Panasonic, Tesla's first battery partner, announced it will delay 4680 cell production until April-September 2024. The official reason was that it needed more time to improve battery performance. It was another way of saying the new cells were not ready.

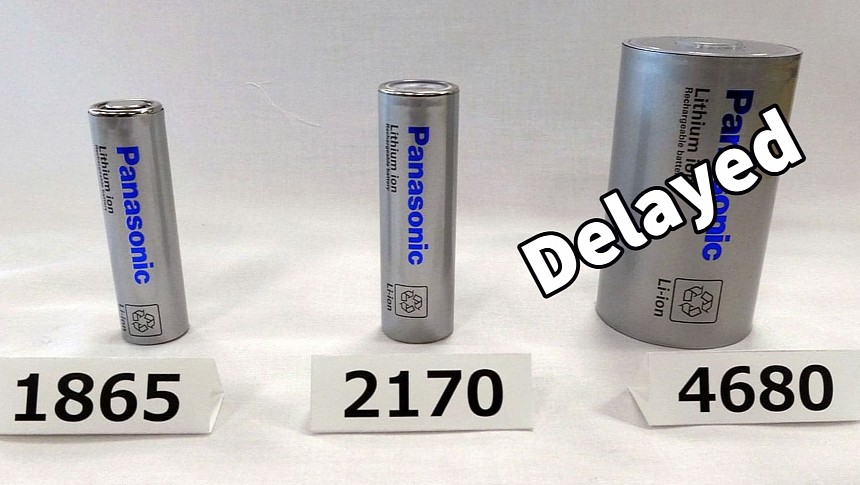

Tesla introduced the 4680 battery cell format in 2020 at the Battery Day event, promising lower manufacturing costs and higher energy density than the regular 2170 cells. For those that did not follow Tesla recently, the 4680 cells were supposed to offer improved chemistry, besides the bigger form factor. Also, Tesla is trying to crack the dry-electrode manufacturing process, which would provide substantial cost benefits. Still, a recent teardown showed that the chemistry remained essentially unchanged compared to the 2170 cells.

The 4680 cells are still in limited production three years after being announced. Tesla has tried to convince its partners to accelerate the development of the 4680 battery cells. Panasonic, Tesla's first battery partner, is among the manufacturers working to bring the 4680 cells into mass production. Still, things don't appear to be advancing faster at the Japanese manufacturer than at Tesla.

Panasonic announced on Wednesday that it will delay the commercial production of the 4680 battery cells for Tesla. Initial plans indicated that mass production of the new cells would begin between April 2023 and March 2024, representing the fiscal year 2024 in Japan. The new horizon has been pushed back to April-September 2024, 6 to 12 months later than initially estimated. The official reason Panasonic offered for the delay was the need to introduce "performance-improvement measures."

While the wording sounds positive, it also implies that Panasonic is still far from being competitive with the 4680 cells it currently produces. It certainly needs more time to refine the technology before shipping the cells to Tesla. Panasonic operates a pilot 4680 production line in Japan, but it has to compete with Tesla, which already produces its own 4680 cells. Understandably, Panasonic cannot sell its cells to Tesla unless they are on par or superior to those produced in-house by the EV maker.

The delay means that Panasonic will not produce 4680 cells at its new manufacturing facility in Kansas. The factory construction began in November 2022, and the production is planned to start sometime between April 2024 and March 2025. The factory has an initial production capacity of 30 GWh per year and will produce 2170 cells, at least in the first phase.

While Panasonic is probably working on 4680 cells using the traditional wet manufacturing process, Tesla is making strides with the dry-electrode process. The EV maker makes the new cells at its experimental production facility in Fremont and plans to build a new production line at Giga Texas to support the Cybertruck production. The Model Y AWD made at Giga Texas is currently built with 4680 cells, but it doesn't seem to offer notable advantages compared to the Model Y LR, which uses 2170 cells.

The 4680 cells are still in limited production three years after being announced. Tesla has tried to convince its partners to accelerate the development of the 4680 battery cells. Panasonic, Tesla's first battery partner, is among the manufacturers working to bring the 4680 cells into mass production. Still, things don't appear to be advancing faster at the Japanese manufacturer than at Tesla.

Panasonic announced on Wednesday that it will delay the commercial production of the 4680 battery cells for Tesla. Initial plans indicated that mass production of the new cells would begin between April 2023 and March 2024, representing the fiscal year 2024 in Japan. The new horizon has been pushed back to April-September 2024, 6 to 12 months later than initially estimated. The official reason Panasonic offered for the delay was the need to introduce "performance-improvement measures."

While the wording sounds positive, it also implies that Panasonic is still far from being competitive with the 4680 cells it currently produces. It certainly needs more time to refine the technology before shipping the cells to Tesla. Panasonic operates a pilot 4680 production line in Japan, but it has to compete with Tesla, which already produces its own 4680 cells. Understandably, Panasonic cannot sell its cells to Tesla unless they are on par or superior to those produced in-house by the EV maker.

The delay means that Panasonic will not produce 4680 cells at its new manufacturing facility in Kansas. The factory construction began in November 2022, and the production is planned to start sometime between April 2024 and March 2025. The factory has an initial production capacity of 30 GWh per year and will produce 2170 cells, at least in the first phase.

While Panasonic is probably working on 4680 cells using the traditional wet manufacturing process, Tesla is making strides with the dry-electrode process. The EV maker makes the new cells at its experimental production facility in Fremont and plans to build a new production line at Giga Texas to support the Cybertruck production. The Model Y AWD made at Giga Texas is currently built with 4680 cells, but it doesn't seem to offer notable advantages compared to the Model Y LR, which uses 2170 cells.