Tesla aims to cut production costs in half with its next-generation model that will be assembled at Giga Mexico. According to a physics engineer involved with Tesla, the EV maker will employ a new production technique called "fluid cell sheet metal hydroforming" to boost production efficiency.

Although investors weren't impressed after Tesla's Investor Day, many things discussed at the event were nothing short of groundbreaking. If Tesla gets it right, Tesla's revolutionary manufacturing process called "Unboxed Vehicle" deserves a special place in automotive history. This is akin to a new manufacturing revolution, enabling a massive speed-up of the car production line by eliminating many redundant steps. Still, Tesla has more aces up its sleeve that would allow it to sell the upcoming mass-market EV at a killer price.

The conference was light on details, with a couple of slides showing how Tesla intends to assemble the parts of its vehicles only once. At the same time, the car is broken in several assemblies, allowing more people to work simultaneously. There seems to be more to this manufacturing process than Tesla has revealed. Alex (@ajtourville), a physics engineer who seems to know what he's talking about, says Tesla is preparing a new production technique for the external body panels.

Tesla developed several advanced manufacturing processes that are largely credited for Tesla's profitability compared to traditional carmakers. Tesla vastly simplified the car body design with the use of megacastings. The die-cast underbody panels replace hundreds of individual components and make complex welding unnecessary. It also introduced the structural battery packs, connecting the front and rear megacasting into one big chassis part.

Finally, Tesla achieved another breakthrough with Cybertruck's stainless steel exoskeleton. The Cybertruck body panels are strong enough that Tesla doesn't need to use other structural parts. The best part is that it doesn't need to paint them either since they are made of stainless steel. Instead, the panels can be laser-engraved, creating unique patterns. According to Alex, Tesla might use a new production technique to form the body panels, called fluid cell sheet metal hydroforming.

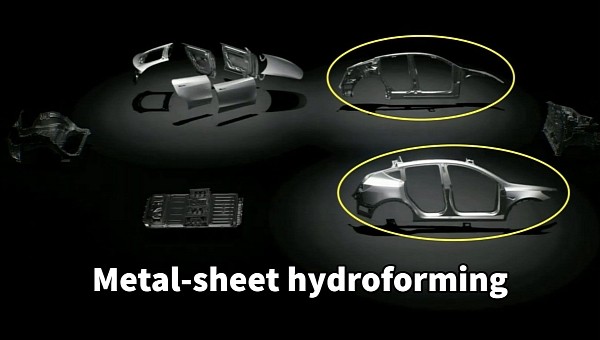

Unlike metal stamping, hydroforming uses a single mold and applies pressure using a high-pressure hydraulic fluid to shape the metal. This technique produces lighter, stronger parts with complex shapes and precise dimensions. There are marked advantages to using the new method, with accuracy and consistency being the most important. The technique can also realize single-piece side body panels, essential for the unboxed-vehicle manufacturing process.

By combining all these techniques, Tesla is confident it can slash production costs in half compared to the Model 3/Y. The EV maker will also use structural adhesives to assemble all the parts, which it already does with the Model Y megacastings. Adhesives are a better alternative to rivets and spot welding, ensuring higher rigidity and passive safety.

The conference was light on details, with a couple of slides showing how Tesla intends to assemble the parts of its vehicles only once. At the same time, the car is broken in several assemblies, allowing more people to work simultaneously. There seems to be more to this manufacturing process than Tesla has revealed. Alex (@ajtourville), a physics engineer who seems to know what he's talking about, says Tesla is preparing a new production technique for the external body panels.

Tesla developed several advanced manufacturing processes that are largely credited for Tesla's profitability compared to traditional carmakers. Tesla vastly simplified the car body design with the use of megacastings. The die-cast underbody panels replace hundreds of individual components and make complex welding unnecessary. It also introduced the structural battery packs, connecting the front and rear megacasting into one big chassis part.

Finally, Tesla achieved another breakthrough with Cybertruck's stainless steel exoskeleton. The Cybertruck body panels are strong enough that Tesla doesn't need to use other structural parts. The best part is that it doesn't need to paint them either since they are made of stainless steel. Instead, the panels can be laser-engraved, creating unique patterns. According to Alex, Tesla might use a new production technique to form the body panels, called fluid cell sheet metal hydroforming.

Unlike metal stamping, hydroforming uses a single mold and applies pressure using a high-pressure hydraulic fluid to shape the metal. This technique produces lighter, stronger parts with complex shapes and precise dimensions. There are marked advantages to using the new method, with accuracy and consistency being the most important. The technique can also realize single-piece side body panels, essential for the unboxed-vehicle manufacturing process.

By combining all these techniques, Tesla is confident it can slash production costs in half compared to the Model 3/Y. The EV maker will also use structural adhesives to assemble all the parts, which it already does with the Model Y megacastings. Adhesives are a better alternative to rivets and spot welding, ensuring higher rigidity and passive safety.

Fluid cell sheet metal hydroforming seems like something Tesla could take to the next level for mass manufacturing:

— ALEX (@ajtourville) March 19, 2023

→ Low tooling cost (1 die per part instead of 2)

→ Short setup times

→ One-operation forming

→ Multiple parts per cycle

→ High accuracy & consistency

→ Etc.