We could all probably draw a rough sketch of a booster rocket and its engine if needed. You know, a giant pointy metal cylinder tapering into a spire at the top end and a bell-like shape at the bottom, where the engines are located. It's a basic silhouette as old as human-crewed spaceflight itself. But that doesn't mean all rocket engines are built the same. Some are just "built different."

Perhaps no type of rocket motor ever designed looks more radically different than what we've all come to expect than aerospike engines. Among the handful of aerospikes ever manufactured, one king of the roost is routinely lauded as one of the finest ever built. Depending on who you talk to, you might hear it was a travesty that this engine never made it onto a spacecraft. This is the story of the Rocketdyne XRS-2200, a mouthful of a name for sure.

But trust us, the XRS-2200 was like the LS7 of aerospikes. So to say, it was the largest, most powerful of its type in the world when it was first run in a static test in 1999. Even today, no other engine of its kind has come close to the same power output. But to understand the impetus behind this long-defunct engine project, you need to know why rocket engineers would bother building such a profoundly different-looking rocket engine platform in the first place.

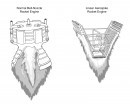

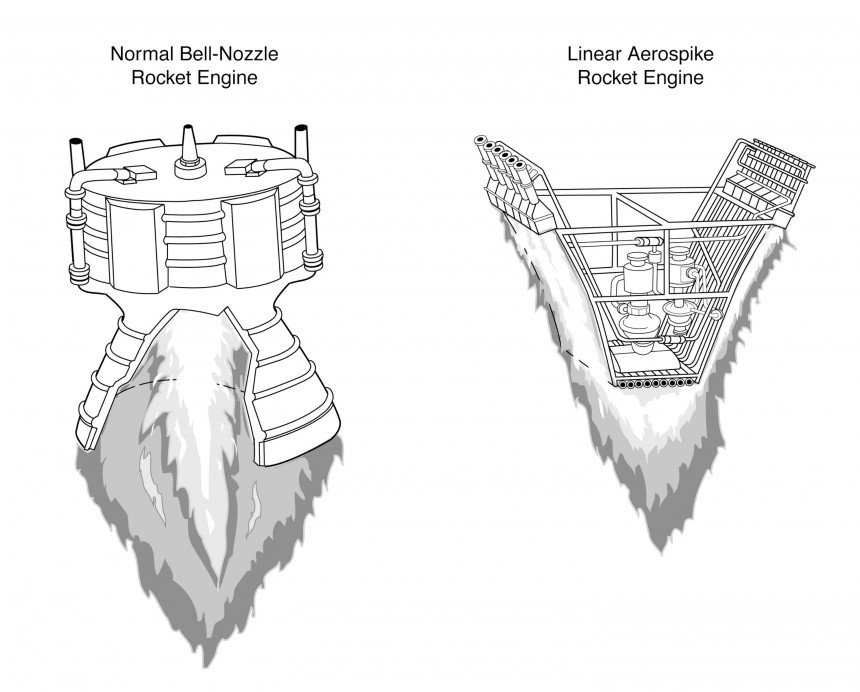

Despite the radical visual differences, linear aerospike engines still operate on the same working principles of a bell-shaped rocket motor a ten-year-old might doodle in a notebook. In short, a "spicy" mixture of liquid propellant and an oxidizer are stored in separate tanks at launch before mixing together in a combustion chamber and igniting when the launch clock timer reaches T-zero seconds. The resulting super-heated gasses begin a controlled explosion out of a rocket motor's exhaust, where the all-too-familiar exhaust bell directs all the engine's power in the opposite direction of wherever it wants to travel.

It's all pretty standard operating procedure regardless of the shape of the rocket, bar anything crazy like nuclear propulsion. The problems arise not at liftoff but rather as a booster rocket rises through the lower atmosphere and into the upper fringes before the near-vacuum of the Karman Line, some 100 kilometers (62 m) above sea level. At such high altitudes, the ambient air pressure, fractions as dense as on Earth's surface, causes the gasses expelled by bell-tipped rocket exhausts to start acting strange.

As the air pressure nears absolute zero, exhaust gasses that flowed out almost effortlessly at launch begins to linger inside the bell shape of a typical rocket's exhaust nozzle. This phenomenon, at least according to NASA research, can lead to inefficiencies in engine performance at the highest reaches of the atmosphere. That's not as much of a problem with multi-stage rockets like the Saturn V or the modern SLS, with second-stage engines optimized for high-altitude and space vacuum operation.

But this problem suddenly becomes a massive pain in the you-know-what when dealing with one particularly desirable form of spacecraft. That, of course, would be single-stage-to-orbit (SSTO) re-useable spaceplanes. Whether the linear variety, like the XRS-2200, or the slightly more conventional toroidal shape, Aerospike engines that direct all of the combusted fuel into a downward "spike" formation, no matter the altitude, were practically tailor-made for SSTOs. All for the reason that they're more efficient in the upper atmosphere and deep space.

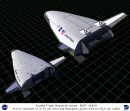

These same SSTOs were, at one point, poised to supplement and one day replace the American space shuttle. Enter the Lockheed Martin X-33, the sub-orbital technological demonstrator for what the secretive Lockheed-Martin Skunk Works called the VentureStar. As Lockheed-Martin's proposal for an SSTO replacement for the Space Shuttle, the Venture Star was a quantum leap in human-crewed spacecraft technology. That was, assuming the project could get off the ground.

For that to happen, Lockheed-Martin contracted the iconic Rocketdyne company of Apollo Saturn V fame to develop and manufacture an aerospike engine which internally was much the same as a normal bell-shaped rocket motor. Of course, the end product was nothing ordinary in the slightest. At its core, the XRS-2200 utilized much the same internal architecture as the rocket motor used in the second and third stages of the Apollo-era Saturn V, the Rocketdyne J-2.

The XRS-2200 was based on the J-2's upgraded J-2S form, intended for future upgrades of the Saturn V with more streamlined fuel plumbing and a reworked throttling system. Though these never made it onto an Apollo mission, all their internals were put to great use in the XRS-2200. All of the engine's plumbing, including the turbopumps that feed the fuel and oxidizer, is housed in an internal tubular chassis that feeds to two banks of rocket nozzles arranged in a manner reminiscent of the V in an internal combustion engine.

It's at this stage that the exhaust gasses are directed downward, following the contour engine's spike-shaped nozzle for the duration of the flight. Using a combination of cryogenically cooled liquid hydrogen propellant with liquid oxygen as the oxidizer, it made for an engine that jetted 1,184 kN (266,999 lbs) of thrust in a vacuum and 909 kN (204,000 lbs) at sea level while maintaining a chamber pressure of 58 bar (840 psi). When the XRS-2200 was first fired up in 1999 at the Stennis Space Center in Mississippi, it looked like Rocketdyne was onto something.

If nothing else, it was quite a spectacular light show. Had everything gone according to plans, two XRS-2200s were to be integrated into the X-33 space plane for further testing before being put into production under the name RS-2200 in the SSTO VentureStar shuttle. But there was one massive problem. Though the rocket motor itself functioned more-or-less normally, the X-33's novel composite metal pressurized fuel tanks seemed to fail again and again as testing moved forward.

The end result of all the research was damning. Declaring in no uncertain terms that the technology needed to store and effectively pump cryogenic propellants was not advanced enough to reliably sustain an aerospike sub-orbital space plane like the X-33, let alone an SSTO vessel like the planned VentureStar. By 2001, the X-33 program had been canceled. With its launch complex already complete and the first prototype not far behind, it was the last time NASA genuinely took an aerospike-based SSTO proposal seriously.

Ironically, Lockheed-Martin's aerospace-sector rival Northrop Grumman was able to develop cryogenic fuel tanks just three years later, in 2004. Doing so was one of the first technological innovations achieved under NASA's Constellation program to get humans back onto the Moon and then to Mars. In 2017, the remnants of Constellation, these novel fuel tanks included, became known as the Artemis program, as did the Orion spacecraft. It isn't quite the silver lining that makes the $1 billion spent by NASA and Lockheed-Martin worthwhile in the end, but it's at least something.

As for SSTO spaceplanes, it appears as though the technology to make them viable still isn't quite there. Even indirect replacements to the now-retired Space Shuttle due to launch like Sierra Space's Dream Chaser employ expendable booster rockets to get into orbit. But if anyone ever decides to try again, and there's every reason to think someone will eventually, don't be surprised if they dust off some old Rocketdyne blueprints to draw inspiration from.

What this proves, in a nutshell, is that scientific progress, unlike the XRS-2200, isn't linear at all sometimes. If you give us a timeline of the history of human-crewed spaceflight, we'll tell you a story of taking one step forward, then two steps back, before finally making that one giant leap for mankind. That's why it isn't always the end of the world when a big aerospace project bites the dust before its day is due. There's usually something better waiting in the wing.

But trust us, the XRS-2200 was like the LS7 of aerospikes. So to say, it was the largest, most powerful of its type in the world when it was first run in a static test in 1999. Even today, no other engine of its kind has come close to the same power output. But to understand the impetus behind this long-defunct engine project, you need to know why rocket engineers would bother building such a profoundly different-looking rocket engine platform in the first place.

Despite the radical visual differences, linear aerospike engines still operate on the same working principles of a bell-shaped rocket motor a ten-year-old might doodle in a notebook. In short, a "spicy" mixture of liquid propellant and an oxidizer are stored in separate tanks at launch before mixing together in a combustion chamber and igniting when the launch clock timer reaches T-zero seconds. The resulting super-heated gasses begin a controlled explosion out of a rocket motor's exhaust, where the all-too-familiar exhaust bell directs all the engine's power in the opposite direction of wherever it wants to travel.

It's all pretty standard operating procedure regardless of the shape of the rocket, bar anything crazy like nuclear propulsion. The problems arise not at liftoff but rather as a booster rocket rises through the lower atmosphere and into the upper fringes before the near-vacuum of the Karman Line, some 100 kilometers (62 m) above sea level. At such high altitudes, the ambient air pressure, fractions as dense as on Earth's surface, causes the gasses expelled by bell-tipped rocket exhausts to start acting strange.

But this problem suddenly becomes a massive pain in the you-know-what when dealing with one particularly desirable form of spacecraft. That, of course, would be single-stage-to-orbit (SSTO) re-useable spaceplanes. Whether the linear variety, like the XRS-2200, or the slightly more conventional toroidal shape, Aerospike engines that direct all of the combusted fuel into a downward "spike" formation, no matter the altitude, were practically tailor-made for SSTOs. All for the reason that they're more efficient in the upper atmosphere and deep space.

These same SSTOs were, at one point, poised to supplement and one day replace the American space shuttle. Enter the Lockheed Martin X-33, the sub-orbital technological demonstrator for what the secretive Lockheed-Martin Skunk Works called the VentureStar. As Lockheed-Martin's proposal for an SSTO replacement for the Space Shuttle, the Venture Star was a quantum leap in human-crewed spacecraft technology. That was, assuming the project could get off the ground.

For that to happen, Lockheed-Martin contracted the iconic Rocketdyne company of Apollo Saturn V fame to develop and manufacture an aerospike engine which internally was much the same as a normal bell-shaped rocket motor. Of course, the end product was nothing ordinary in the slightest. At its core, the XRS-2200 utilized much the same internal architecture as the rocket motor used in the second and third stages of the Apollo-era Saturn V, the Rocketdyne J-2.

It's at this stage that the exhaust gasses are directed downward, following the contour engine's spike-shaped nozzle for the duration of the flight. Using a combination of cryogenically cooled liquid hydrogen propellant with liquid oxygen as the oxidizer, it made for an engine that jetted 1,184 kN (266,999 lbs) of thrust in a vacuum and 909 kN (204,000 lbs) at sea level while maintaining a chamber pressure of 58 bar (840 psi). When the XRS-2200 was first fired up in 1999 at the Stennis Space Center in Mississippi, it looked like Rocketdyne was onto something.

If nothing else, it was quite a spectacular light show. Had everything gone according to plans, two XRS-2200s were to be integrated into the X-33 space plane for further testing before being put into production under the name RS-2200 in the SSTO VentureStar shuttle. But there was one massive problem. Though the rocket motor itself functioned more-or-less normally, the X-33's novel composite metal pressurized fuel tanks seemed to fail again and again as testing moved forward.

The end result of all the research was damning. Declaring in no uncertain terms that the technology needed to store and effectively pump cryogenic propellants was not advanced enough to reliably sustain an aerospike sub-orbital space plane like the X-33, let alone an SSTO vessel like the planned VentureStar. By 2001, the X-33 program had been canceled. With its launch complex already complete and the first prototype not far behind, it was the last time NASA genuinely took an aerospike-based SSTO proposal seriously.

As for SSTO spaceplanes, it appears as though the technology to make them viable still isn't quite there. Even indirect replacements to the now-retired Space Shuttle due to launch like Sierra Space's Dream Chaser employ expendable booster rockets to get into orbit. But if anyone ever decides to try again, and there's every reason to think someone will eventually, don't be surprised if they dust off some old Rocketdyne blueprints to draw inspiration from.

What this proves, in a nutshell, is that scientific progress, unlike the XRS-2200, isn't linear at all sometimes. If you give us a timeline of the history of human-crewed spaceflight, we'll tell you a story of taking one step forward, then two steps back, before finally making that one giant leap for mankind. That's why it isn't always the end of the world when a big aerospace project bites the dust before its day is due. There's usually something better waiting in the wing.