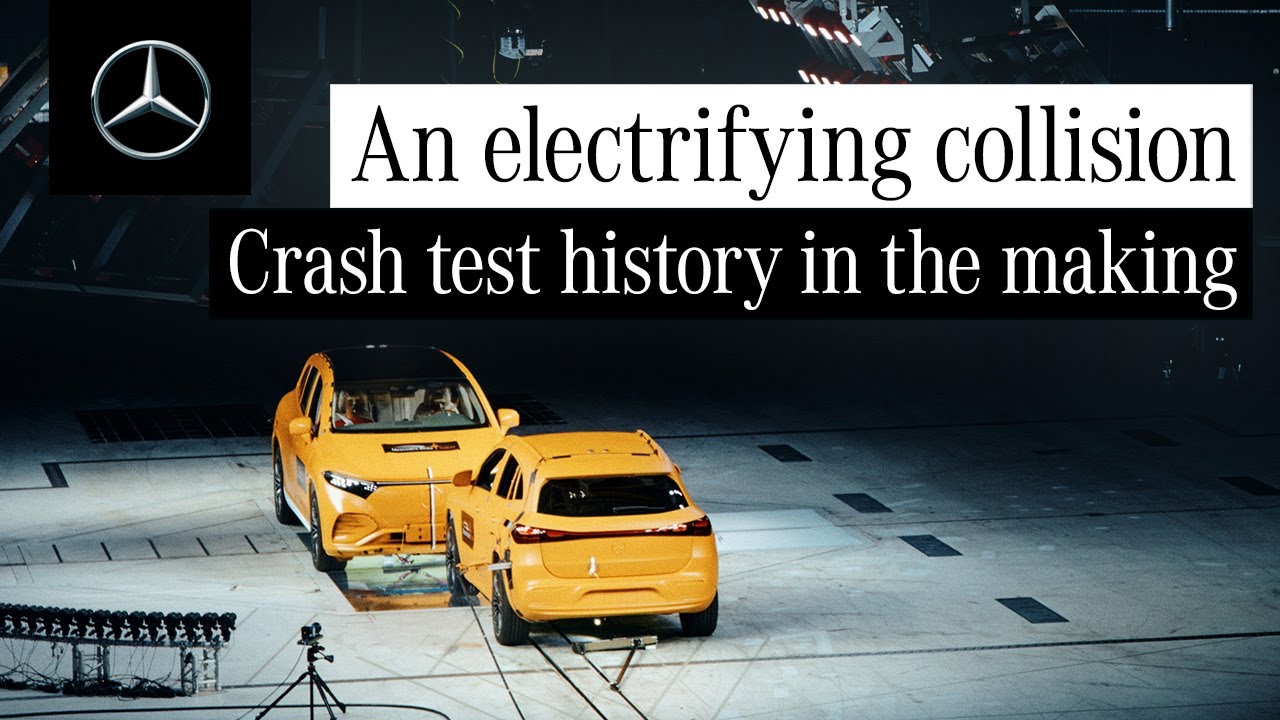

Mercedes-Benz has just become the world's first automaker which publicly conducted a crash test between two electric cars. An EQA and an EQS SUV collided head-on, each traveling at 35 mph.

The German carmaker goes above and beyond the legal requirements in terms of safety. Euro NCAP requires the use of a 1,400-kilogram (3,086-pound) trolley sporting an aluminum honeycomb barrier, specifically designed to replicate the front end of another vehicle. They are supposed to collide at 50 kph (31 mph), a scenario that can happen, for instance, during an overtaking maneuver.

But Mercedes-Benz went further and used two real cars, the EQA crossover and the EQS SUV, weighing 2.2 and 3 tons, respectively. And instead of the required speed, the two of them traveled toward each other at 56 kph (35 mph). This translates into higher overall crash energy compared to what the regulations demand.

The real-life crash confirmed what the numerous computer simulations had previously shown. After the crash, both cars look terrible. The deformation might seem alarming for those who are not experts. However, the Mercedes-Benz engineers noticed that both cars effectively absorbed the energy of the collision by deforming like that and reduced the forces applied on the occupants.

And, the most important part of all, the passenger safety cell of both electric cars remained intact, and doors could still be opened. In an emergency situation, the opening of doors by the first responders and the rescue personnel might be a matter of life and death.

To be able to evaluate the aftermath of the crash on the occupants, the team installed up to 150 measuring points per dummy. According to the engineers, the risk of the dummies sustaining what would be fatal injuries in the case of a human occupant is very low. All the safety equipment on board the cars worked as intended. Airbags deployed, and belt tensioners with belt force limiters kept the dummies in place.

The crumple zones acted correctly in the frontal collision and did the job they were designed for. They were practically destroyed, but kept everything else safe.

The engineers also noted the high-voltage system of the EQA and the EQS SUV switched off automatically on the impact, while batteries and high-voltage components did not sustain any damage at all. That is because the carmaker developed a multi-stage protection concept for its electric cars, with separate positive and negative wiring, as well as self-monitoring high-voltage system, which automatically switches off when a serious collision occurs.

The crash test is just a phase to achieving a zero traffic fatalities target by 2050 and halving the number of traffic facilities and serious injuries by 2030 compared to 2020. Mercedes-Benz targets a zero accidents goal involving a car produced by them by 2050.

The crash test used four female and male dummies. The safety experts place a female dummy in the driver's seat in both cars. Dubbed the Hybrid III 5th Percentile Female, the dummy is currently used in the automotive industry for frontal collision tests.

In medical terms, the "percentile" refers to a measure of the dispersion of a statistical distribution sorted by rank or size of individual values. For instance, if the size of a 12-month-old child is the 10th percentile, it means that 90% of the children of the same age and gender are larger and 10% are smaller.

The dummy corresponds to a woman of approximately 1.5 meters (4’92”) tall and weighing around 49 kilograms (108 pounds). Statistics show that only 5 percent of the women worldwide are smaller or lighter than that. In order to design the protection systems for the widest possible range of customers, Mercedes-Benz has been using fifth percentile female dummies in crash tests for years. Dr. Hanna Paul, Head of Dummy Technology for Mercedes-Benz AG, explains that dummies are not human dolls, but measuring instruments corresponding to the human anatomy.

The other fifth percentile female was a passenger in the EQA, while in the passenger seat of the EQS SUV was a Hybrid III 50th Percentile dummy, which is the equivalent of a 78-kilogram (172 pounds) male of average height.

Mercedes-Benz is rolling out a new campaign called "Safety Symphony." The film included in the campaign will showcase what happens in the split second of the crash in super slow motion. The technique proves how important it is that, in this fraction of a second, all safety systems work and coordinate properly to protect the lives of those on board.

The safety experts claim that this coordination of all safety systems is like a symphony in which all instruments coordinate for the perfect harmony. The film will be uploaded on all Mecrcedes-Benz social media channels later this year with the hashtag #allforsafety.

The world's first public two-car electric crash test took place at the Technology Center for Vehicle Safety in Sindelfingen, where the company has been conducting such procedures since 2016. The center integrates three highly flexible crash lanes and a support-free area of over 8,000 square meters.

In Sindelfingen, Mercedes-Benz conducts up to 900 crash tests and 1,700 sled tests per year.

But Mercedes-Benz went further and used two real cars, the EQA crossover and the EQS SUV, weighing 2.2 and 3 tons, respectively. And instead of the required speed, the two of them traveled toward each other at 56 kph (35 mph). This translates into higher overall crash energy compared to what the regulations demand.

The real-life crash confirmed what the numerous computer simulations had previously shown. After the crash, both cars look terrible. The deformation might seem alarming for those who are not experts. However, the Mercedes-Benz engineers noticed that both cars effectively absorbed the energy of the collision by deforming like that and reduced the forces applied on the occupants.

And, the most important part of all, the passenger safety cell of both electric cars remained intact, and doors could still be opened. In an emergency situation, the opening of doors by the first responders and the rescue personnel might be a matter of life and death.

The crumple zones acted correctly in the frontal collision and did the job they were designed for. They were practically destroyed, but kept everything else safe.

The engineers also noted the high-voltage system of the EQA and the EQS SUV switched off automatically on the impact, while batteries and high-voltage components did not sustain any damage at all. That is because the carmaker developed a multi-stage protection concept for its electric cars, with separate positive and negative wiring, as well as self-monitoring high-voltage system, which automatically switches off when a serious collision occurs.

The crash test is just a phase to achieving a zero traffic fatalities target by 2050 and halving the number of traffic facilities and serious injuries by 2030 compared to 2020. Mercedes-Benz targets a zero accidents goal involving a car produced by them by 2050.

The crash test used four female and male dummies. The safety experts place a female dummy in the driver's seat in both cars. Dubbed the Hybrid III 5th Percentile Female, the dummy is currently used in the automotive industry for frontal collision tests.

The dummy corresponds to a woman of approximately 1.5 meters (4’92”) tall and weighing around 49 kilograms (108 pounds). Statistics show that only 5 percent of the women worldwide are smaller or lighter than that. In order to design the protection systems for the widest possible range of customers, Mercedes-Benz has been using fifth percentile female dummies in crash tests for years. Dr. Hanna Paul, Head of Dummy Technology for Mercedes-Benz AG, explains that dummies are not human dolls, but measuring instruments corresponding to the human anatomy.

The other fifth percentile female was a passenger in the EQA, while in the passenger seat of the EQS SUV was a Hybrid III 50th Percentile dummy, which is the equivalent of a 78-kilogram (172 pounds) male of average height.

Mercedes-Benz is rolling out a new campaign called "Safety Symphony." The film included in the campaign will showcase what happens in the split second of the crash in super slow motion. The technique proves how important it is that, in this fraction of a second, all safety systems work and coordinate properly to protect the lives of those on board.

The world's first public two-car electric crash test took place at the Technology Center for Vehicle Safety in Sindelfingen, where the company has been conducting such procedures since 2016. The center integrates three highly flexible crash lanes and a support-free area of over 8,000 square meters.

In Sindelfingen, Mercedes-Benz conducts up to 900 crash tests and 1,700 sled tests per year.