The last time I spoke about Neocarbonix, the solution Nanoramic had developed to create composite electrodes was supposed to reach the market in 2023. So far, it has received a $3.6-million contract and a strategic investment from GM Ventures to eventually apply Neocarbonix in Ultium cells. Still, it is yet to be seen in production batteries. That should get easier when E-Lyte delivers a tailor-made electrolyte for Neocarbonix, which promises to be remarkable in itself. Allow me to explain why.

Batteries have their electrodes manufactured by wet coating with polymer binders and solvents that are highly toxic, such as N-Methyl-2-pyrrolidone (NMP). Even the polymers are not that safe. Per- and polyfluoroalkyl (PFAS) substances are under surveillance by the European Chemical Agency (ECHA) and the US Environmental Protection Agency (EPA) and may have their use restricted. Batteries also apply polyvinylidene fluoride (PVDF) as binders for electrodes. This is a conversation battery electric vehicle (BEV) advocates will always try to dodge, apart from how necessary it will be to eventually replace the battery packs.

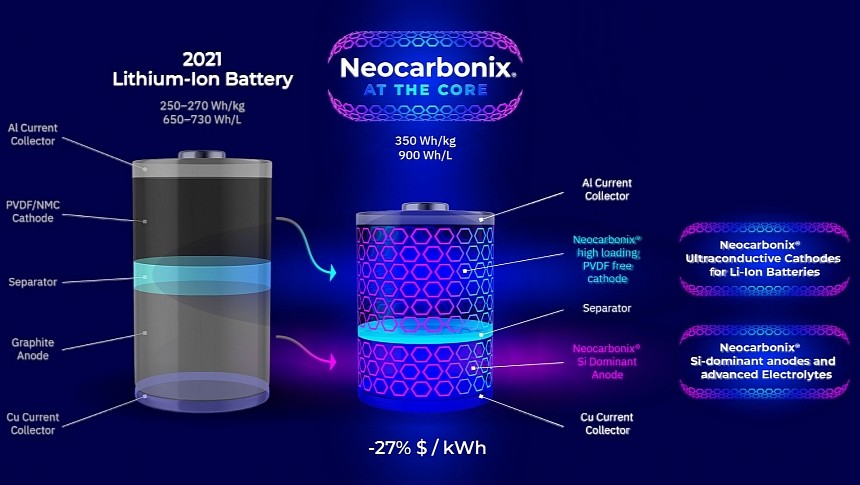

Neocarbonix allegedly does not need any of these substances to create electrodes and batteries with higher energy density. It delivers a carbon structure in electrodes that contains nanotubes, which increase conductivity and makes it easier for the ions to travel from the cathode to the anode and back.

According to Nanoramic, a battery using electrodes made with Neocarbonix can be up to 30% more energy-dense than those using polymer binders. In a 2170 cell, that represents going from around 270 Wh/kg to 350 Wh/kg. The company claims it can also charge or discharge two times faster than a conventional one, which is an advantage that battery makers would kill to offer in their products. Charging times are a massive issue in BEV adoption.

Nanoramic also said Neocarbonix's thermal properties prevent it from aging and breaking like those electrodes with polymer binders do. In other words, it also promises to last longer and cost less. NMP, PVDF, and PFAS are expensive to deal with, especially in the drying phase of wet coating: toxic elements like NMP have to be recovered.

As it only works with environmentally-friendly solvents, Neocarbonix wet coating process is much cheaper than conventional ones. Nanoramic also defends that it is much better than dry coating because it "creates porous electrode structures with large surface areas, which is critical to improving battery performance." The company also stressed that the dry coating advantages Tesla promised its 4680 cells would have – and didn't deliver – included the danger of dust explosions due to the use of fine dry powders.

Nanoramic never spoke about that, but Neocarbonix probably increases energy density in one of these two ways: either it reduces the quantity of inactive material in the cells, or it allows them to improve their active material percentage. It may be the case that it delivers a bit of both. With ternary cells, that only gets them closer to their theoretical energy density limits. Developing a cell with a much higher energy density would depend on other chemistries, such as lithium-sulfur (Li-S). Curiously, the battery startup Theion said it had achieved amazing advancements with this chemistry by using carbon nanotubes – the same technology Nanoramic employs.

The $3.6-million contract the company won came from the United States Advanced Battery Consortium LLC (USABC) in collaboration with the US Department of Energy (DOE). The purpose of that agreement is for Nanoramic to develop a low-cost/fast-charge (LCFC) Li-ion battery. Considering the amount of money involved, it is not enough for Nanoramic to become a battery manufacturer. That said, it will probably develop the project for USABC and DOE, and they will find a way to make the resulting LCFC. Commisioning it to a battery manufacturer looks like the most likely development, but God knows how long that will take.

We'll probably have to wait for GM to unveil the Ultium cell that will use this technology to see a production battery with Neocarbonix. As General Motors has a partnership with LG Energy Solution (LGES) for these cells, the South Korean company should be the first battery maker to adopt the carbon-structure electrodes Nanoramic conceived unless the company has other partnerships we have not heard about so far. If you think it through, it is strange that nobody employed it so far with so many alleged advantages. The company states Neocarbonix can be used with any chemistry, including lithium iron phosphate (LFP).

It is not clear which advantages the new E-Lyte electrolyte can offer to a battery that adopts Neocarbonix. As the companies have just announced their partnership and the beginning of their work together, it is possible that they also do not know the impacts a tailor-made electrolyte can have in any production cell that adopts both solutions. The targets are evident, though: extending battery life and improving performance. The question is whether E-Lyte can deliver that compared to ordinary electrolytes, particularly in something that can work with any chemistry.

Neocarbonix allegedly does not need any of these substances to create electrodes and batteries with higher energy density. It delivers a carbon structure in electrodes that contains nanotubes, which increase conductivity and makes it easier for the ions to travel from the cathode to the anode and back.

According to Nanoramic, a battery using electrodes made with Neocarbonix can be up to 30% more energy-dense than those using polymer binders. In a 2170 cell, that represents going from around 270 Wh/kg to 350 Wh/kg. The company claims it can also charge or discharge two times faster than a conventional one, which is an advantage that battery makers would kill to offer in their products. Charging times are a massive issue in BEV adoption.

As it only works with environmentally-friendly solvents, Neocarbonix wet coating process is much cheaper than conventional ones. Nanoramic also defends that it is much better than dry coating because it "creates porous electrode structures with large surface areas, which is critical to improving battery performance." The company also stressed that the dry coating advantages Tesla promised its 4680 cells would have – and didn't deliver – included the danger of dust explosions due to the use of fine dry powders.

Nanoramic never spoke about that, but Neocarbonix probably increases energy density in one of these two ways: either it reduces the quantity of inactive material in the cells, or it allows them to improve their active material percentage. It may be the case that it delivers a bit of both. With ternary cells, that only gets them closer to their theoretical energy density limits. Developing a cell with a much higher energy density would depend on other chemistries, such as lithium-sulfur (Li-S). Curiously, the battery startup Theion said it had achieved amazing advancements with this chemistry by using carbon nanotubes – the same technology Nanoramic employs.

We'll probably have to wait for GM to unveil the Ultium cell that will use this technology to see a production battery with Neocarbonix. As General Motors has a partnership with LG Energy Solution (LGES) for these cells, the South Korean company should be the first battery maker to adopt the carbon-structure electrodes Nanoramic conceived unless the company has other partnerships we have not heard about so far. If you think it through, it is strange that nobody employed it so far with so many alleged advantages. The company states Neocarbonix can be used with any chemistry, including lithium iron phosphate (LFP).

It is not clear which advantages the new E-Lyte electrolyte can offer to a battery that adopts Neocarbonix. As the companies have just announced their partnership and the beginning of their work together, it is possible that they also do not know the impacts a tailor-made electrolyte can have in any production cell that adopts both solutions. The targets are evident, though: extending battery life and improving performance. The question is whether E-Lyte can deliver that compared to ordinary electrolytes, particularly in something that can work with any chemistry.