We are all witnessing an unprecedented growth of the aerospace industry and an important part of that is rocket engine development, meant to increase efficiency while cutting costs. One of these innovative projects comes from Europe and promises to boost rocket performance by 15%.

According to the German Aerospace Center (DLR), the global space market is not only growing at a rapid pace, but it’s also more diverse than ever. In addition to more complex projects, like the European Ariane launcher, microlaunchers are also on the rise.

As more models are being developed, the bar is also raised in terms of performance. Next-generation launchers are expected to carry increasingly heavier loads and for that they require efficient engines.

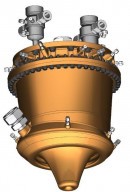

DLR is testing a new space propulsion system in collaboration with Spanish start-up Pangea Aerospace. Starting from October 2021, DLR will begin testing an innovative aerospike engine at one of its large-scale facilities, the European research and technology test stand P8. By using multiple demonstrators developed by Pangea Aerospace, DLR will carry out complex functional tests, known as hot-fire tests, for this next-generation engine.

The aerospike engine concept is not new in itself and it’s been researched over past decades. However, it’s the first time when innovative materials and advanced technology are available for bringing this concept to life. This particular material is called GRCop42 and it’s a powder copper alloy.

Pangea Aerospace owns the exclusive capabilities for developing this material in Europe. Meant for developing rocket engine combustion chambers, the GRCop42 was also adapted by NASA for additive manufacturing.

Additive manufacturing, commonly known as 3D printing, is one of the techniques that’s taking center stage at the moment. Rapid manufacturing, reusability, lower costs and increased performance are the main advantages of 3D printing, combined with the innovative materials.

According to Pangea, this will be the world’s first copper aerospike engine that’s 3D-printed. DLR will conduct engine tests for this innovative propulsion technology at its Lampoldshausen site, a facility with unique testing infrastructure in Europe.

As more models are being developed, the bar is also raised in terms of performance. Next-generation launchers are expected to carry increasingly heavier loads and for that they require efficient engines.

DLR is testing a new space propulsion system in collaboration with Spanish start-up Pangea Aerospace. Starting from October 2021, DLR will begin testing an innovative aerospike engine at one of its large-scale facilities, the European research and technology test stand P8. By using multiple demonstrators developed by Pangea Aerospace, DLR will carry out complex functional tests, known as hot-fire tests, for this next-generation engine.

The aerospike engine concept is not new in itself and it’s been researched over past decades. However, it’s the first time when innovative materials and advanced technology are available for bringing this concept to life. This particular material is called GRCop42 and it’s a powder copper alloy.

Pangea Aerospace owns the exclusive capabilities for developing this material in Europe. Meant for developing rocket engine combustion chambers, the GRCop42 was also adapted by NASA for additive manufacturing.

Additive manufacturing, commonly known as 3D printing, is one of the techniques that’s taking center stage at the moment. Rapid manufacturing, reusability, lower costs and increased performance are the main advantages of 3D printing, combined with the innovative materials.

According to Pangea, this will be the world’s first copper aerospike engine that’s 3D-printed. DLR will conduct engine tests for this innovative propulsion technology at its Lampoldshausen site, a facility with unique testing infrastructure in Europe.