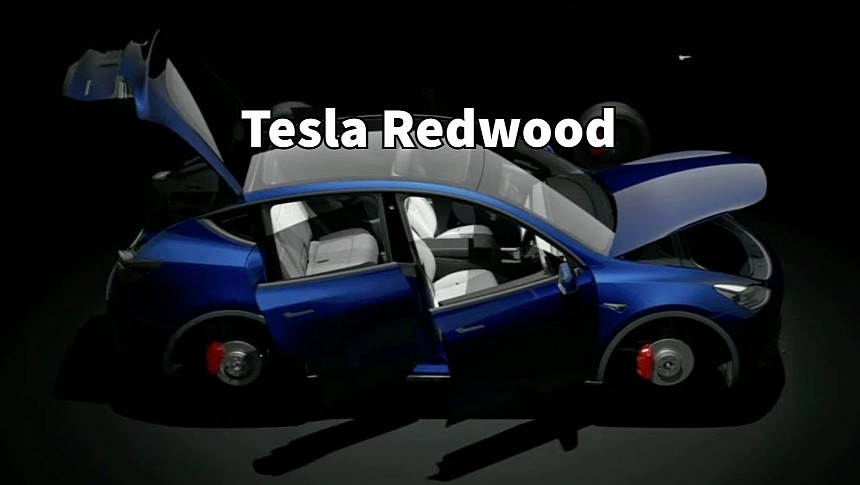

Tesla has reportedly notified suppliers that it wants to start production of a new mass-market EV codenamed "Redwood" in mid-2025. This looks like the $25,000 next-generation EV that Tesla was planning alongside the company's robotaxi. Both vehicles will use a new automotive platform that Tesla is developing at Giga Texas.

Rumors about a more affordable Tesla EV have been around for many years. To be fair, this was part of the original Master Plan and reiterated in the Master Plan Part Deux. However, in light of skyrocketing vehicle prices in 2021-2022, Elon Musk was less inclined to consider a cheaper Tesla. After all, the EV maker could barely produce enough cars to satisfy demand even at those outrageous prices, so why bother with a cheaper product?

But soon, the market would violently switch from a high-demand environment to the exact opposite in the second half of 2022. Tesla needed a miracle to keep its planned growth in the double-digit territory. At that time, people around Elon Musk convinced him to put the $25,000 EV back on the menu. It took some effort, as Walter Isaacson revealed in his book about Elon Musk, but they were able to sell the idea to Musk as the only way Tesla could bring the robotaxi to market.

The start of 2023 was something that Tesla fans and the automotive industry at large will never forget. Tesla talked about its next-generation EV platform and vehicles and almost simultaneously cut the prices of its entire lineup by almost 25% in some cases. These moves were a direct response to the EV demand waning. That's why the next-generation EVs were considered paramount for Tesla's plans to scale to 20 million EVs by 2030.

Tesla "Redwood" compact EV will start production in June 2025

The $25,000 EV model was fast-tracked after Tesla announced a new gigafactory in Mexico, with a radically new manufacturing process tailored for the new compact EV. After a couple of years of stagnation, Tesla was becoming exciting again, and some even hoped the new model might start production by the end of 2024. Well, not so fast because it soon became apparent that Giga Mexico would not become operational as fast as Tesla planned.

To mitigate this situation, Tesla switched course again and decided to develop the next-generation EV platform and the new unboxed vehicle manufacturing process at Giga Texas instead. By the time everything is ready, Giga Mexico will also be able to produce the new model, speeding up development. Hopefully, this is precisely what happened because a new report claims that Tesla is now targeting next summer to start production of its compact EV.

According to a Reuters report, Tesla has already notified its suppliers to plan for a production start of a new mass-market EV codenamed "Redwood" in June 2025. To predict production costs, Tesla sent "requests for quotes" for the Redwood model to suppliers last year. Reuters sources claim that Tesla forecasted a weekly production volume of 10,000 vehicles.

The Redwood codename is interesting, considering the connection Tesla has with JB Straubel, the founder of Redwood Materials. This specialized in recycling Li-ion batteries, but it recently announced plans to open a mammoth cathode plant in the US with enough capacity to supply 1 million EVs per year. Given the extreme scale, this is undoubtedly connected with Tesla's Redwood EVs, which will be produced in enough volumes to keep the Redwood Materials cathode plant busy.

But soon, the market would violently switch from a high-demand environment to the exact opposite in the second half of 2022. Tesla needed a miracle to keep its planned growth in the double-digit territory. At that time, people around Elon Musk convinced him to put the $25,000 EV back on the menu. It took some effort, as Walter Isaacson revealed in his book about Elon Musk, but they were able to sell the idea to Musk as the only way Tesla could bring the robotaxi to market.

The start of 2023 was something that Tesla fans and the automotive industry at large will never forget. Tesla talked about its next-generation EV platform and vehicles and almost simultaneously cut the prices of its entire lineup by almost 25% in some cases. These moves were a direct response to the EV demand waning. That's why the next-generation EVs were considered paramount for Tesla's plans to scale to 20 million EVs by 2030.

Tesla "Redwood" compact EV will start production in June 2025

The $25,000 EV model was fast-tracked after Tesla announced a new gigafactory in Mexico, with a radically new manufacturing process tailored for the new compact EV. After a couple of years of stagnation, Tesla was becoming exciting again, and some even hoped the new model might start production by the end of 2024. Well, not so fast because it soon became apparent that Giga Mexico would not become operational as fast as Tesla planned.

To mitigate this situation, Tesla switched course again and decided to develop the next-generation EV platform and the new unboxed vehicle manufacturing process at Giga Texas instead. By the time everything is ready, Giga Mexico will also be able to produce the new model, speeding up development. Hopefully, this is precisely what happened because a new report claims that Tesla is now targeting next summer to start production of its compact EV.

According to a Reuters report, Tesla has already notified its suppliers to plan for a production start of a new mass-market EV codenamed "Redwood" in June 2025. To predict production costs, Tesla sent "requests for quotes" for the Redwood model to suppliers last year. Reuters sources claim that Tesla forecasted a weekly production volume of 10,000 vehicles.

Is there any connection with JB Straubel's Redwood Materials?

Musk said in May 2023 that Tesla is developing two mass-market EVs, with a potential for combined sales of 5 million units per year. One will be a compact crossover, which some people described as a shrunk Model Y. The other will be the Tesla robotaxi, although this would not make much sense unless Tesla solves vehicle autonomy. Both EVs will use Tesla's next-generation architecture, codenamed NV9X. This is optimized for the unboxed vehicle manufacturing process, which allows Tesla to cut production costs in half compared with current Model 3/Y EVs.The Redwood codename is interesting, considering the connection Tesla has with JB Straubel, the founder of Redwood Materials. This specialized in recycling Li-ion batteries, but it recently announced plans to open a mammoth cathode plant in the US with enough capacity to supply 1 million EVs per year. Given the extreme scale, this is undoubtedly connected with Tesla's Redwood EVs, which will be produced in enough volumes to keep the Redwood Materials cathode plant busy.