As you might know, I'm into the whole off-grid living and solar power lifestyle. That said, I was out exploring the latest news in sun-capturing technology, and guess who I ran across working their magic? MIT, and this time around, we're looking at cells thinner than human hair. But the real ticket here is that we're on our way to scalable and affordable production of this fresh magic, and that means a whole lot for several industries.

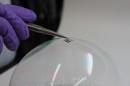

Around six years ago, engineers at MIT hit the world with their latest advancement in solar cell technology. They showed the world how they could build a cell that's as light as a soap bubble. No joke. However, the old way of doing things was rather expensive, and so solutions were sought out, bringing us to December 2022.

While most of us were getting ready for the holidays, researchers and engineers at MIT have come up with a way to produce similar light and thin cells like the ones mentioned in the soap bubble experiment, but this time around, they're able to mass-produce the stuff, and furthermore, they're more durable, more flexible, and pound for pound, produce 18 times more energy than traditional silicon cells. Do you know what this means? RVing is about to get a whole lot better.

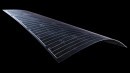

Come to think of it, several industries will be able to benefit from this newfound fabrication process. From RVs to cars, to airplanes, to drones, to boating, and even, wait for it, textiles and fabrics will be able to adopt this stuff. Actually, fabrics are a key ingredient in this way of producing arrays, so let's dive into the production process.

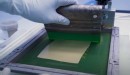

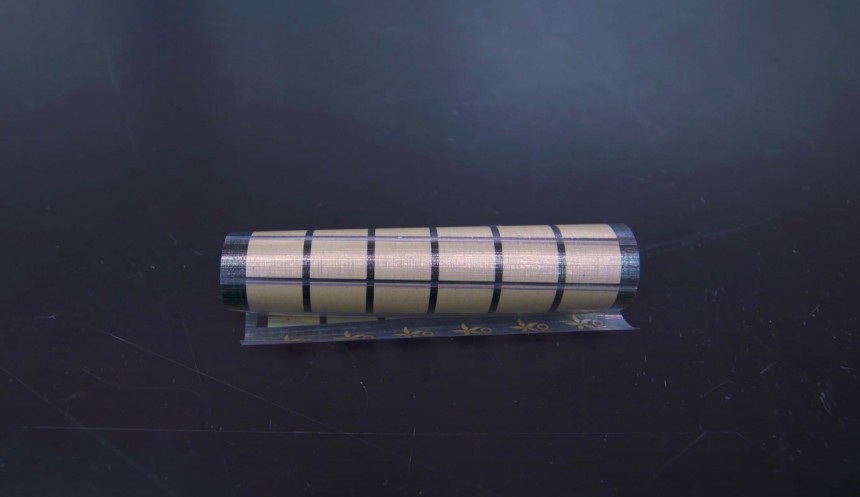

Now, what we're looking at here may sound a bit strange, but I think it's absolutely genius. The way each cell is built is by simply spraying a 3-micron-thick plastic substrate with a semiconducting ink. Yes, we're basically building solar-powered T-shirts, and that's mind-blowing if you ask me. There's a bit more to it than that, but I'll try to keep things as simple as I can. Once an electrode is added, the module is complete, and the 15 microns of flexible array is peeled off the substrate.

But there's a problem, a "freestanding" cell is brittle and can "easily tear." After all, it's basically dried-up layers of ink, so to offer a base for allowing the flexibility of the cells to remain unhindered while protecting them, the modules are applied to a layer of Dyneema with UV-curable glue. If you've never heard of Dyneema, it's a material weaved from Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers that - weight for weight - are reputed to be 15 times stronger than steel and "exhibits a resistance five times higher than Kevlar."

Now that we know what we're up against, let's see how these cells and panels can change our society. Well, let's think about residential use. We can now replace tens, even hundreds of pounds of hardware from our roofs while maintaining, even raising, efficiency levels. For RVs, it basically means that your entire vehicle can be turned into an energy-producing machine. For the fabrics industry, well, this is where I think we will see a whole new lineup of outdoor gear designed to keep your devices running no matter where you are in the world. Just think about a backpack that produces electricity as you stroll the wilderness; all the while, your iPhone is charging its battery.

The idea with a solar-powered backpack or other outdoor goods is one that even the paper released by MIT mentions, and I quote, "For instance, they could be integrated onto the sails of a boat to provide power while at sea, adhered onto tents and tarps that are deployed in disaster recovery operations, or applied onto the wings of drones to extend their flying range." All I've got to say about that is... nice!

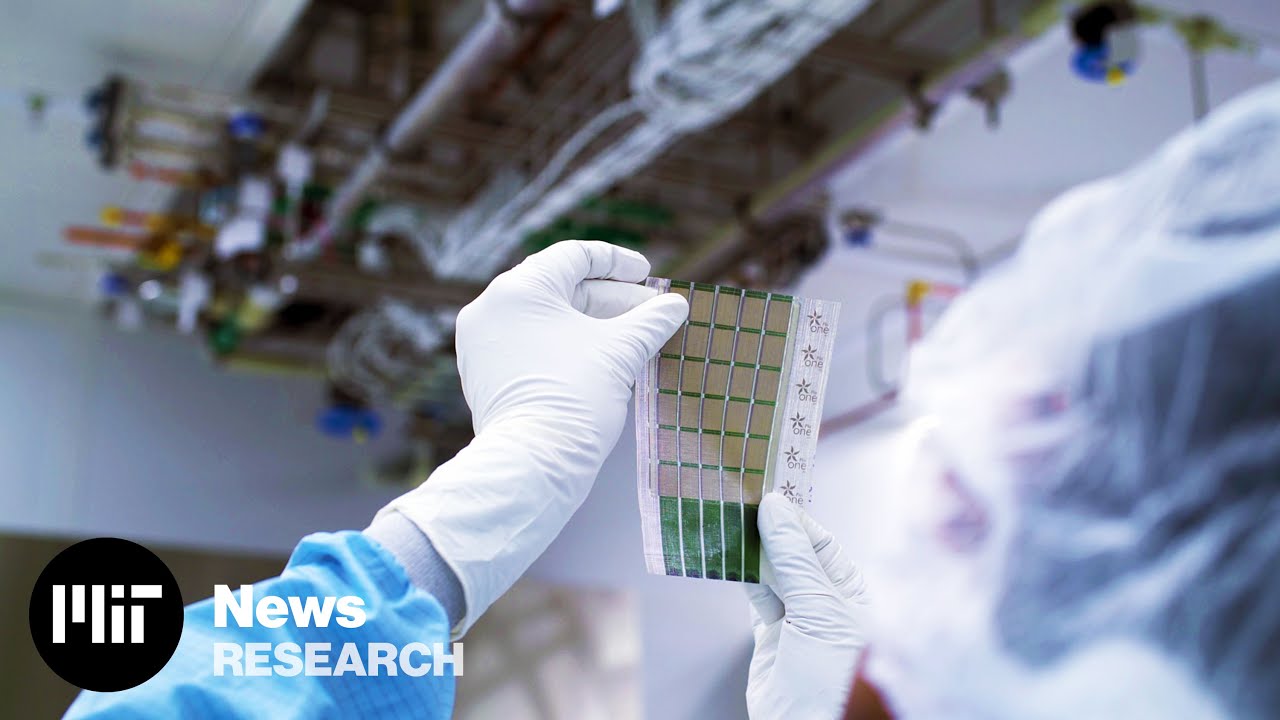

As for where things are at now, the crew at One Lab (Organic and Nanostructured Electronics Laboratory) are working on finding a suitable protective material to use so that the carbon-based modules aren't affected by the environment while also maintaining the weight-saving and efficiency properties of this new tech.

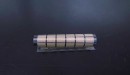

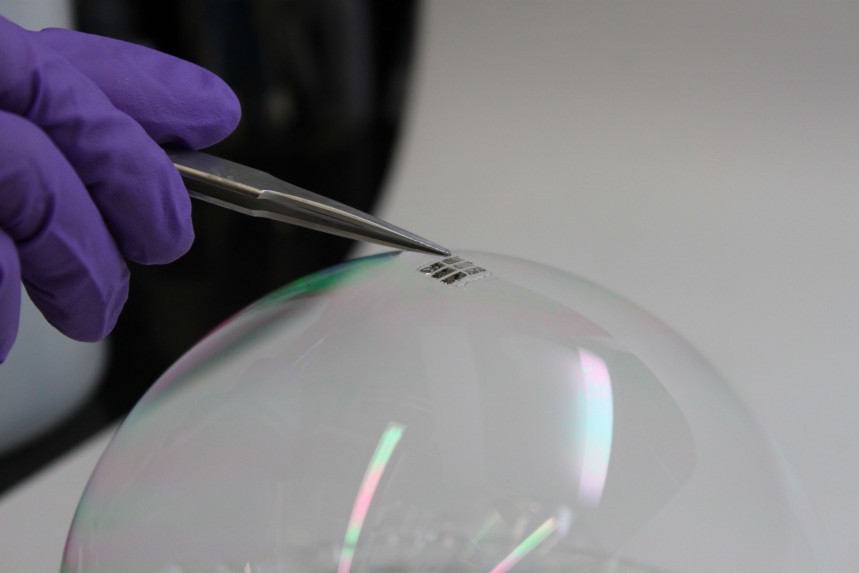

Nonetheless, even at current stages, MIT reports that these arrays are durable beyond belief. For example, after rolling and unrolling such a panel over 500 times, it still retained over 90% of its initial efficiency and power-generating capacity. I think it's safe to say that we can bid our classic and brittle silicon solar panels goodbye. Even CIGS panels are threatened here because, honestly, it won't be long until an array of objects will be covered in solar panels, and it's all thanks to MIT.

I wonder if I'll be able to cover my e-bike in this stuff and ride on as long as the sun is beating down on me. Makes you think, doesn't it? If it does, drop a comment regarding where you think things are heading.

While most of us were getting ready for the holidays, researchers and engineers at MIT have come up with a way to produce similar light and thin cells like the ones mentioned in the soap bubble experiment, but this time around, they're able to mass-produce the stuff, and furthermore, they're more durable, more flexible, and pound for pound, produce 18 times more energy than traditional silicon cells. Do you know what this means? RVing is about to get a whole lot better.

Come to think of it, several industries will be able to benefit from this newfound fabrication process. From RVs to cars, to airplanes, to drones, to boating, and even, wait for it, textiles and fabrics will be able to adopt this stuff. Actually, fabrics are a key ingredient in this way of producing arrays, so let's dive into the production process.

But there's a problem, a "freestanding" cell is brittle and can "easily tear." After all, it's basically dried-up layers of ink, so to offer a base for allowing the flexibility of the cells to remain unhindered while protecting them, the modules are applied to a layer of Dyneema with UV-curable glue. If you've never heard of Dyneema, it's a material weaved from Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers that - weight for weight - are reputed to be 15 times stronger than steel and "exhibits a resistance five times higher than Kevlar."

Now that we know what we're up against, let's see how these cells and panels can change our society. Well, let's think about residential use. We can now replace tens, even hundreds of pounds of hardware from our roofs while maintaining, even raising, efficiency levels. For RVs, it basically means that your entire vehicle can be turned into an energy-producing machine. For the fabrics industry, well, this is where I think we will see a whole new lineup of outdoor gear designed to keep your devices running no matter where you are in the world. Just think about a backpack that produces electricity as you stroll the wilderness; all the while, your iPhone is charging its battery.

As for where things are at now, the crew at One Lab (Organic and Nanostructured Electronics Laboratory) are working on finding a suitable protective material to use so that the carbon-based modules aren't affected by the environment while also maintaining the weight-saving and efficiency properties of this new tech.

Nonetheless, even at current stages, MIT reports that these arrays are durable beyond belief. For example, after rolling and unrolling such a panel over 500 times, it still retained over 90% of its initial efficiency and power-generating capacity. I think it's safe to say that we can bid our classic and brittle silicon solar panels goodbye. Even CIGS panels are threatened here because, honestly, it won't be long until an array of objects will be covered in solar panels, and it's all thanks to MIT.

I wonder if I'll be able to cover my e-bike in this stuff and ride on as long as the sun is beating down on me. Makes you think, doesn't it? If it does, drop a comment regarding where you think things are heading.