It took a while to clarify why Amprius had different performance numbers for what appeared to be the same cell, but it was worth the wait. The company's chief technical officer (CTO) answered all the questions we had and presented a more precise scenario of what Amprius is doing. For starters, Ionel Stefan explained that the apparently lowering energy density actually refers to different products with specific applications. Although that solves the mystery, these purposes are what really matters to everyone curious about Amprius' work.

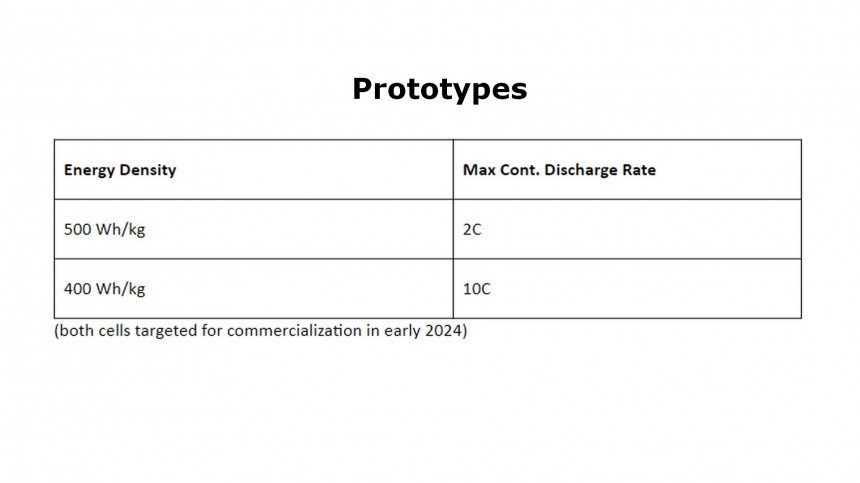

If you are not familiar with the battery manufacturer, it announced in March a 500-Wh/kg cell it was working on. More recently, it disclosed its "newest ultra-high-power-high-energy lithium-ion battery," but it offered 400 Wh/kg. It seemed the company was talking about a single cell, but the one with 500 Wh/kg is a high-energy cell, while the other focuses on power. Stefan elaborated on that.

"The biggest difference between the 500-Wh/kg cell and the 400-Wh/kg cell is the difference in the thickness (loading) of the electrodes. High-energy designs have high-loading and thick electrodes, which limit power capability (the electrolyte and ions have to diffuse in a thick layer of coated electrode, and electrons have to travel over the entire thickness of the electrode to the current collector metal foil)."

The recipe focused on power needs other ingredients.

"High-power designs have thin and low-loading electrodes for fast transport of ions and electrons. However, thin electrodes have a higher mass ratio of metal foils (inactive material) relative to cathode and anode materials (active materials), which reduces energy density. (...) Only active materials (the materials that store lithium, i.e., cathode powders such as LCO, NMC, and anode materials such as graphite and silicon) contribute/increase energy density, while inactive materials (foils, electrolyte, separator, pouch) decrease energy density. Thus, the higher the ratio of active to inactive materials, the higher the energy density."

That said, the 500-Wh/kg cell and the 400-Wh/kg battery are very diverse solutions for specific applications.

"The ultra-high energy density cell of 500 Wh/kg has the highest energy per kg among lithium-ion cells in the industry, but its energy can be discharged only slowly, over 5-10 hours (C/5 to C/10 rate of discharge). (The) target application is high-altitude platform systems (HAPS) and other applications where the operation time on one charge is long. The ultra-high power cell of 400 Wh/kg, while having less energy per kg than the high-energy design, can be discharged very fast, in minutes (10C is equivalent to a complete discharge in 6 minutes), delivering all its energy over this time period, supporting high power applications, such as electric flight and powerful cars."

Both of these cells are still prototypes that should reach production in 2024, but Amprius is already selling some of its solutions with its silicon anode platform.

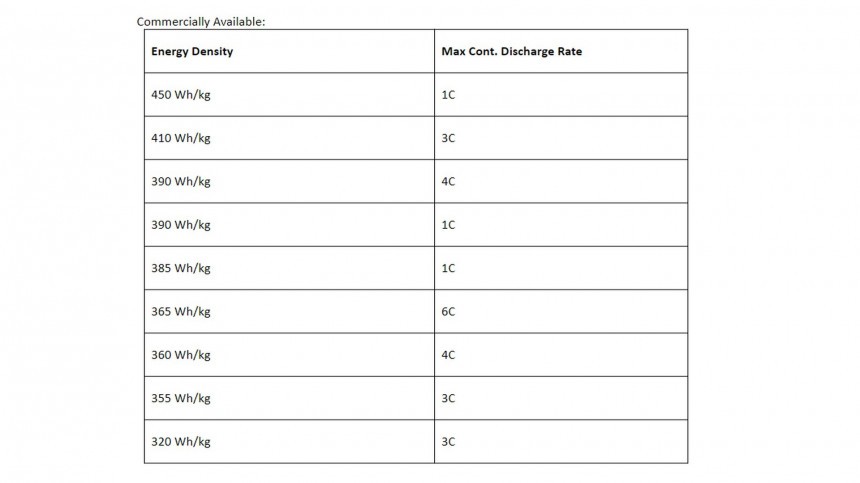

"Amprius' products are offered with different chemistries that include the following: (Si/LCO, Si/NMC, Si/NMCA), each one with at least three power levels (high power, high energy, and balanced). Any of these chemistries can be built in different form factors from a list of formats already in manufacturing. There are currently a set of five variations available, and clients can customer-order their own variations."

The cell with the highest energy density from the company that is already for sale offers 450 Wh/kg. It is a high-energy battery with a relatively low discharge rate: only 1C, which corresponds to a complete discharge in one hour. The high-power cell from Amprius delivers 365 Wh/kg at a much higher rate: 6C, which means a full discharge in 10 minutes. There is also a 390-Wh/kg option, but its discharge rate is only 4C (25 minutes). You can see all options currently available in the table in our image gallery.

When Amprius said the 500-Wh/kg cell could have a lifespan between 200 and 1,200 cycles, that seemed too low for battery electric vehicles. Stefan already clarified this cell does not focus on BEVs, but that does not mean the company does not have them as a target.

"Amprius is working with the United States Advanced Battery Consortium (USABC, which includes GM, Ford, and Stellantis) and other OEMs to apply its technologies to EVs. As a note, the USABC and Department of Energy goal for EV batteries' cycle life is 1,000 cycles, so 1,200 cycles is sufficient. The reason is that for a typical range of 250 miles, 1,000 cycles represent 250,000 miles, a reasonable life for a battery set, well above the standard warranty."

The issue is that BEVs should last a lot more than that. As they do not emit carbon dioxide or pollutant gases, there is no reason for them to be removed from the streets: the longer they can perform their duties, the better. Only planned obsolescence explains killing BEVs after 250,000 miles. I asked Stefan if it is possible to have high-energy or high-power batteries with a longer lifespan.

"Cell design decisions are made on a case-by-case basis in the power/energy/cycle life/cost space based on customer and application requirements. Although the above metrics are connected to each other, the relationship is not necessarily linear (cannot always trade one for the other)."

"The biggest difference between the 500-Wh/kg cell and the 400-Wh/kg cell is the difference in the thickness (loading) of the electrodes. High-energy designs have high-loading and thick electrodes, which limit power capability (the electrolyte and ions have to diffuse in a thick layer of coated electrode, and electrons have to travel over the entire thickness of the electrode to the current collector metal foil)."

"High-power designs have thin and low-loading electrodes for fast transport of ions and electrons. However, thin electrodes have a higher mass ratio of metal foils (inactive material) relative to cathode and anode materials (active materials), which reduces energy density. (...) Only active materials (the materials that store lithium, i.e., cathode powders such as LCO, NMC, and anode materials such as graphite and silicon) contribute/increase energy density, while inactive materials (foils, electrolyte, separator, pouch) decrease energy density. Thus, the higher the ratio of active to inactive materials, the higher the energy density."

That said, the 500-Wh/kg cell and the 400-Wh/kg battery are very diverse solutions for specific applications.

"The ultra-high energy density cell of 500 Wh/kg has the highest energy per kg among lithium-ion cells in the industry, but its energy can be discharged only slowly, over 5-10 hours (C/5 to C/10 rate of discharge). (The) target application is high-altitude platform systems (HAPS) and other applications where the operation time on one charge is long. The ultra-high power cell of 400 Wh/kg, while having less energy per kg than the high-energy design, can be discharged very fast, in minutes (10C is equivalent to a complete discharge in 6 minutes), delivering all its energy over this time period, supporting high power applications, such as electric flight and powerful cars."

"Amprius' products are offered with different chemistries that include the following: (Si/LCO, Si/NMC, Si/NMCA), each one with at least three power levels (high power, high energy, and balanced). Any of these chemistries can be built in different form factors from a list of formats already in manufacturing. There are currently a set of five variations available, and clients can customer-order their own variations."

The cell with the highest energy density from the company that is already for sale offers 450 Wh/kg. It is a high-energy battery with a relatively low discharge rate: only 1C, which corresponds to a complete discharge in one hour. The high-power cell from Amprius delivers 365 Wh/kg at a much higher rate: 6C, which means a full discharge in 10 minutes. There is also a 390-Wh/kg option, but its discharge rate is only 4C (25 minutes). You can see all options currently available in the table in our image gallery.

"Amprius is working with the United States Advanced Battery Consortium (USABC, which includes GM, Ford, and Stellantis) and other OEMs to apply its technologies to EVs. As a note, the USABC and Department of Energy goal for EV batteries' cycle life is 1,000 cycles, so 1,200 cycles is sufficient. The reason is that for a typical range of 250 miles, 1,000 cycles represent 250,000 miles, a reasonable life for a battery set, well above the standard warranty."

The issue is that BEVs should last a lot more than that. As they do not emit carbon dioxide or pollutant gases, there is no reason for them to be removed from the streets: the longer they can perform their duties, the better. Only planned obsolescence explains killing BEVs after 250,000 miles. I asked Stefan if it is possible to have high-energy or high-power batteries with a longer lifespan.

"Cell design decisions are made on a case-by-case basis in the power/energy/cycle life/cost space based on customer and application requirements. Although the above metrics are connected to each other, the relationship is not necessarily linear (cannot always trade one for the other)."