I'm no engineer, but I do happen to ride a bicycle nearly every day, and upon discovering this video on YouTube, I understood that there's a massive problem with the way our timeless two-wheelers are designed.

If you've ever ridden a bicycle, then you know very well what it takes to make one move. However, what if I told you that only half of our potential energy is being driven into our wheels? That's precisely the problem Works By Design tackles in a video they released.

The channel engineer(s) set out to create a system that takes full advantage of every drop of energy we exert while riding a bike. As a result, they've designed a machine with a weird setup, even removing the circular motion of our legs; it's replaced with a stepping action similar to the workouts we get from mountain climber equipment. To understand what the engineers have achieved, we need to look at how torque is generated during classic pedal operation.

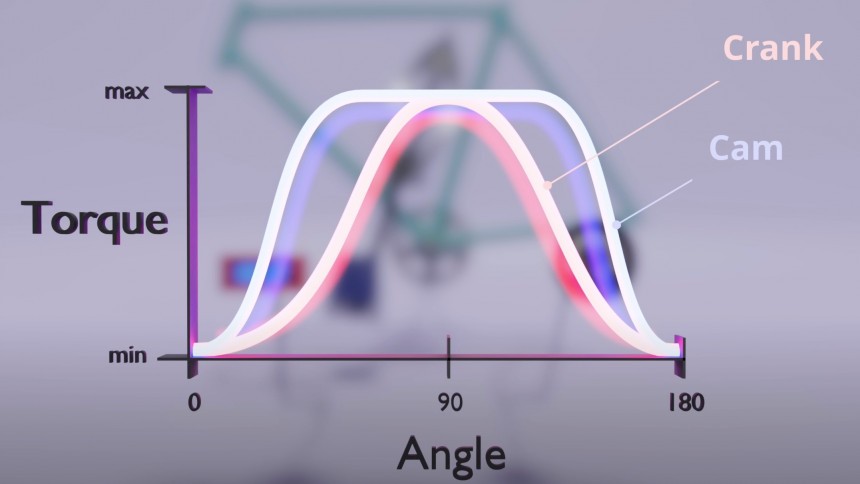

Whenever we press down on a bicycle's pedal - starting at the top of rotation - as we progress toward the bottom, we're only generating torque starting with the top until our crank reaches parallel to the ground. You can test this on any old bike by pedaling with just one foot.

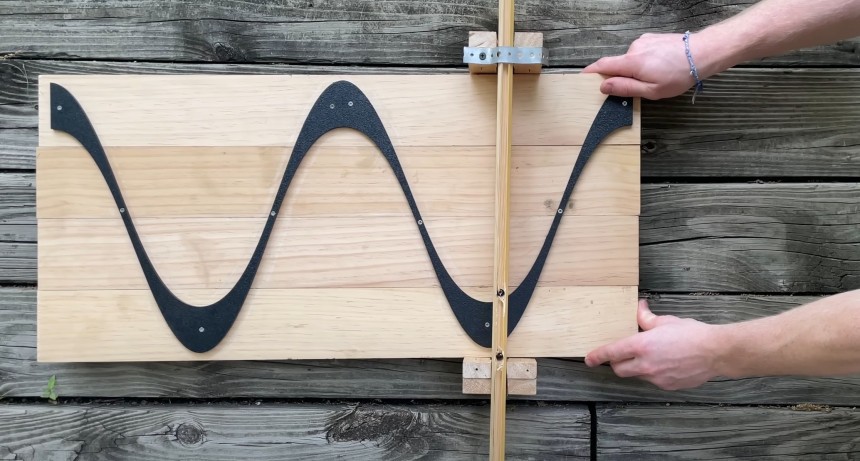

The remaining 90 degrees of rotation sees a decrease in torque of 100% toward the end of the movement. Once at the bottom of the cycle, the other leg would typically take over. In short, we're only generating power for around 50% of the time. In terms of energy flow, if put on paper, this action creates a flat sin wave, and that's the key to this whole experiment.

This is where Work By Design comes in; they set out to create a system that continuously generates and captures as much power and torque as possible, and as you'd expect, all that starts off with nothing more than an old bicycle frame.

With a bit of 3D scanning and other engineering software, the minds behind the project began to work out precisely what they wanted. By the looks of things, they've created a central cylinder with the flat sin configuration wrapped onto it, which a set of guides or rollers would ultimately follow.

But, to do this, the engineers had to redesign the pedaling motion we typically follow, in the process, giving rise to two cams that move up and down in an alternating sequence. As they do, the rollers move along the flat sin path and cause the cylinder to rotate.

Why this setup? With nothing but a vertical motion for each leg (the cam), in which the rollers follow precisely 1/2 of the flat sin's path, Works By Design was able to capture 50% of energy output with just 1/2 a cycle of a cam. The other 50% is generated by the other leg, giving us the ability to maintain torque output on a plateau configuration rather than the flat sin wave. Again, I'm no engineer or math wiz, so this is a bit tricky to explain, but it works.

Now, that system forces the central drive to rotate as a cyclist "pedals." but how do we transfer that circular motion into a rear wheel? This is where a set of miter gears come in, allowing the horizontal rotation of the drive to be transferred into a vertical one, at which point, a chain is added to the other end of the gear.

Once the chain is in place, the rest of the feat is only down to a few minor modifications here and there. Maintaining tension on the chain is one aspect that needed a tad of attention, too. You can see more of the stages this crew went through in the video below.

As for the last few moments of the video, we're shown that this thing actually works well enough to keep the rider upright and moving forward like on any other bicycle. Sure, we can see the rider struggling a bit with the whole stepper motion, but it doesn't look like anyone was hurt in the making of this video.

There's just one thing I'd like to point out about the design and the output: in theory, there should be 100% power transfer into the rear wheel, but as we can see, the peaks and troughs of the cam drive still cause the rider to catch a bit of a breather, if you will; for a moment, there's a point of pause before the other leg muscles activate for the next downstroke.

So, why aren't Tour de France riders rocking bicycles with such a setup? Did you see that massive framework that had to be devised for this to work? That's got to be a few extra pounds, and we haven't even tackled aerodynamics yet. Then there's the matter of having to pedal non-stop as the miter gears require the rider to continuously move their legs, fixed-gear style.

I also need to point out that those moments of "rest" conventional drivetrains offer are one of the main reasons why we can even ride bikes for hundreds of miles at a time. Yes, what Works By Design has achieved here is a more efficient setup, but is it better than what we currently have? Feel free to comment below.

The channel engineer(s) set out to create a system that takes full advantage of every drop of energy we exert while riding a bike. As a result, they've designed a machine with a weird setup, even removing the circular motion of our legs; it's replaced with a stepping action similar to the workouts we get from mountain climber equipment. To understand what the engineers have achieved, we need to look at how torque is generated during classic pedal operation.

Whenever we press down on a bicycle's pedal - starting at the top of rotation - as we progress toward the bottom, we're only generating torque starting with the top until our crank reaches parallel to the ground. You can test this on any old bike by pedaling with just one foot.

The remaining 90 degrees of rotation sees a decrease in torque of 100% toward the end of the movement. Once at the bottom of the cycle, the other leg would typically take over. In short, we're only generating power for around 50% of the time. In terms of energy flow, if put on paper, this action creates a flat sin wave, and that's the key to this whole experiment.

With a bit of 3D scanning and other engineering software, the minds behind the project began to work out precisely what they wanted. By the looks of things, they've created a central cylinder with the flat sin configuration wrapped onto it, which a set of guides or rollers would ultimately follow.

But, to do this, the engineers had to redesign the pedaling motion we typically follow, in the process, giving rise to two cams that move up and down in an alternating sequence. As they do, the rollers move along the flat sin path and cause the cylinder to rotate.

Why this setup? With nothing but a vertical motion for each leg (the cam), in which the rollers follow precisely 1/2 of the flat sin's path, Works By Design was able to capture 50% of energy output with just 1/2 a cycle of a cam. The other 50% is generated by the other leg, giving us the ability to maintain torque output on a plateau configuration rather than the flat sin wave. Again, I'm no engineer or math wiz, so this is a bit tricky to explain, but it works.

Once the chain is in place, the rest of the feat is only down to a few minor modifications here and there. Maintaining tension on the chain is one aspect that needed a tad of attention, too. You can see more of the stages this crew went through in the video below.

As for the last few moments of the video, we're shown that this thing actually works well enough to keep the rider upright and moving forward like on any other bicycle. Sure, we can see the rider struggling a bit with the whole stepper motion, but it doesn't look like anyone was hurt in the making of this video.

So, why aren't Tour de France riders rocking bicycles with such a setup? Did you see that massive framework that had to be devised for this to work? That's got to be a few extra pounds, and we haven't even tackled aerodynamics yet. Then there's the matter of having to pedal non-stop as the miter gears require the rider to continuously move their legs, fixed-gear style.

I also need to point out that those moments of "rest" conventional drivetrains offer are one of the main reasons why we can even ride bikes for hundreds of miles at a time. Yes, what Works By Design has achieved here is a more efficient setup, but is it better than what we currently have? Feel free to comment below.