Transforming the up-and-down movement of a piston into a rotational one means losing some power due to friction, and that's why many engineers tried to create a rotary engine. But only one made it truly happen and applied it to cars: Felix Wankel.

All automakers tried to get the most out of their designed and built engines. Still, they were stuck with the same basic principle of the reciprocating, piston-powered design. But a few pioneers thought outside the box and created rotary units that didn't need connecting rods and crankshafts. One of these engineers was Felix Wankel.

The German genius was born in 1902. Two decades later, he became an active member of Hitler's NSDAP (Nazi, for short) party. Since his vision was different from the local leader, he was kicked out of the movement and jailed in 1933. But a good friend of Wankel, who was the economic adviser for the country's dictator, helped him to get out. In addition, the same friend, Wilhelm Keppler, financed Wankel's experimental workshop that developed rotary valves for WWII aircraft and torpedoes.

Since he was raised by a single mom, he couldn't afford to attend university. But his genius and his unique spacial vision helped him. He was very interested in reciprocating engines and tried to create something different. Thus, in 1929, he got his first patent for an invention. But that was only the beginning of what he was about to achieve in his long life.

The idea of a rotary engine has intrigued engineers and inventors since the beginning of the internal combustion engine's inception. The need for efficient and feasible technological inventions sparked another industrial revolution and brought the internal combustion engine into the 1900s spotlight. However, due to the rotary combustion engine's working principles, few engineers could overcome its challenges. In the end, only one car manufacturer achieved volume production: Mazda.

Wankel also noticed the radial engines that were already used by aviation. These were created by Felix Millet in 1888 and entered production in 1900. But, unfortunately, that type of engine had its flaws that couldn't be overcome. Because of that, the development of these power plants started to fade away after the '20s. But that didn't mean that with them, the rotary engine was dead.

After WWII, Felix Wankel was imprisoned by the French authorities and wasn't allowed to continue his work. Still, he was released after only a few months, and in 1951 he got funding from a German company. Thus, in 1957, he showed the first running prototype of his rotary engine, named DKM54, which produced just 21 PS (20,7 hp), and was created for the NSU Motorenwerke AG.

Six years later, in 1963, NSU unveiled the first production automobile fitted with the revolutionary rotary engine, which was already known as Wankel. However, things didn't stop there, and in 1967 NSU launched the RO80 model, which became the first German vehicle to receive the "Car Of The Year" award in Europe. The publicity brought by this engine was astonishing. At the same time, Mazda (who had already bought the rights to produce the Wankel engine) introduced the Cosmo. In addition, the Japanese automaker solved the vibration issues that the engine had and made it even better.

While the reciprocating (piston) engines were winning in Europe, Mazda continued to work on the rotary powerplant. As a result, it made it better and more powerful than Europeans could. Moreover, in 1991 Mazda became the first Japanese automaker to win the 24 Hours of Le Mans with a 787B prototype.

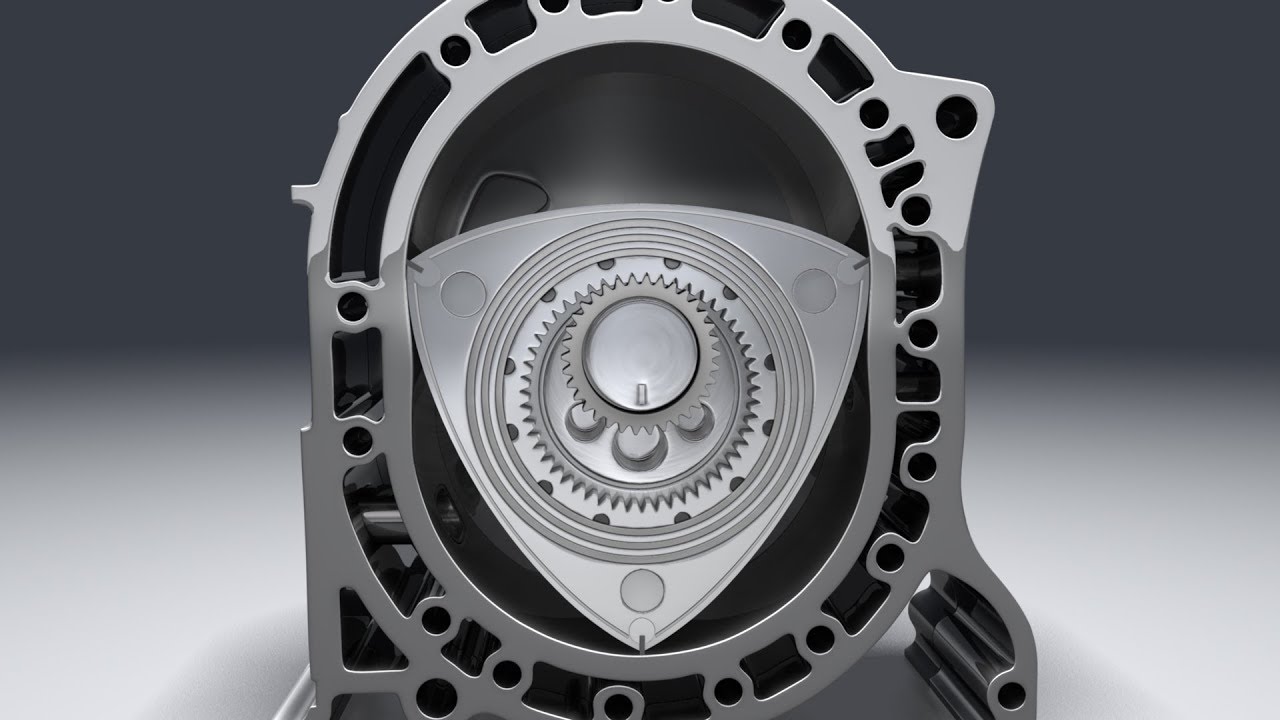

Even though it uses the same principle of converting pressure into rotating motion, it does that without the piston engine's vibrations and mechanical stress at high rotational speeds. Dr. Felix Wankel and his colleagues obtained the engine's housing design by completing the following steps: they first fixed an outer-toothed gear on a white sheet and interlocked it with a larger inner-toothed gear, with the ratio between the two gears being 2:3. Next, they attached an arm with a pen on the outside of the larger inner-toothed gear. When turning the inner-toothed gear on the small gear, the pen generated a cocoon-shaped trochoid curve.

The Wankel engine uses the explosion to push the side of the triangular rotor, which forces it to rotate. That means there's no need for any other parts to convert the pull-push movement into a circular one. Also, due to the special seals that cover the triangle's edges, there are no gaps between that moving part and the inner side of the housing, which will always be divided into three working chambers.

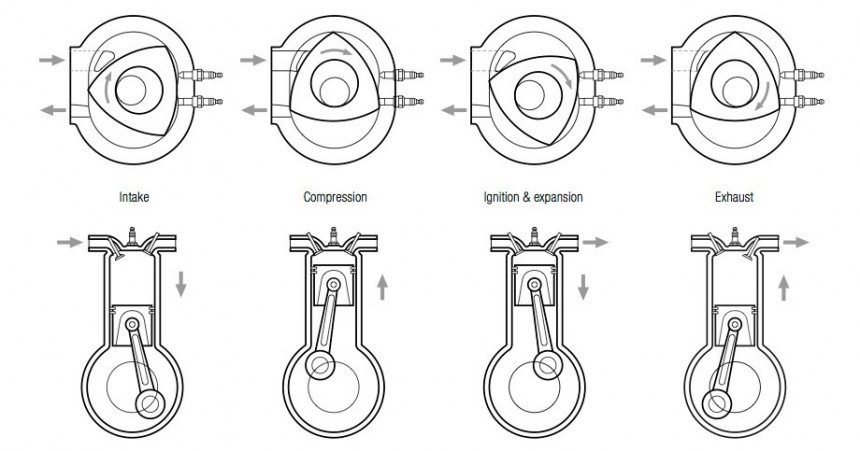

The admission is on one side of the housing, where the air and fuel mixture is sucked into the inside chamber by the rotor movement. Then, that mixture is compressed on the next phase, on the following side of the housing, and the ignition is initiated by two spark plugs. After the explosion, the gases expand into the next chamber, and they are released through a gap on the side of the housing, and no valves are needed.

Wankel's original design had an outer-toothed gear with 20 teeth, while the larger inner-toothed gear had 30 teeth. Due to this gear ratio, the rate of turning speed between the rotor and the shaft is defined as 1:3. This means that while the smaller gear makes a single revolution, the larger inner-toothed gear rotates three times. In addition, because the eccentric shaft, which is analogous to a crankshaft in a piston engine, is connected to the smaller toothed gear, it means that with the engine running at 3,000 rpm, the rotor will run at only 1,000 rpm. This not only means the rotary combustion engine runs smoother, but it also allows for achieving a higher redline.

The displacement volume of the rotary engine is usually expressed by the unit chamber volume and by the number of rotors (654cc x 2). The unit chamber volume represents the difference between the maximum volume and the minimum volume of a working chamber. At the same time, the compression ratio is defined as the ratio between the maximum and the minimum volume.

We recommend you take a closer look at the diagrams and Matt Rittman's 3D animation video below to better visualize and understand the Wankel engine's operating mode.

The second favorable trait of the rotary combustion engine is its flat torque curve characteristics throughout the whole speed range. Research results showed that using a two-rotor configuration, torque fluctuation during functioning was at the same level with an inline 6-cylinder reciprocating engine, while a three-rotor layout proved to run smoother than a V8 engine.

Other advantages of the rotary combustion engine are its simple structure, reliability, and durability. Because there are no pistons, rods, camshafts, timing belt, and rocker arms, the engine is easier to build and requires far fewer parts. Also, because it lacks these components, the Wankel engine is more reliable and durable under high-load operations. And remember, when the rotor engine runs at speeds of 8,000 rpm, the rotor (the largest part of the ensemble) turns at only one-third of that rate.

There are two significant problems with the Wankel engines. The most important one is the sealing systems from the triangular rotor's ends. While those seals shouldn't let the compressed mixture escape into the admission or the explosion chambers, they are not perfect. Due to that, unburned particles escape to the exhaust valve, leading to higher CO2 emissions.

That problem also leads to a second one: increased oil consumption. Ask any Mazda RX-7 or RX-8 owner if they have a pint of oil in their car, and they will admit it. Another problem with the Wankel engines is the high fuel consumption. Comparison tests showed that a Mazda RX-8 uses more fuel than a V8 powerplant with similar performance numbers. It's the price paid for lightweight and no vibrations.

But Mazda didn't give up on it and studied the possibility of using hydrogen instead of gasoline. That led to two concept cars, the RX-8 Hydrogen RE in 2003 and the Premacy Hydrogen RE in 2005. Thus, Felix Wankel's engine might still be part of Mazda's solution for a better environment. In 2021, the Japanese automaker announced that it would use a rotary powerplant as a generator for hybrid vehicles. If you combine hydrogen as a source of energy for the rotary engine and a battery pack, Mazda might have a solution that most other automakers ignored for decades. And it's based on a Wankel engine.

The German genius was born in 1902. Two decades later, he became an active member of Hitler's NSDAP (Nazi, for short) party. Since his vision was different from the local leader, he was kicked out of the movement and jailed in 1933. But a good friend of Wankel, who was the economic adviser for the country's dictator, helped him to get out. In addition, the same friend, Wilhelm Keppler, financed Wankel's experimental workshop that developed rotary valves for WWII aircraft and torpedoes.

Since he was raised by a single mom, he couldn't afford to attend university. But his genius and his unique spacial vision helped him. He was very interested in reciprocating engines and tried to create something different. Thus, in 1929, he got his first patent for an invention. But that was only the beginning of what he was about to achieve in his long life.

The idea of a rotary engine has intrigued engineers and inventors since the beginning of the internal combustion engine's inception. The need for efficient and feasible technological inventions sparked another industrial revolution and brought the internal combustion engine into the 1900s spotlight. However, due to the rotary combustion engine's working principles, few engineers could overcome its challenges. In the end, only one car manufacturer achieved volume production: Mazda.

After WWII, Felix Wankel was imprisoned by the French authorities and wasn't allowed to continue his work. Still, he was released after only a few months, and in 1951 he got funding from a German company. Thus, in 1957, he showed the first running prototype of his rotary engine, named DKM54, which produced just 21 PS (20,7 hp), and was created for the NSU Motorenwerke AG.

Six years later, in 1963, NSU unveiled the first production automobile fitted with the revolutionary rotary engine, which was already known as Wankel. However, things didn't stop there, and in 1967 NSU launched the RO80 model, which became the first German vehicle to receive the "Car Of The Year" award in Europe. The publicity brought by this engine was astonishing. At the same time, Mazda (who had already bought the rights to produce the Wankel engine) introduced the Cosmo. In addition, the Japanese automaker solved the vibration issues that the engine had and made it even better.

So How Does It Work

The rotary engine uses the same principles as an internal combustion engine with the Otto system. That means there are four strokes: admission – compression – ignition – evacuation. However, unlike the reciprocating engine that needs two strokes for each explosion, Wankel's engine only needs one. The brilliant idea is the design, completely different from the reciprocating one.Even though it uses the same principle of converting pressure into rotating motion, it does that without the piston engine's vibrations and mechanical stress at high rotational speeds. Dr. Felix Wankel and his colleagues obtained the engine's housing design by completing the following steps: they first fixed an outer-toothed gear on a white sheet and interlocked it with a larger inner-toothed gear, with the ratio between the two gears being 2:3. Next, they attached an arm with a pen on the outside of the larger inner-toothed gear. When turning the inner-toothed gear on the small gear, the pen generated a cocoon-shaped trochoid curve.

The Wankel engine uses the explosion to push the side of the triangular rotor, which forces it to rotate. That means there's no need for any other parts to convert the pull-push movement into a circular one. Also, due to the special seals that cover the triangle's edges, there are no gaps between that moving part and the inner side of the housing, which will always be divided into three working chambers.

Wankel's original design had an outer-toothed gear with 20 teeth, while the larger inner-toothed gear had 30 teeth. Due to this gear ratio, the rate of turning speed between the rotor and the shaft is defined as 1:3. This means that while the smaller gear makes a single revolution, the larger inner-toothed gear rotates three times. In addition, because the eccentric shaft, which is analogous to a crankshaft in a piston engine, is connected to the smaller toothed gear, it means that with the engine running at 3,000 rpm, the rotor will run at only 1,000 rpm. This not only means the rotary combustion engine runs smoother, but it also allows for achieving a higher redline.

The displacement volume of the rotary engine is usually expressed by the unit chamber volume and by the number of rotors (654cc x 2). The unit chamber volume represents the difference between the maximum volume and the minimum volume of a working chamber. At the same time, the compression ratio is defined as the ratio between the maximum and the minimum volume.

We recommend you take a closer look at the diagrams and Matt Rittman's 3D animation video below to better visualize and understand the Wankel engine's operating mode.

The Pros and Cons of the Wankel Engine

One of the most important advantages of a Wankel engine is its power-to-weight ratio, which is crucial for a sports car. In addition, its compact size allows automakers to create better-shaped vehicles, especially if the powerplant is mounted at the front. Its overall weight also allows for better mass distribution. Last but not least, it leaves more room for safety systems such as reinforcement struts and bars.The second favorable trait of the rotary combustion engine is its flat torque curve characteristics throughout the whole speed range. Research results showed that using a two-rotor configuration, torque fluctuation during functioning was at the same level with an inline 6-cylinder reciprocating engine, while a three-rotor layout proved to run smoother than a V8 engine.

Other advantages of the rotary combustion engine are its simple structure, reliability, and durability. Because there are no pistons, rods, camshafts, timing belt, and rocker arms, the engine is easier to build and requires far fewer parts. Also, because it lacks these components, the Wankel engine is more reliable and durable under high-load operations. And remember, when the rotor engine runs at speeds of 8,000 rpm, the rotor (the largest part of the ensemble) turns at only one-third of that rate.

There are two significant problems with the Wankel engines. The most important one is the sealing systems from the triangular rotor's ends. While those seals shouldn't let the compressed mixture escape into the admission or the explosion chambers, they are not perfect. Due to that, unburned particles escape to the exhaust valve, leading to higher CO2 emissions.

There might be a future for Wankel engines.

While other automakers ditched the Wankel engine for good, Mazda continued its study on it. The evolutions made by the company's engineers helped them win the coveted "International Engine of the Year" in 2003. But those research didn't stop there, and in 2007, the Japanese automaker unveiled the Taiki concept car at the Tokyo Auto Show, which was powered by a 300 PS (296 hp) twin-rotor Wankel rotary powerplant. But with the era of gasoline-powered ICEs, this type of propulsion might be doomed.But Mazda didn't give up on it and studied the possibility of using hydrogen instead of gasoline. That led to two concept cars, the RX-8 Hydrogen RE in 2003 and the Premacy Hydrogen RE in 2005. Thus, Felix Wankel's engine might still be part of Mazda's solution for a better environment. In 2021, the Japanese automaker announced that it would use a rotary powerplant as a generator for hybrid vehicles. If you combine hydrogen as a source of energy for the rotary engine and a battery pack, Mazda might have a solution that most other automakers ignored for decades. And it's based on a Wankel engine.