cells are also built in Fremont, but Tesla has there only a battery research center rather than a full-fledged battery production line.

According to Drive Tesla, citing sources familiar with the project, a secondary production line has been established in Gruenheide to test the new manufacturing process. Only three test vehicles were built on the new line to prove that Giga Berlin is ready to embrace the future. None of them is drivable, though, as they were assembled just for testing the machines and the assembly line.

Tesla Model Y test cars were built with single-piece die-cast structures front and rear. Since no Giga Press machines were installed at Giga Berlin to create the front castings, they must have been shipped from Giga Texas. The same goes for the 4680 cells, but instead of bringing them from Texas, Tesla opted to use dummy cells to fill the structural battery packs. This essentially made the crossovers undrivable, but this is not the point. They can still be used for internal testing and crash tests.

With the test builds successful, Tesla can move on with implementing the new manufacturing process. To do that, the EV maker must install the necessary Giga Presses and complete the battery factory on the grounds of Giga Berlin. This is not expected to come online before the year’s end, so Giga Texas remains the only manufacturing place for the 4680 cells. Of course, some 4680 cells are also built in Fremont, but Tesla has there only a battery research center rather than a full-fledged battery production line.