Everybody is aware that battery manufacturing has its toll on the environment. This is the main argument of EV detractors trying to defend internal combustion engines or hydrogen and e-fuels. Now, two more studies pour gasoline on the fire (pun intended!), blaming the battery industry for collateral severe damage to human health and the environment.

When in use, electric cars do slash emissions by a pretty significant margin compared to ICE cars. Unfortunately, there's the inconvenient truth of battery manufacturing-related pollution.

Although this is a real issue, it tends to be overestimated by many, resulting in many conflicts between proponents of battery tech and those who bet on alternatives. These conflicts tend to have unexpected influences on policymakers and investors.

Experts consider it "a groundbreaking study" providing new insights into "potentially dangerous concentrations of toxic waste." At this point, please notice some terms: "could," "estimated," and "potentially." Which I'm sure you won't find in those social media short inflammatory posts on the subject.

The authors state that this comprehensive study is a first-of-its-kind tool meant to help "governments, environmental regulators, the mining industry and local communities […] to assess the offsite and downstream impacts of mining on ecosystem and human health."

Nevertheless, this study was necessary because of the "growing demand for metals and minerals to feed the demands of the green energy transition." Too bad similar studies weren't conducted in previous decades. After all, the mining industry is several hundred years old; it's hard to believe its impact wasn't considered important until "the green energy transition."

But don't mind my electrohead subversive statements; let's see some numbers and facts. Because they simply can't be overlooked.

There are two leading causes of contamination. Firstly, transporting raw materials from the mining site and depositing them along river channels and floodplains, waiting to be loaded into trains or ships, causes leakage of hazardous metals into water. Secondly, the tailings storage facilities for mine waste are even more harmful because of the extended periods they are kept in one place, thus favoring leakage of toxic materials into the soil.

From time to time, there are all kinds of accidents happening. For instance, in January 2019, the Vale tailings dam rupture in Brumadinho, Minas Gerais, Brazil, released around 12 million cubic meters of tailings. Two hundred seventy people died there, while at least 27 elements of toxic metals were later discovered in the river sediments. To give you a perspective, severe cadmium concentrations were found some 200 miles / 300 km downstream from the mine site.

The study revealed that "long-term discharge of mining waste into rivers is almost 50 times greater than the number directly affected by acute tailings dam failures." Researchers concluded that contamination affects approximately 300,000 miles / 480,000 km of river channels worldwide and 63,000 square miles / 164,000 square km of floodplains.

Based on conservative estimates – because of a lack of available demographic data for several countries – researchers believe that more than 23 million people live in those potentially affected areas. There are also 5.72 million livestock and over 25,000 square miles / 65,000 square km of irrigated land to consider.

So, based on this study, researchers consider that now it's up to industry and regulatory agencies to develop better strategies to avoid "the threat posed to people, ecosystems, and the wider environment from metal mining activity."

We're still waiting to see if the absolute need for sustainability won't actually become a brake for the transition to green technologies. Because the "batteries harm the environment!" assertion could be more harmful to tackling climate change than the estimated data of this study. But wait, there's more to batteries.

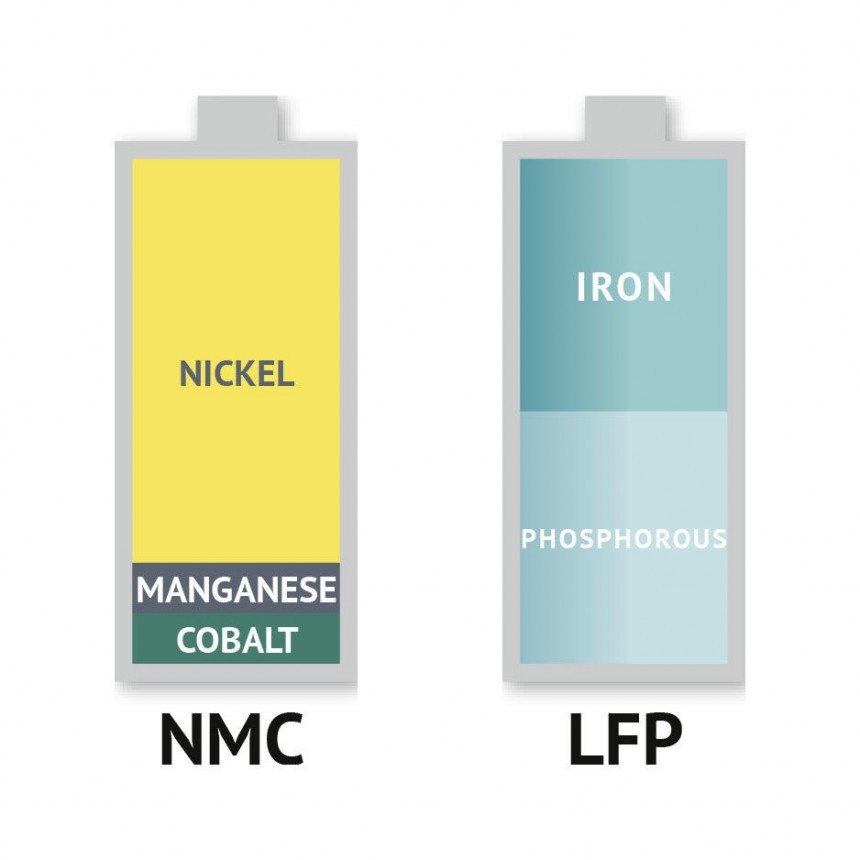

No matter who's the best fortune teller, this means considerable pressure on the mining industry and the raw materials resources. Currently, the most popular recipe for lithium-ion batteries is the nickel-cobalt-manganese mix (NCM).

Of course, cobalt makes everybody think about Congo's slavery and child labor due to the unregulated artisanal mining. The Democratic Republic of Congo accounts for 70% of global production, while cobalt mining is considered one of the worst regarding environmental issues.

That's why, some years ago, the battery industry came up with a viable alternative: lithium-iron-phosphate cells (LFP). China is the leading producer of this kind of less-environmental-unfriendly type of battery.

You may have heard that CATL – the biggest battery supplier in the world with more than 30% market share – is providing Tesla and NIO with LFP batteries. More recently, Korean LG Chem – the second biggest battery supplier in the world – announced a partnership with the Chinese never-heard-of Huayou Group to build an LFP plant in Morocco, North Africa.

In short, the global LFP battery market is projected to grow from around $13 billion / €12.2 billion in 2022 to more than $35 billion / €33 billion by 2030. Unless Benchmark's interesting new study regarding LFP carbon footprint won't become another weapon for the naysayers.

The cobalt content in EV batteries can be halved by 2030 thanks to improved pack assembly techniques. Two of the most appealing are the cell-to-pack (C2P) technology – which increases the energy density of cobalt-free LFP batteries – and the high-nickel NMC cathodes – which sharply decrease the need for cobalt.

Now it's time for Benchmark's "hold my beer" moment. According to new data from Benchmark's Battery Emissions Analyzer, LFP and high-nickel NMC cells can have a higher carbon footprint than mid-nickel NMC cells. "Can have" is for "in certain conditions," so you should take it with a grain of salt.

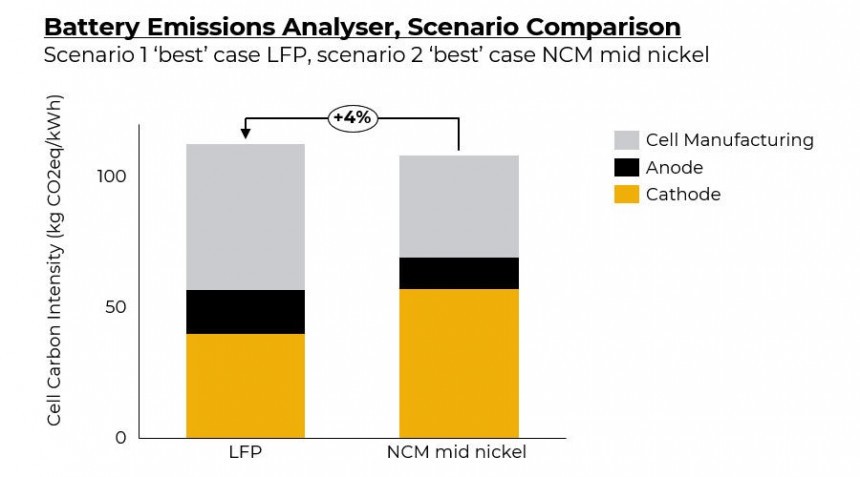

At present, in the best-case scenario for producing both LFP and mid-nickel NCM cells, the cobalt-free cells prove 4% more carbon-intensive. Despite lacking cobalt and nickel, LFP cells require more active and inactive materials than NCM cells on a kWh basis due to their lower energy density.

However, the slight increase in emissions is offset by LFP batteries' cost advantage and more extended durability, which lowers their lifetime emissions footprint. Moreover, comparing the best- and worst-case scenarios for the three types of cells (LFP, mid-nickel NCM, and high-nickel NCM), LFPs are by far the best choice regarding carbon intensity.

In the case of NCM cells, researchers also found a big difference in carbon intensity depending on the nickel-sourcing technology. Using the RKEF processing (Rotary Kiln Electric Furnace) results in a 58% carbon emissions increase than using the HPAL processing (High-Pressure Acid Leaching). This is an essential hint for both battery manufacturers and policymakers.

For decades, environmentalists have fought fierce battles with mining companies over the dramatic impact mining activities and heavy metals have on people and the environment. Over the years, the mining industry acknowledged the issues it provoked and slightly improved its processes.

Today, sustainability is a must. But simply pointing the finger at this sector – which indeed could impact the health and lives of more than 20 million people – is merely misleading when ignoring the more than 10 million premature deaths caused every year by the fossil fuels industry.

It may sound cynical, but we've come to the point of a tough choice: do we agree to sacrifice a dozen people now to ensure the survival and thriving of billions in the following decades? Or do we jeopardize everyone's future on this planet by choosing not to transition from a fossil fuel-based economy to a green one because of inherent collateral damages for the moment?

As for me, I'm only curious now about what bits of information from these studies will get to social and mainstream media and how they will impact the general public's opinion on electromobility. Or on its perils.

Although this is a real issue, it tends to be overestimated by many, resulting in many conflicts between proponents of battery tech and those who bet on alternatives. These conflicts tend to have unexpected influences on policymakers and investors.

The toll for mining for raw materials? 23 million souls. Presumably

A recent study published in Science warns that metal mining contamination on rivers and floodplains could affect an estimated 23 million people worldwide. The study was compiled by an international team of researchers led by professors from the Lincoln Centre for Water and Planetary Health at the University of Lincoln, UK.Experts consider it "a groundbreaking study" providing new insights into "potentially dangerous concentrations of toxic waste." At this point, please notice some terms: "could," "estimated," and "potentially." Which I'm sure you won't find in those social media short inflammatory posts on the subject.

The authors state that this comprehensive study is a first-of-its-kind tool meant to help "governments, environmental regulators, the mining industry and local communities […] to assess the offsite and downstream impacts of mining on ecosystem and human health."

But don't mind my electrohead subversive statements; let's see some numbers and facts. Because they simply can't be overlooked.

The risks posed by poorly managed mining activities

The study used a global database of 185,000 metal mines worldwide. At the same time, researchers used new methods to model contamination from the most popular hazardous metals, such as lead, zinc, copper, and arsenic. Humans become exposed through skin contact, accidental ingestion, inhalation of contaminated dust, or consumption of contaminated water and food grown on contaminated soils.There are two leading causes of contamination. Firstly, transporting raw materials from the mining site and depositing them along river channels and floodplains, waiting to be loaded into trains or ships, causes leakage of hazardous metals into water. Secondly, the tailings storage facilities for mine waste are even more harmful because of the extended periods they are kept in one place, thus favoring leakage of toxic materials into the soil.

From time to time, there are all kinds of accidents happening. For instance, in January 2019, the Vale tailings dam rupture in Brumadinho, Minas Gerais, Brazil, released around 12 million cubic meters of tailings. Two hundred seventy people died there, while at least 27 elements of toxic metals were later discovered in the river sediments. To give you a perspective, severe cadmium concentrations were found some 200 miles / 300 km downstream from the mine site.

The study revealed that "long-term discharge of mining waste into rivers is almost 50 times greater than the number directly affected by acute tailings dam failures." Researchers concluded that contamination affects approximately 300,000 miles / 480,000 km of river channels worldwide and 63,000 square miles / 164,000 square km of floodplains.

Based on conservative estimates – because of a lack of available demographic data for several countries – researchers believe that more than 23 million people live in those potentially affected areas. There are also 5.72 million livestock and over 25,000 square miles / 65,000 square km of irrigated land to consider.

We're still waiting to see if the absolute need for sustainability won't actually become a brake for the transition to green technologies. Because the "batteries harm the environment!" assertion could be more harmful to tackling climate change than the estimated data of this study. But wait, there's more to batteries.

Due to cobalt issues, LFP batteries are rising

The most recent estimates on global EV battery production by 2030 come from Benchmark Mineral Intelligence Agency and ABI Research technology intelligence firm. Benchmark's latest estimates state that lithium-ion battery capacity is set to grow four-fold by the decade's end, while ABI Research is more optimistic, estimating a six-fold increase.No matter who's the best fortune teller, this means considerable pressure on the mining industry and the raw materials resources. Currently, the most popular recipe for lithium-ion batteries is the nickel-cobalt-manganese mix (NCM).

Of course, cobalt makes everybody think about Congo's slavery and child labor due to the unregulated artisanal mining. The Democratic Republic of Congo accounts for 70% of global production, while cobalt mining is considered one of the worst regarding environmental issues.

You may have heard that CATL – the biggest battery supplier in the world with more than 30% market share – is providing Tesla and NIO with LFP batteries. More recently, Korean LG Chem – the second biggest battery supplier in the world – announced a partnership with the Chinese never-heard-of Huayou Group to build an LFP plant in Morocco, North Africa.

In short, the global LFP battery market is projected to grow from around $13 billion / €12.2 billion in 2022 to more than $35 billion / €33 billion by 2030. Unless Benchmark's interesting new study regarding LFP carbon footprint won't become another weapon for the naysayers.

Is LFP the new king? Then it must have a dark side

According to ABI Research, "solid-state batteries are unlikely to significantly impact this decade." Instead, the rapid increase of global EV battery production will most likely be based on the "evolutionary improvements on existing lithium-ion battery technology."The cobalt content in EV batteries can be halved by 2030 thanks to improved pack assembly techniques. Two of the most appealing are the cell-to-pack (C2P) technology – which increases the energy density of cobalt-free LFP batteries – and the high-nickel NMC cathodes – which sharply decrease the need for cobalt.

Now it's time for Benchmark's "hold my beer" moment. According to new data from Benchmark's Battery Emissions Analyzer, LFP and high-nickel NMC cells can have a higher carbon footprint than mid-nickel NMC cells. "Can have" is for "in certain conditions," so you should take it with a grain of salt.

At present, in the best-case scenario for producing both LFP and mid-nickel NCM cells, the cobalt-free cells prove 4% more carbon-intensive. Despite lacking cobalt and nickel, LFP cells require more active and inactive materials than NCM cells on a kWh basis due to their lower energy density.

In the case of NCM cells, researchers also found a big difference in carbon intensity depending on the nickel-sourcing technology. Using the RKEF processing (Rotary Kiln Electric Furnace) results in a 58% carbon emissions increase than using the HPAL processing (High-Pressure Acid Leaching). This is an essential hint for both battery manufacturers and policymakers.

Almost a big fuss over nothing

Taken out of context, the conclusions of these two studies may shed a grim picture of the battery sector.For decades, environmentalists have fought fierce battles with mining companies over the dramatic impact mining activities and heavy metals have on people and the environment. Over the years, the mining industry acknowledged the issues it provoked and slightly improved its processes.

Today, sustainability is a must. But simply pointing the finger at this sector – which indeed could impact the health and lives of more than 20 million people – is merely misleading when ignoring the more than 10 million premature deaths caused every year by the fossil fuels industry.

It may sound cynical, but we've come to the point of a tough choice: do we agree to sacrifice a dozen people now to ensure the survival and thriving of billions in the following decades? Or do we jeopardize everyone's future on this planet by choosing not to transition from a fossil fuel-based economy to a green one because of inherent collateral damages for the moment?

As for me, I'm only curious now about what bits of information from these studies will get to social and mainstream media and how they will impact the general public's opinion on electromobility. Or on its perils.