Volkswagen revealed more details about the rear-axle drive APP550, the brand-new electric drivetrain for the ID. family. The German automaker claims it provides more power and increased efficiency. Let’s take a closer look at it.

Volkswagen has engineered a particular vehicle architecture for its electric models, the modular electric drive (MEB) platform. The ID.7 will be the latest addition to the ID. family and the sixth EV to be based on MEB – its debut is scheduled in five days, on April 17.

Even though MEB remained the same, Volkswagen still wanted to come up with an innovation that boosted the performance and efficiency of its EVs. The company’s Technical Development and Group Components team delivered, with an added benefit on top: reduced use of raw materials.

The new powertrain develops 286 ps (282 hp or 210 kW) and a peak torque of about 550 Nm (406 lb-ft), which can differ depending on the vehicle’s gear ratio. The upgraded torque allows vehicles to output more power, both from a standstill and at higher speeds.

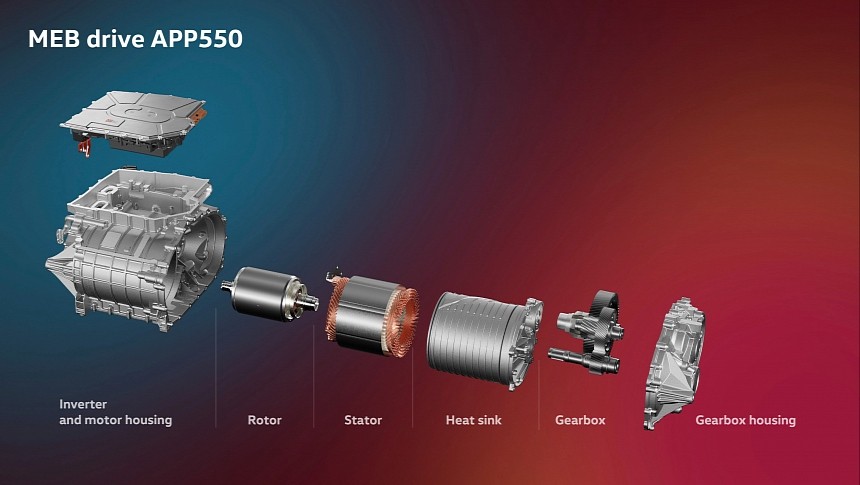

What enables the APP550 drive to develop more torque is an improved stator that features a higher effective number of windings and a larger wire cross-section. What’s more, its counterpart, the rotor, is fitted with a more powerful magnet that boasts a higher load capacity. The drive was reinforced to be able to support the increased torque.

Another critical component of any electric drive is the inverter. Volkswagen’s new-gen drivetrain features an enhanced inverter engineered to supply the necessary high-phase current that enables greater power and efficiency. In simpler terms, it acts as the “brain” of the power train, and its software makes sure the system processes run smoothly.

The automaker optimized several components in the powertrain to improve the efficiency of the electric drive, such as the thermal management system. APP550’s energy-saving cooling system now operates without electrically driven oil – instead, it cools itself through the gear wheels of the gearbox and the specially designed components for oil supply and distribution. The vehicle’s coolant circuit keeps the oil’s temperature low, ensuring the entire drive operates at an optimum temperature. Furthermore, the outside of the stator integrates a water heat sink.

Alexander Krick, the Head of Technical Development E-Drive, Power Electronics & Transmission at Group Components, explained that Volkswagen has been developing electric drive motors and their gearboxes for 15 years. In the last ten years, they have been manufactured at the Volkswagen Group Components plant in Kassel, Germany, which has also benefitted from several upgrades, like special electrical sheets and customized machining processes. The APP550 drive, along with the gearbox, rotor, and stator, will be produced there.

The new drivetrain was designed for 77 to 86 kWh battery sizes and will be introduced in the fourth quarter of 2023.

Even though MEB remained the same, Volkswagen still wanted to come up with an innovation that boosted the performance and efficiency of its EVs. The company’s Technical Development and Group Components team delivered, with an added benefit on top: reduced use of raw materials.

The new powertrain develops 286 ps (282 hp or 210 kW) and a peak torque of about 550 Nm (406 lb-ft), which can differ depending on the vehicle’s gear ratio. The upgraded torque allows vehicles to output more power, both from a standstill and at higher speeds.

What enables the APP550 drive to develop more torque is an improved stator that features a higher effective number of windings and a larger wire cross-section. What’s more, its counterpart, the rotor, is fitted with a more powerful magnet that boasts a higher load capacity. The drive was reinforced to be able to support the increased torque.

Another critical component of any electric drive is the inverter. Volkswagen’s new-gen drivetrain features an enhanced inverter engineered to supply the necessary high-phase current that enables greater power and efficiency. In simpler terms, it acts as the “brain” of the power train, and its software makes sure the system processes run smoothly.

The automaker optimized several components in the powertrain to improve the efficiency of the electric drive, such as the thermal management system. APP550’s energy-saving cooling system now operates without electrically driven oil – instead, it cools itself through the gear wheels of the gearbox and the specially designed components for oil supply and distribution. The vehicle’s coolant circuit keeps the oil’s temperature low, ensuring the entire drive operates at an optimum temperature. Furthermore, the outside of the stator integrates a water heat sink.

Alexander Krick, the Head of Technical Development E-Drive, Power Electronics & Transmission at Group Components, explained that Volkswagen has been developing electric drive motors and their gearboxes for 15 years. In the last ten years, they have been manufactured at the Volkswagen Group Components plant in Kassel, Germany, which has also benefitted from several upgrades, like special electrical sheets and customized machining processes. The APP550 drive, along with the gearbox, rotor, and stator, will be produced there.

The new drivetrain was designed for 77 to 86 kWh battery sizes and will be introduced in the fourth quarter of 2023.