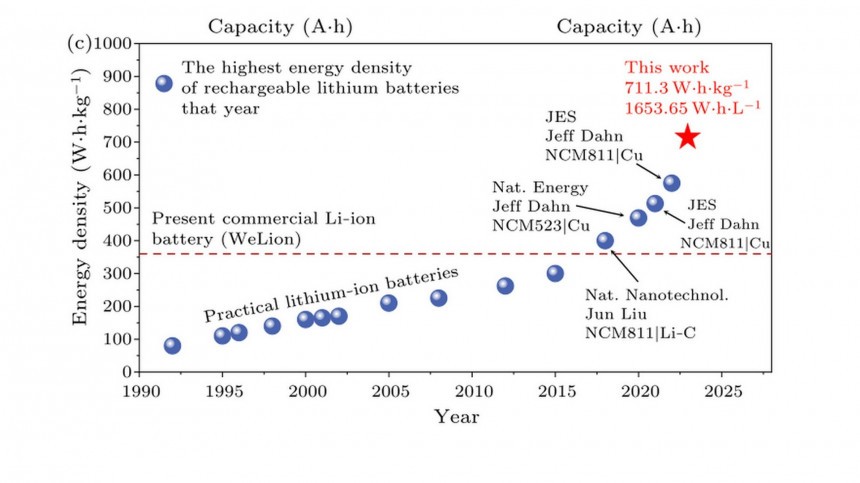

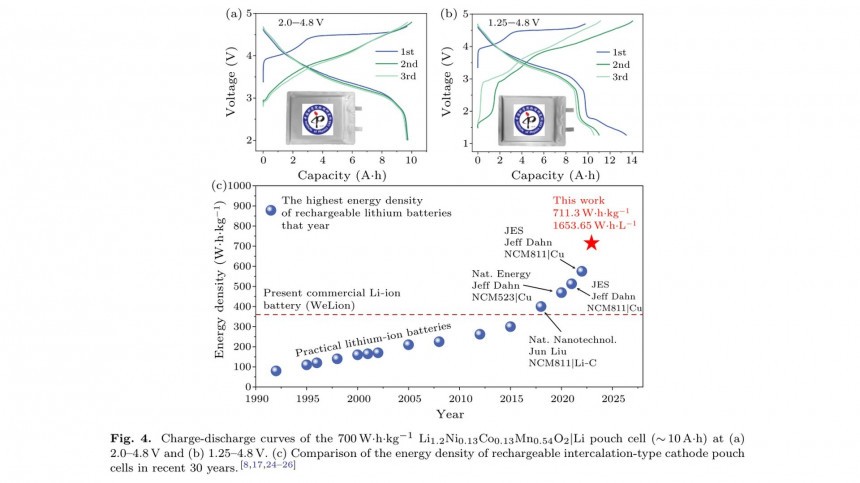

Scientists from the Beijing National Laboratory for Condensed Matter Physics have published an impressive study. They have managed to create a lithium-ion cell that delivers 711.3 Wh/kg and 1,653.65 Wh/l, the highest energy densities ever achieved by this kind of battery. As promising as that is, it is also all that it is at the moment: an amazing promise.

In these years covering battery electric vehicles (BEVs) and all studies that present bright new outlooks for cells, true progress has been a lot slower than most people would care to admit. Having the perspective of higher energy density is great, but it only really matters when it is ready for production. More than that, when these batteries can cope with the demanding requirements they will have to meet for vehicles.

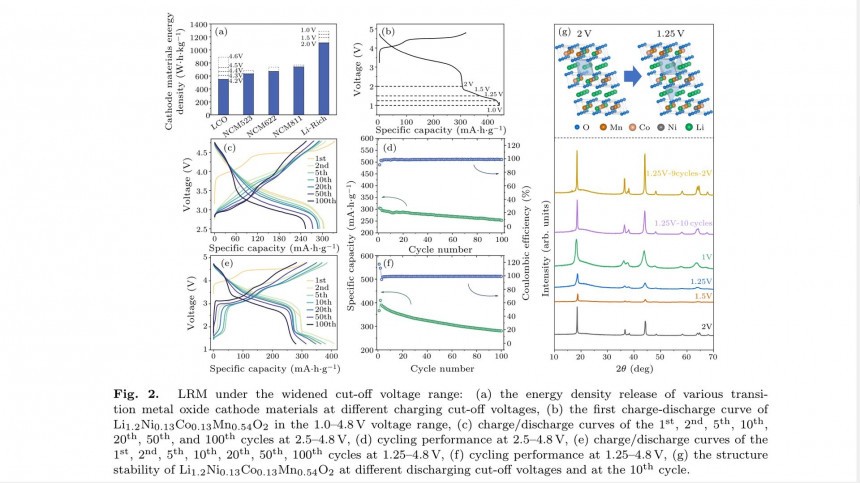

In this study, the most interesting aspect probably relates to how these scientists managed to create such a high-energy-density battery. Quan Li and his team used a lithium-rich manganese-based (LRM) cathode and lithium metal in the anode. They have also tried "organic (polyvinylidene difluoride, PVDF) and inorganic (Li1.3Al0.3Ti1.7(PO4)3, LATP) interface layers on the separator." PVDF was what showed more promising results.

Although it may seem like innovative chemistry, it is still ternary and has nickel, cobalt, and oxides (Li1.2 Ni0.13 Co0.13 Mn0.54 O2). Our Next Energy (ONE) is investing in chemistries without nickel and cobalt because it believes they are prone to thermal runaways (fires). Any battery with oxygen in its composition will have all it needs to burn until there is nothing left: it does not need air to keep feeding the blaze.

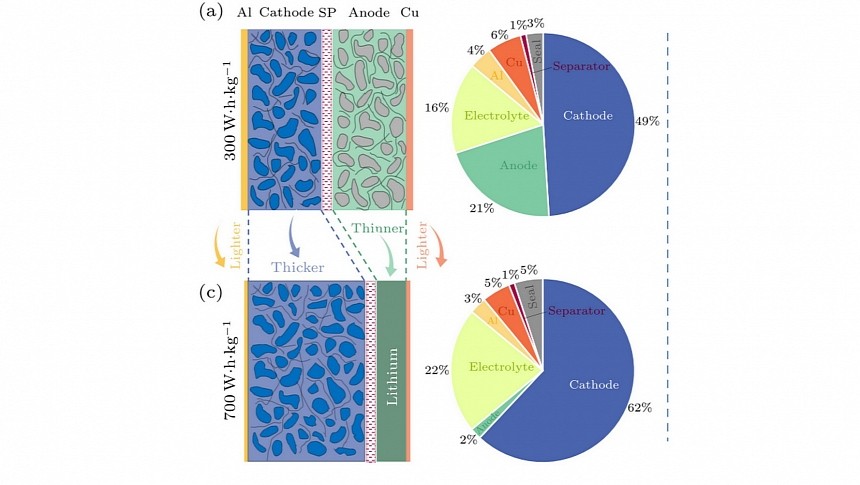

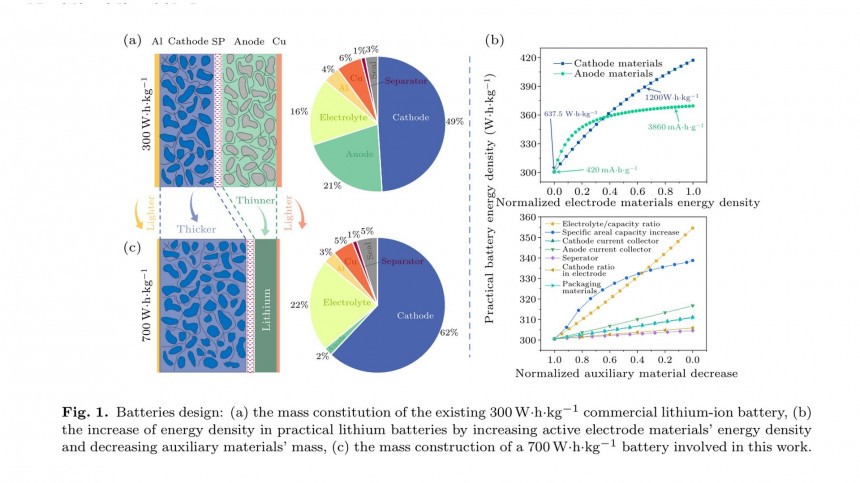

This high-energy-density cell also used advanced manufacturing techniques to have cathode-active substances represent more than 60% of the battery structure. The researchers used high-loading electrode preparation and lean electrolyte injection. Nowadays, the best ones have only around 48% of cathode-active material. That allowed the pouch cells to present "the highest gravimetric and volumetric energy density reported to date since the invention of lithium-ion batteries in the 1990s."

Supposing these cells were ready for production, they would help electric cars have either much lighter battery packs or much more range than current components do. According to Second Life EV Batteries, a Tesla Model S battery pack with 100 kWh weighs 625 kilograms (1,378 pounds). That is equivalent to 160 Wh/kg at the battery pack level. If the electric sedan used these 711.3 Wh/kg cells, its high-voltage accumulator would tip the scale at 140.6 kg (310 lb) for the same capacity (100 kWh) if we could find only cells in that structure. As that is not the case, the density at the battery pack level would certainly be lower, but it would still be great even if it were twice as heavy due to casing, wiring, cooling, and everything that adds weight to these components.

Unfortunately, these cells apparently were not tested for more than ten cycles. The researchers said that "despite a small capacity reduction in the second cycle, the battery capacity shows a high retention of 78.2% in the third cycle." Several BEV makers commit to replacing the battery pack under warranty if capacity drops below 70%. That shows how much more these new cells would have to improve if they were to reach mass production.

It may sound unfair to compare a scientific breakthrough like this one from the Beijing National Laboratory researchers and what a production cell offers – and it is. The commercial lithium-ion battery with the highest energy density nowadays is made by Beijing WeLion New Energy Technology, and it delivers 360 Wh/kg. That is just a bit more than half of what this lithium metal LRM cell provides. The idea here is precisely to stress how promising studies should be considered just as promises, not as something right around the corner to power BEVs.

At the same time, these scientific achievements also show how cell tech has to evolve before electric cars powered by battery packs truly become mainstream options. The energy density has to improve to reduce weight and improve efficiency, but that is just the beginning. Future battery packs also have to become either cheaper or much more durable. It is widely known – but poorly acknowledged – that cells have expiry dates and can only last for a given number of charging and discharging cycles.

As that is unlikely to change, perhaps the safest bet for BEVs is to have battery packs that are cheap to replace when the time comes or that work solely as a service, as Ample and NIO have been trying to implement. Just imagine what will happen to current BEVs when and if a breakthrough, such as having 711.3 Wh/kg, is finally ready for production: they will all become obsolete, either because they are too heavy or because of their lousy ranges. Will they be upgraded, or will they end up in junkyards? This should be our main concern.

In this study, the most interesting aspect probably relates to how these scientists managed to create such a high-energy-density battery. Quan Li and his team used a lithium-rich manganese-based (LRM) cathode and lithium metal in the anode. They have also tried "organic (polyvinylidene difluoride, PVDF) and inorganic (Li1.3Al0.3Ti1.7(PO4)3, LATP) interface layers on the separator." PVDF was what showed more promising results.

This high-energy-density cell also used advanced manufacturing techniques to have cathode-active substances represent more than 60% of the battery structure. The researchers used high-loading electrode preparation and lean electrolyte injection. Nowadays, the best ones have only around 48% of cathode-active material. That allowed the pouch cells to present "the highest gravimetric and volumetric energy density reported to date since the invention of lithium-ion batteries in the 1990s."

Unfortunately, these cells apparently were not tested for more than ten cycles. The researchers said that "despite a small capacity reduction in the second cycle, the battery capacity shows a high retention of 78.2% in the third cycle." Several BEV makers commit to replacing the battery pack under warranty if capacity drops below 70%. That shows how much more these new cells would have to improve if they were to reach mass production.

At the same time, these scientific achievements also show how cell tech has to evolve before electric cars powered by battery packs truly become mainstream options. The energy density has to improve to reduce weight and improve efficiency, but that is just the beginning. Future battery packs also have to become either cheaper or much more durable. It is widely known – but poorly acknowledged – that cells have expiry dates and can only last for a given number of charging and discharging cycles.