When the auto industry was young and 20-liter long-nosed inefficient gas-guzzler cars were starting to raise the noise level in major towns, the small workshops manufacturing them manually took a dozen men and over 12 hours to take one out through the gates.

Then, 100 years ago today, Henry Ford and his team at Highland Park assembly plant launched the world’s greatest manufacturing contribution - the first moving assembly line. The revolutionary process broke down the Model T’s production into 84 distinct steps, performed by groups of workers, while a rope pulled the vehicle down the line. This procedure dropped the assembly time for a single vehicle from 12 hours to about 90 minutes.

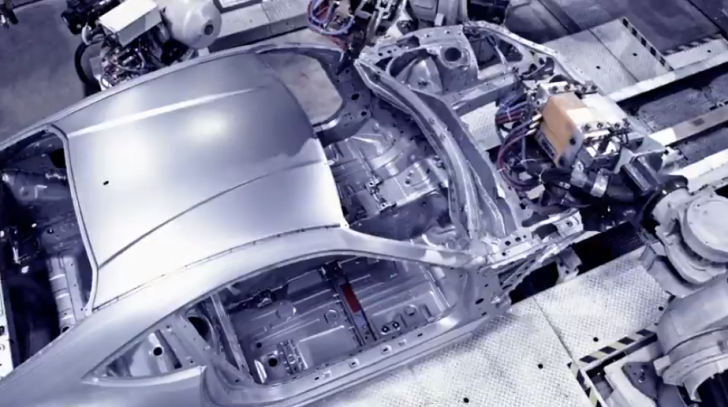

Fast forward to 2013, to Toyota’s GT 86 assembly plant in Gunma, Japan, and you can see how much that process has evolved, where precise machinery took the whole work of turning thousands of parts into one of the greatest sportscars around.

Get a glimpse at the GT 86’s production process in the cool montage bellow.

Fast forward to 2013, to Toyota’s GT 86 assembly plant in Gunma, Japan, and you can see how much that process has evolved, where precise machinery took the whole work of turning thousands of parts into one of the greatest sportscars around.

Get a glimpse at the GT 86’s production process in the cool montage bellow.