Did you know that there are excavators out there that rely on telescopic and tilting booms instead of conventional knuckle booms? The American manufacturer Gradall Industries is making this kind of weird machinery. And now it partnered with Volvo Penta to turn such a vehicle into an electric workhorse.

Gradall has been making excavators for over 75 years, so these guys know one or two things about them. That’s why they thought of doing these machines differently. They are not the only ones to use the idea of a telescopic boom, but they are now the first to combine it with an electric drive.

But first, let’s see what’s so special about this unconventional boom. I don’t know about you, but excavators were my favorites when I was a kid. Even today there are many videos on YouTube and Facebook where skilled people make excavators look kind of cool.

Basically, a conventional excavator has a knuckle boom and a complicated hydraulic system. It digs, lifts the cup, and rotates to discard the contents into a tipper. Dig, lift, rotate, discard, and repeat. It sounds boring, that’s for sure.

The Gradall system is also boring, but according to the company this solution helps the worker “get more work done by the end of every day.” So, why is the tilting & telescoping boom more efficient than the knuckle boom?

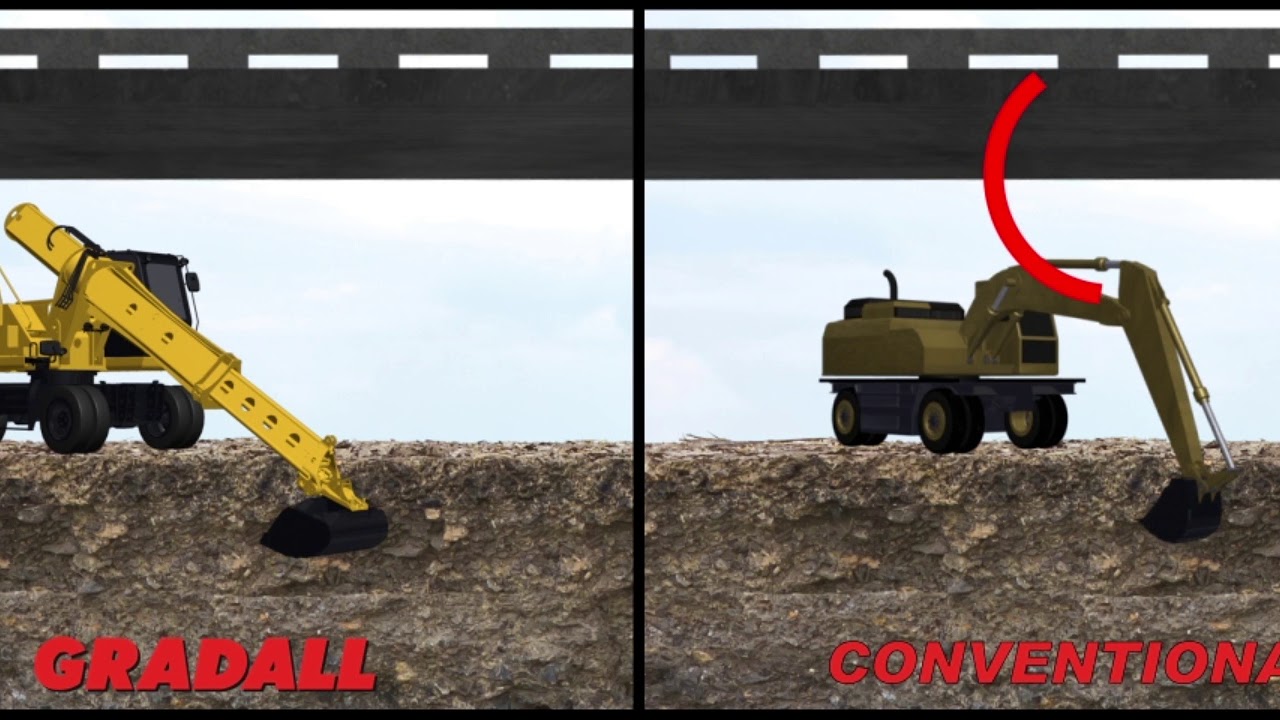

It seems that the knuckle boom design is plagued by a reduction in force at stick angles over 90°. By comparison, the telescoping design delivers full power through the entire dig cycle. I’ll let the construction engineers debate the pros and cons of this important piece of information.

In the meantime, I find more useful the fact that the unconventional boom is more appropriate for height-restricted places, where the conventional boom doesn’t reach. Also, it’s easier for the operator to see the full length of the boom, while the controls are simpler.

Have you ever seen a video with expensive fails, when the operator tries to load the excavator on a platform, and it falls on its side? Well, the Gradall XL 4100V has a huge advantage, because it doesn’t need a ride. It has lots of wheels, and it is highway speed capable.

This is a huge thing for people in logistics because not needing an extra truck and trailer means cost reductions and time efficiency. The wheeled excavator can be driven at 60 mph (95 kph), so it can get fast enough to any place needed. The operator is also the driver.

But there’s one problem – this vehicle has a diesel engine. Volvo Penta is the exclusive supplier of 5- and 8-liter Tier 4 diesel engines for Gradall’s wheeled telescopic boom excavator. So, this vehicle is polluting and noisy, especially at the construction site.

Because sustainability demands and regulations have become more and more stringent, Volvo Penta and Gradall decided to make the first step into electromobility. And now they unveiled the prototype of electric version EL41H4 at CONEXPO.

The 94-kWh double-battery is said to source energy for both the powertrain of the vehicle and the electric machine power take-off needed for the hydraulic system controlling the boom. Full-charging the depleted batteries from a 150 kW DC fast-charging point should take around 45 minutes. That’s about the same time as the lunch break for the operator.

Volvo Penta supplied the batteries, but also the electric motors, gearboxes, inverters, junction boxes, and cabling. The high-voltage system fits neatly into the existing engine bay, which is a huge advantage in terms of quick conversion.

The vehicle will undergo extensive testing and optimization before getting approved by authorities. Besides, Gradall and Volvo Penta are already considering broadening their partnership for converting other machinery.

There you are, just another example of how logical it is for construction machinery to be powered by electric motors and batteries. This unconventional excavator joining the trend of electromobility is a clear sign that manufacturers of working machinery see a real benefit in it.

But first, let’s see what’s so special about this unconventional boom. I don’t know about you, but excavators were my favorites when I was a kid. Even today there are many videos on YouTube and Facebook where skilled people make excavators look kind of cool.

Basically, a conventional excavator has a knuckle boom and a complicated hydraulic system. It digs, lifts the cup, and rotates to discard the contents into a tipper. Dig, lift, rotate, discard, and repeat. It sounds boring, that’s for sure.

The Gradall system is also boring, but according to the company this solution helps the worker “get more work done by the end of every day.” So, why is the tilting & telescoping boom more efficient than the knuckle boom?

In the meantime, I find more useful the fact that the unconventional boom is more appropriate for height-restricted places, where the conventional boom doesn’t reach. Also, it’s easier for the operator to see the full length of the boom, while the controls are simpler.

Have you ever seen a video with expensive fails, when the operator tries to load the excavator on a platform, and it falls on its side? Well, the Gradall XL 4100V has a huge advantage, because it doesn’t need a ride. It has lots of wheels, and it is highway speed capable.

This is a huge thing for people in logistics because not needing an extra truck and trailer means cost reductions and time efficiency. The wheeled excavator can be driven at 60 mph (95 kph), so it can get fast enough to any place needed. The operator is also the driver.

But there’s one problem – this vehicle has a diesel engine. Volvo Penta is the exclusive supplier of 5- and 8-liter Tier 4 diesel engines for Gradall’s wheeled telescopic boom excavator. So, this vehicle is polluting and noisy, especially at the construction site.

The 94-kWh double-battery is said to source energy for both the powertrain of the vehicle and the electric machine power take-off needed for the hydraulic system controlling the boom. Full-charging the depleted batteries from a 150 kW DC fast-charging point should take around 45 minutes. That’s about the same time as the lunch break for the operator.

Volvo Penta supplied the batteries, but also the electric motors, gearboxes, inverters, junction boxes, and cabling. The high-voltage system fits neatly into the existing engine bay, which is a huge advantage in terms of quick conversion.

The vehicle will undergo extensive testing and optimization before getting approved by authorities. Besides, Gradall and Volvo Penta are already considering broadening their partnership for converting other machinery.

There you are, just another example of how logical it is for construction machinery to be powered by electric motors and batteries. This unconventional excavator joining the trend of electromobility is a clear sign that manufacturers of working machinery see a real benefit in it.