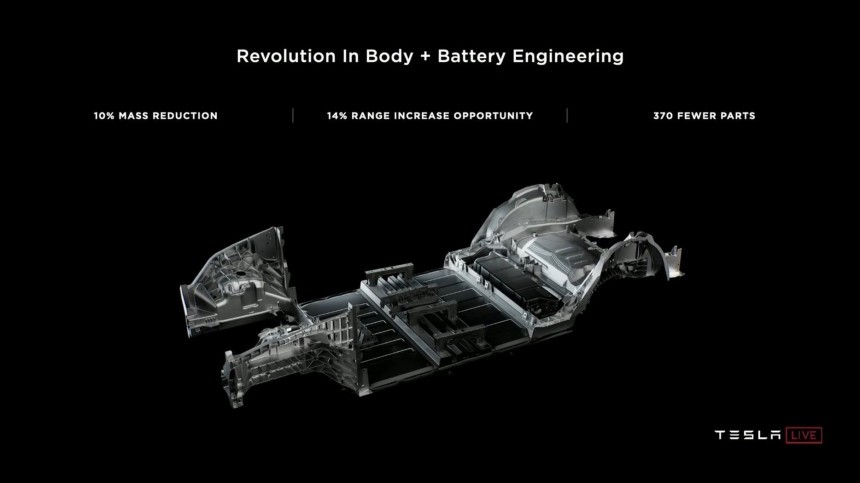

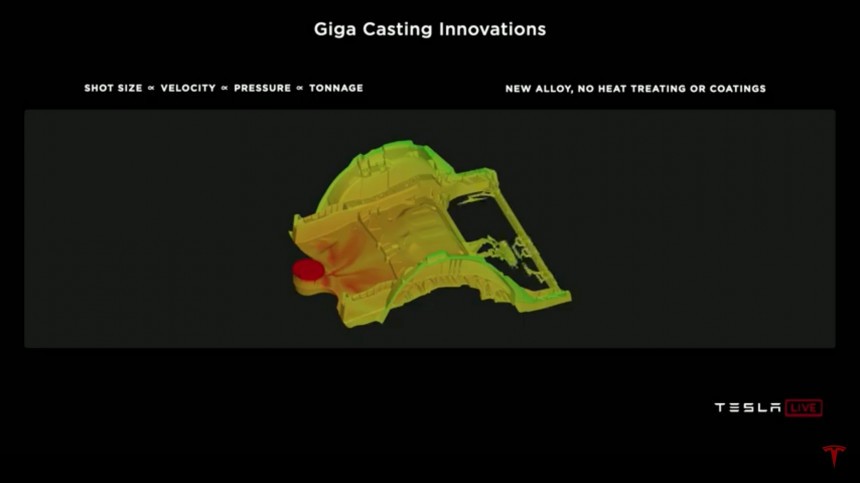

The mega castings were apparently a great idea. Instead of welding multiple stamped parts to form the rear or front structures of the car, Tesla would just cast these massive structures in one piece. It bought multiple IDRA Group Giga Presses, developed a special alloy, and started delivering the Model Y with them. However, it was not all of a sudden.

The Model Y started its career with two mega castings for the rear structure in Fremont. Tesla later managed to make casting for it and it would be on the verge of doing the front structure in the same way. For that arrangement to work as planned, the structural battery pack would be crucial. Otherwise, the stamped body would still have to be stiff enough to dismiss the structural component that would link the front and rear mega castings.

Tesla presented a 2170 battery pack right beside the 4680 battery pack at Giga Grünheide’s party. Although that looked just like the comparison of the current and the future Model Y, the 2170 unit looked different from the one currently used, according to Tesla fans. Alex Voigt said it appeared not to have modules anymore, although the picture he shared presented four clear divisions. Scott Schreck pointed that out in his tweet.

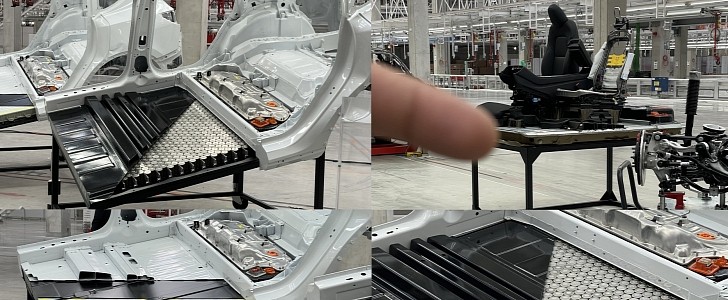

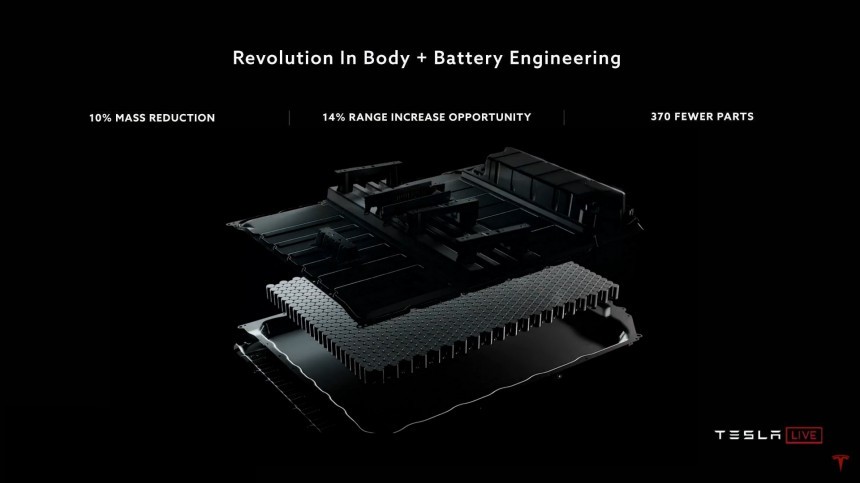

Adam Berg then showed that the 4680 battery pack will have the front seats directly mounted to it. The body-in-white would then be placed above them – like a hat – which would save the need for robots to place the seats inside the car. Tesla will still have to use them for the instrument panel and the rear seat, but the solution for the front units could help to speed up manufacturing. This is what reinforces the idea of a structural 2170 battery pack.

More than that, if the German Model Y units were conceived to present a structural battery pack, not having it would demand Tesla to produce a different Model Y, with a body that was already strong enough without the structural component. Unless the vehicle was conceived to work with and without the internal elements to ensure that, it is almost equivalent to producing two different cars in the same production line. Theoretically, It would be easier to create a structural battery pack with the 2170 cells.

That’s something not even the people invited for the Giga Fest were able to determine. That indicates that Tesla’s decision to kill its PR department may have made it more difficult to talk even with its most devoted fans.

Confirming other rumors, Musk also asked people to apply from all over Europe to work at Giga Grünheide. The company is facing difficulties in recruiting workers in Germany. It may have to do with its anti-union approach and to offering lower wages than other companies. The pay gap would be compensated by the promise of stock options and bonuses. However, it seems it did not attract people as much as Tesla thought it would.

Apart from the fans, what the factory attracted were about 250 protesters that screamed that Tesla was stealing their water. Musk laughed about these concerns in a previous visit to the factory in August, saying that it rains a lot in the area.

Met with Ralf Brandstätter & our top managers in Wolfsburg to kickoff the race against Tesla in Grünheide. We‘re ready! Trinity will revolutionize Wolfsburg. pic.twitter.com/mcpu3JyLQJ

— Herbert Diess (@Herbert_Diess) October 1, 2021

It appears the 2170 packs don't have modules anymore?

— Alex (@alex_avoigt) October 9, 2021

That alone would be a huge improvement pic.twitter.com/xVTBnxyE45

Seats will be mounted directly onto the 4680 pack(!). Then chassis is lifted on top of it. No more robots arms through the door openings. #Tesla #GigaBerlin pic.twitter.com/IMfW6exOnK

— Adam Berg (@AdamBerg4680) October 9, 2021

@LimitingThe doesn’t it still look like there are modules in the 2170 pack? The visible area still appears divided vs what the 4680 pack looks like. pic.twitter.com/u4jz9MoMWC

— Scott Schreck (@ScottSchreck2) October 9, 2021

2170 cells pic.twitter.com/YCrbLtZz6u

— Paul Kelly ???????? (@shortword) October 9, 2021