Over ten million euros ($12.3 million) will be invested by German auto group BMW in the creation of the new Additive Manufacturing Campus, a facility north of Munich where 3D printing technologies will be created and tested.

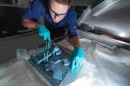

Seen as a way to make car parts both cheaper and faster, 3D printing has already been used by BMW to produce parts for the i8 Roadster. By doing so, the Germans claim they became the first automotive company to 3D-print a production run of several thousand metal parts.

BMW says the new campus will concentrate the entire scope of its efforts in this field, from research to production. Printing in plastics and metals will go under review, with the goal of creating both the technology and the process chain required in this new field.

The Oberschleissheim center will also become a pilot plant for the production of 3D-printed parts. Its assembly lines would roll off solutions for prototype construction, series production, and customized parts.

"The 3D printers that are currently operating across our production network represent the first step towards local part production,” said Jens Ertel, the head of the new BMW facility.

“Going forward, we could well imagine integrating it more fully into local production structures to allow small production runs, country-specific editions and customizable components – provided it represents a profitable solution.”

This is not the first step BMW is taking towards the creation of an entirely new production process. Two years ago, through BMW i Ventures, it invested in U.S. start-up Carbon, which specializes in the production of parts with high-quality surfaces.

In 2017, the group poured money into start-up Desktop Metal. The company, which does business in the additive manufacturing of metal components, will become a collaborator of the new Additive Manufacturing Centre.

BMW did not say when the new center will be open for business.

BMW says the new campus will concentrate the entire scope of its efforts in this field, from research to production. Printing in plastics and metals will go under review, with the goal of creating both the technology and the process chain required in this new field.

The Oberschleissheim center will also become a pilot plant for the production of 3D-printed parts. Its assembly lines would roll off solutions for prototype construction, series production, and customized parts.

"The 3D printers that are currently operating across our production network represent the first step towards local part production,” said Jens Ertel, the head of the new BMW facility.

“Going forward, we could well imagine integrating it more fully into local production structures to allow small production runs, country-specific editions and customizable components – provided it represents a profitable solution.”

This is not the first step BMW is taking towards the creation of an entirely new production process. Two years ago, through BMW i Ventures, it invested in U.S. start-up Carbon, which specializes in the production of parts with high-quality surfaces.

In 2017, the group poured money into start-up Desktop Metal. The company, which does business in the additive manufacturing of metal components, will become a collaborator of the new Additive Manufacturing Centre.

BMW did not say when the new center will be open for business.