The EV industry is currently making its mark on the consumer market, but perhaps it has even more potential in the commercial transportation industry. Most commercial urban traffic is done through vans and medium-sized trucks; they are constantly on the move to deliver all sorts of goods. That's where vehicle electrification might have a notable impact, as it contributes to better air quality, reduces noise pollution, and is locally emission-free.

Companies are trying to innovate and find more sustainable and environmentally friendly ways to develop electric motors. One such example is Bosch – it is now starting volume production of a new drive unit destined for light commercial vehicles.

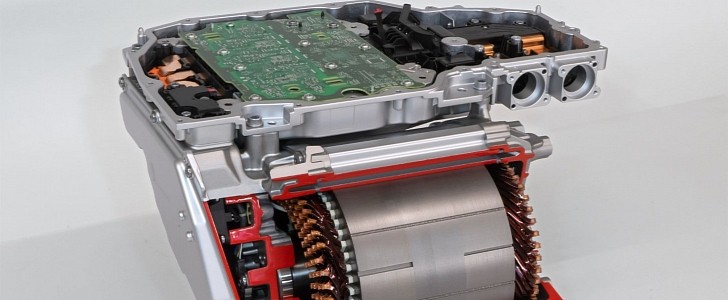

The drive unit consists of an electric motor and an integrated inverter. The inverter controls the motor and connects it to the high-voltage battery. Together, they weigh around 80 kg (176 lbs.).

The company has managed to speed up the development phase and cut some costs by basing the design of the motor and inverter on the technology used in passenger cars. A single-speed transmission can be used because of the high rotational speed of the motor, and new microcontrollers significantly increase the motor's computing power, so complex control algorithms can be processed extremely fast. The module is mainly software-dependent and can be altered to meet specific customer requirements.

Dr. Markus Heyn, member of the Bosch board of management and chairman of the Mobility Solutions business sector, said, "Bosch is driving forward e-mobility also in commercial vehicles. Compared to its predecessors, the new unit provides even higher power and torque density and is even lighter and more compact".

The company has decreased losses by more than 20% in the new drive unit by using new semiconductors. The inverter now has a 97% efficiency level, which allows the vehicle's range to increase. Due to the flexible construction, the drive module can be integrated into both new and existing models.

The customer Daimler Truck will showcase the Bosch electric drive, supplemented by the vehicle control unit and a DC/DC converter. It can supply an output of 129 kW, a continuous power of 100 kW, and a peak torque of 430 Nm (317 feet-pounds). This performance can ensure proper driving capabilities even for heavier vehicles in hilly cities.

The drive module will be produced at the Bosch lead plant for electric drives in Hildesheim, Germany.

The drive unit consists of an electric motor and an integrated inverter. The inverter controls the motor and connects it to the high-voltage battery. Together, they weigh around 80 kg (176 lbs.).

The company has managed to speed up the development phase and cut some costs by basing the design of the motor and inverter on the technology used in passenger cars. A single-speed transmission can be used because of the high rotational speed of the motor, and new microcontrollers significantly increase the motor's computing power, so complex control algorithms can be processed extremely fast. The module is mainly software-dependent and can be altered to meet specific customer requirements.

Dr. Markus Heyn, member of the Bosch board of management and chairman of the Mobility Solutions business sector, said, "Bosch is driving forward e-mobility also in commercial vehicles. Compared to its predecessors, the new unit provides even higher power and torque density and is even lighter and more compact".

The company has decreased losses by more than 20% in the new drive unit by using new semiconductors. The inverter now has a 97% efficiency level, which allows the vehicle's range to increase. Due to the flexible construction, the drive module can be integrated into both new and existing models.

The customer Daimler Truck will showcase the Bosch electric drive, supplemented by the vehicle control unit and a DC/DC converter. It can supply an output of 129 kW, a continuous power of 100 kW, and a peak torque of 430 Nm (317 feet-pounds). This performance can ensure proper driving capabilities even for heavier vehicles in hilly cities.

The drive module will be produced at the Bosch lead plant for electric drives in Hildesheim, Germany.