Our current level of technological development does not allow us to build things in space. In the best-case scenario, we are capable of assembling stuff in orbit, but the actual build of structures and whatnot still takes place on Earth.

It's clear to anyone looking that if we are to truly become a space-faring civilization we'll have to start building ships right up there, where they are meant to operate. It will take a very, very long time to reach a point when shipyards will float above our planet, but it's somewhat encouraging to know the first shy steps to that future are being taken today, during our lifetime.

The key to the future of in-space manufacturing seems to be 3D printers. You all know the tech by now, as it is used in pretty much all aspects of life, from making toy figurines to creating parts for automobiles and rockets.

3D printers have even been sent to space, to be tested on the International Space Station (ISS). On several occasions, polymer-based printers were shipped to the station to see what they could do. And they did what they were intended to do, depositing layer upon layer of heated plastic material to create the desired part.

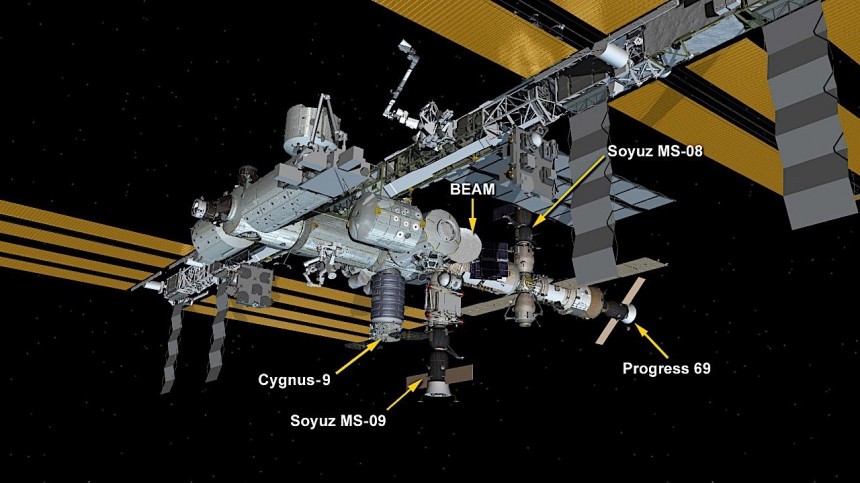

A couple of days ago, a Cygnus spacecraft took off for the ISS, carrying with it much-needed supplies for the astronauts on the station. Its cargo manifest also includes a 3D printer.

It's not of the variety the ISS has received before, but one that can 3D print metal. It is for the first time in history such a piece of hardware makes the trip to orbit, and its presence up there might have some interesting side effects.

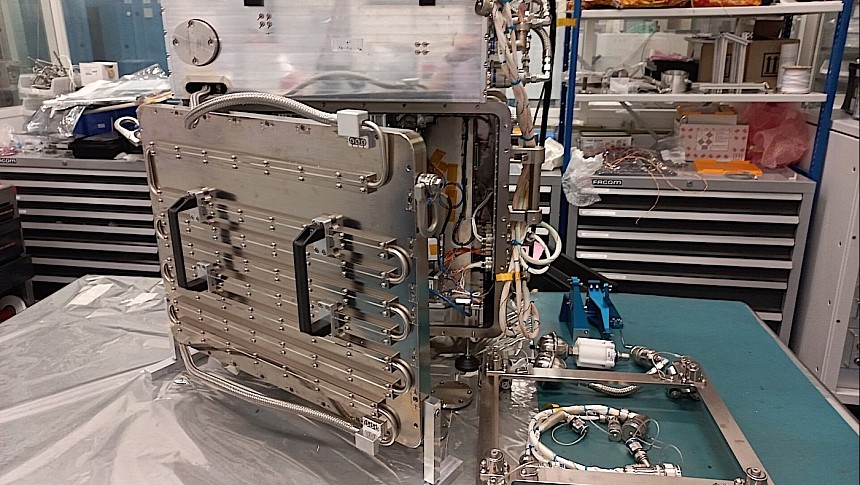

The printer is the product of a European team of companies led by Airbus, and it weighs a massive 180 kg (397 pounds). Once on the station, it will be installed on the European Space Agency's (ESA) Columbus module.

Once in position, the hardware will start doing something that has never been done in space before: 3D print metal parts. Here's what that means.

The printer uses for raw material a variety of stainless steel we generally get in medical implants and water treatment. It's highly resistant to corrosion and has a melting point of about 1,400 degrees Celsius (2,552 degrees Fahrenheit).

In its raw form the steel is fed into the printing area, where a laser awaits for it. The beam of light is roughly one million times more powerful than the pointers some of us use to play tricks on friends. The laser forces the metal to reach its melting point and transform into a melt pool.

Now don't go imagining something the likes of the pool of molten metal the Terminator sank into. This one is just a millimeter across, and that helps not only with the printer's own operation but also prevents the metal from flying around uncontrollably in the zero-g environment, thanks to surface tension.

Once that happens the molten metal is added to the printer, which starts building the desired object one layer at a time.

Because of the very high temperatures reached during operation and the fumes resulting from the process, the printer is encased in a fully sealed box. Moreover, it will not be operated from the station, but controlled from Earth instead.

To make sure the end products meet standards, the printer's internal oxygen atmosphere is vented before the start of operations and gets filled instead with nitrogen that does not oxidize the hot metal.

The Europeans have set the target to print four differently shaped objects. We don't know exactly what they are, but we do know their exact twins already exist here on Earth, printed through the same means.

The existing shapes will be used as reference prints and compared to the ones produced in space to determine the effects of weightlessness on the printing process and on the end products – sometime in the future, the space-printed shapes will be sent back to Earth for analysis.

All four objects are smaller in size than a soda can and weigh 250 grams each. The printer will work four hours per day for a total of up to four weeks to complete a single one. The limited daily operation time is called for because the printer is very noisy, and it seems there are noise regulations to mind up there on the ISS.

The goal of this entire exercise is to "prove the potential of metal 3D printing in space." It marks the first small step to a future when in-orbit large infrastructure manufacturing and assembly will be possible. And that will really open up space for us, giving humanity safer and faster access to the Moon and Mars.

Before we get there, though, such technologies could be used, for instance, to repurpose bits from old satellites into new structures, tools, and parts, eliminating the costly need to launch a rocket to deliver them to orbit.

The key to the future of in-space manufacturing seems to be 3D printers. You all know the tech by now, as it is used in pretty much all aspects of life, from making toy figurines to creating parts for automobiles and rockets.

3D printers have even been sent to space, to be tested on the International Space Station (ISS). On several occasions, polymer-based printers were shipped to the station to see what they could do. And they did what they were intended to do, depositing layer upon layer of heated plastic material to create the desired part.

A couple of days ago, a Cygnus spacecraft took off for the ISS, carrying with it much-needed supplies for the astronauts on the station. Its cargo manifest also includes a 3D printer.

It's not of the variety the ISS has received before, but one that can 3D print metal. It is for the first time in history such a piece of hardware makes the trip to orbit, and its presence up there might have some interesting side effects.

The printer is the product of a European team of companies led by Airbus, and it weighs a massive 180 kg (397 pounds). Once on the station, it will be installed on the European Space Agency's (ESA) Columbus module.

The printer uses for raw material a variety of stainless steel we generally get in medical implants and water treatment. It's highly resistant to corrosion and has a melting point of about 1,400 degrees Celsius (2,552 degrees Fahrenheit).

In its raw form the steel is fed into the printing area, where a laser awaits for it. The beam of light is roughly one million times more powerful than the pointers some of us use to play tricks on friends. The laser forces the metal to reach its melting point and transform into a melt pool.

Now don't go imagining something the likes of the pool of molten metal the Terminator sank into. This one is just a millimeter across, and that helps not only with the printer's own operation but also prevents the metal from flying around uncontrollably in the zero-g environment, thanks to surface tension.

Once that happens the molten metal is added to the printer, which starts building the desired object one layer at a time.

Because of the very high temperatures reached during operation and the fumes resulting from the process, the printer is encased in a fully sealed box. Moreover, it will not be operated from the station, but controlled from Earth instead.

The Europeans have set the target to print four differently shaped objects. We don't know exactly what they are, but we do know their exact twins already exist here on Earth, printed through the same means.

The existing shapes will be used as reference prints and compared to the ones produced in space to determine the effects of weightlessness on the printing process and on the end products – sometime in the future, the space-printed shapes will be sent back to Earth for analysis.

All four objects are smaller in size than a soda can and weigh 250 grams each. The printer will work four hours per day for a total of up to four weeks to complete a single one. The limited daily operation time is called for because the printer is very noisy, and it seems there are noise regulations to mind up there on the ISS.

The goal of this entire exercise is to "prove the potential of metal 3D printing in space." It marks the first small step to a future when in-orbit large infrastructure manufacturing and assembly will be possible. And that will really open up space for us, giving humanity safer and faster access to the Moon and Mars.

Before we get there, though, such technologies could be used, for instance, to repurpose bits from old satellites into new structures, tools, and parts, eliminating the costly need to launch a rocket to deliver them to orbit.