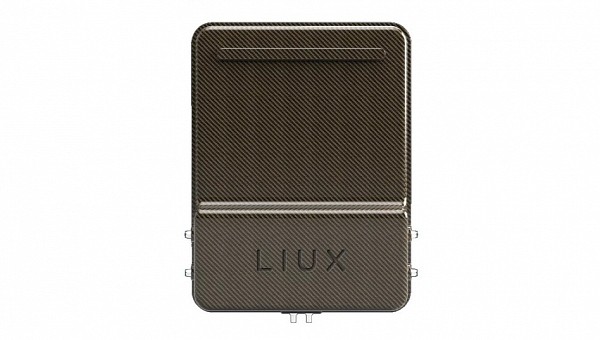

When I repeated a crucial question six times in editorials, plenty of people got mad. Predictably: too many are betting too much on a model that already showed signs that it might fail miserably. You can’t have a single component in a vehicle that will make it useless if it breaks down. That is what makes it surprising that a small Spanish startup came up with an idea that can address that. LIUX wants its EVs to have modular battery packs.

We have already written a comprehensive article on the LIUX Animal, which should be the company’s first vehicle. We also have mentioned that proposition, but I want to dissect it to demonstrate why it is a genius idea, even if it contradicts many of the current trends with battery electric cars.

LIUX conceived its products around a minimum of two and a maximum of four small battery packs. Each module offers 23 kWh. The bottom line is that you get 46 kWh in vehicles with two and 92 kWh in those with four of them. Besides the Animal, LIUX is also considering a city car similar to the smart fortwo.

The company states the more significant car will have 600 kilometers (373 miles) of range, which could mean that each module would offer 150 km (93 mi) if it were not for decreasing weight. The truth is that two modules will drive the cars further than 300 km (186 mi) because they will be much lighter. Sadly, LIUX did not disclose how much its modular battery pack weighs.

If the company were to make a different high-voltage component for each of its vehicles, that would represent higher development costs. And that is not the only advantage the idea brings: LIUX buyers may be the ones with the most benefits.

When a battery pack presents a problem, it is usually related to a few cells, not to all of them. So much so that some shops focused on electric cars try to repair that by replacing the defective modules. That is not free of controversies, and some other garages state it only appears to correct the problem: it will eventually happen again. The right fix would be to replace the entire battery pack with a new or used one in good shape. New battery packs cost around $20,000.

Now imagine that with a vehicle that has modular battery packs. If one of them is defective, the others may keep working until the defect is solved, which prevents the car from stopping in the middle of highways – as some Teslas are doing. In China, that triggered a recall that did not solve the problem: it just made the car run until its driver found a safe spot to park.

Apart from allowing the vehicle not to stop (even if with a reduced range), the modular battery packs also reduce repair costs. If a battery pack costs around $20,000, four smaller ones doing the same job should cost $5,000 each. The car company dealing with defects would also have only a fraction of the loss it has when it is necessary to replace a battery pack under warranty.

That goes against the current trend of cell-to-pack (CTP) and cell-to-body (CTB) construction. In these methods, the individual batteries are installed directly into the pack or the car's body. That increases the energy density because the cells do not have to share space with cases and other structures and elements in a module or a pack.

As much as that seems to make sense, we can only confirm it does when we are sure the batteries will last more than the car. Currently, older EVs are turning into junkyard material simply because their battery packs fail out of warranty, and it makes no financial sense to give them a new one. With the battery technology we have nowadays, it is wiser to have battery packs that you can repair or replace at lower costs. That is what makes the LIUX idea brilliant.

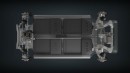

The downside is that the vehicle will be heavier than if it had a single battery pack, especially one with CTP or CTB construction. The Spanish startup will build its cars the same way BMW built the i3 and i8, which is pretty similar to body-on-frame. The main difference is that the frame (BMW called it the drive module) has three rails instead of only two. A third one in the middle is necessary to provide the support the small modular battery packs need at the center to be side by side.

The only better solution to that one is having swappable battery packs, like NIO. GAC is following the same steps and CATL and Ample proposed an even better model: with swappable battery modules. The Chinese battery maker calls its model Choco-SEBs, and they are pretty similar to what LIUX advocates. According to CATL, each Choco-SEB packs 26.5 kWh and offers a range of 200 km. These swappable modules go from one side to the other of the body, being narrow and long, but they present a problem: only three of them can fit most cars – even those with extended wheelbases. In that sense, LIUX’s idea allows for more energy (and more range).

While we do not have cells that can last a lifetime or are cheap to replace as a massive battery pack, dividing them into smaller packages is the best option for battery electric vehicles – even if that means placing four of these packages in a single car like LIUX proposes to do.

LIUX conceived its products around a minimum of two and a maximum of four small battery packs. Each module offers 23 kWh. The bottom line is that you get 46 kWh in vehicles with two and 92 kWh in those with four of them. Besides the Animal, LIUX is also considering a city car similar to the smart fortwo.

The company states the more significant car will have 600 kilometers (373 miles) of range, which could mean that each module would offer 150 km (93 mi) if it were not for decreasing weight. The truth is that two modules will drive the cars further than 300 km (186 mi) because they will be much lighter. Sadly, LIUX did not disclose how much its modular battery pack weighs.

If the company were to make a different high-voltage component for each of its vehicles, that would represent higher development costs. And that is not the only advantage the idea brings: LIUX buyers may be the ones with the most benefits.

When a battery pack presents a problem, it is usually related to a few cells, not to all of them. So much so that some shops focused on electric cars try to repair that by replacing the defective modules. That is not free of controversies, and some other garages state it only appears to correct the problem: it will eventually happen again. The right fix would be to replace the entire battery pack with a new or used one in good shape. New battery packs cost around $20,000.

Now imagine that with a vehicle that has modular battery packs. If one of them is defective, the others may keep working until the defect is solved, which prevents the car from stopping in the middle of highways – as some Teslas are doing. In China, that triggered a recall that did not solve the problem: it just made the car run until its driver found a safe spot to park.

Apart from allowing the vehicle not to stop (even if with a reduced range), the modular battery packs also reduce repair costs. If a battery pack costs around $20,000, four smaller ones doing the same job should cost $5,000 each. The car company dealing with defects would also have only a fraction of the loss it has when it is necessary to replace a battery pack under warranty.

That goes against the current trend of cell-to-pack (CTP) and cell-to-body (CTB) construction. In these methods, the individual batteries are installed directly into the pack or the car's body. That increases the energy density because the cells do not have to share space with cases and other structures and elements in a module or a pack.

As much as that seems to make sense, we can only confirm it does when we are sure the batteries will last more than the car. Currently, older EVs are turning into junkyard material simply because their battery packs fail out of warranty, and it makes no financial sense to give them a new one. With the battery technology we have nowadays, it is wiser to have battery packs that you can repair or replace at lower costs. That is what makes the LIUX idea brilliant.

The downside is that the vehicle will be heavier than if it had a single battery pack, especially one with CTP or CTB construction. The Spanish startup will build its cars the same way BMW built the i3 and i8, which is pretty similar to body-on-frame. The main difference is that the frame (BMW called it the drive module) has three rails instead of only two. A third one in the middle is necessary to provide the support the small modular battery packs need at the center to be side by side.

The only better solution to that one is having swappable battery packs, like NIO. GAC is following the same steps and CATL and Ample proposed an even better model: with swappable battery modules. The Chinese battery maker calls its model Choco-SEBs, and they are pretty similar to what LIUX advocates. According to CATL, each Choco-SEB packs 26.5 kWh and offers a range of 200 km. These swappable modules go from one side to the other of the body, being narrow and long, but they present a problem: only three of them can fit most cars – even those with extended wheelbases. In that sense, LIUX’s idea allows for more energy (and more range).

While we do not have cells that can last a lifetime or are cheap to replace as a massive battery pack, dividing them into smaller packages is the best option for battery electric vehicles – even if that means placing four of these packages in a single car like LIUX proposes to do.