Every time a new sporty car is released, whether is powered by a conventional internal combustion engine or all-electric-driven, manufacturers like to boast about how well they perform through corners. They state that they have programed differentials to perform miracles and the way they do it is using torque vectoring.

A differential transfers engine torque to the wheels and this technology provides it with the ability to vary that torque to each driven wheel.

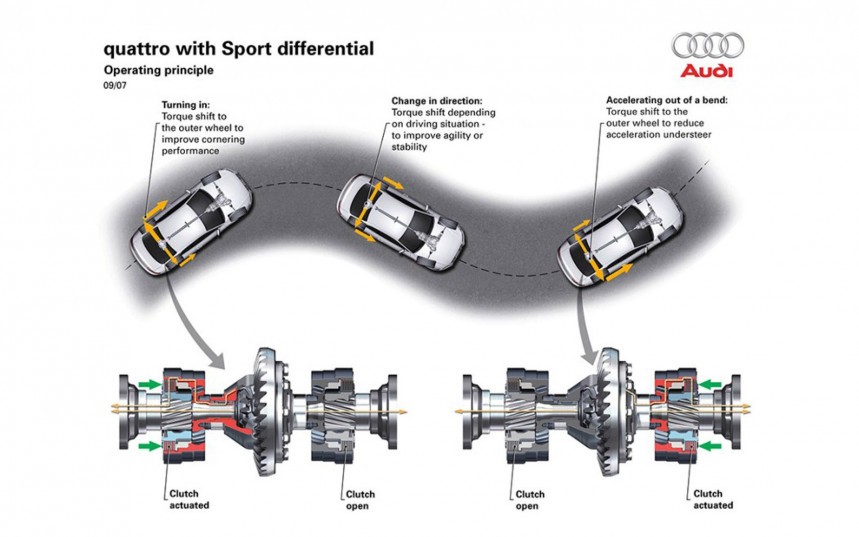

Since differentials generally include only mechanical components, to enable torque vectoring an electronic monitoring system is required to control the clutch pack on either side of the differential.

Front or rear-wheel drive differentials are less complex than their all-wheel-drive counterparts because they only vary torque between two wheels.

An FWD differential must monitor rotational and steering angles of the wheels, and as these vary during driving, different forces are applied to them. The torque vectoring system analyzes these forces and adjusts torque, accordingly, increasing or decreasing the amount delivered to a certain wheel.

An RWD differential with this technology works in a simpler manner, without having to track steering angles if the vehicle in question does not feature rear-wheel steering.

This drastically improves a vehicle’s capability to maintain traction in poor conditions or when entering a corner at high speeds. When one wheel begins to slip, the differential decreases the torque to that wheel, effectively braking it, while increasing power to the opposite wheel, helping the vehicle maintain stability.

However, most torque-vectoring differentials are found on AWD vehicles. One such basic differential oscillates torque between the front and rear wheels. This means that under normal driving conditions the front wheels get a predetermined percentage of the engine torque while the rear wheels receive the rest. When the situation demands it, this percentage can vary to increase stability and performance.

Mitsubishi was among the first manufacturers to use an early version of this technology with its Active Yaw Control on the Lancer Evolution IV rear axle.

It managed which rear wheel got more power with an electronically controlled wet clutch pack on either side of the differential gears in the rear axle, minimizing understeer and helping the rally Evo car driven by Tommi Makinen dominate the World Rally Championship in the late ‘90s.

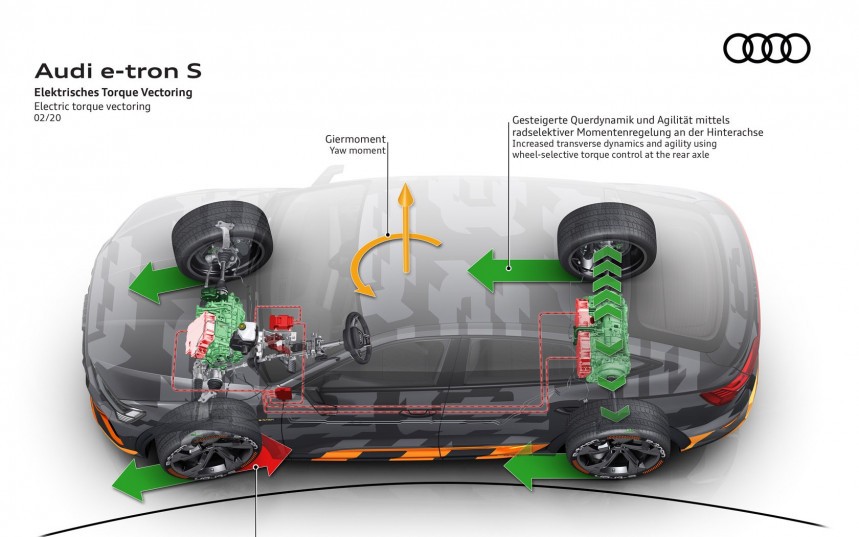

These days, advanced AWD differentials have the ability to adjust torque between each individual wheel, making the vehicles even more stable and maneuverable. These advanced differentials use the torque vectoring system to monitor each wheel independently and distribute available torque to match driving conditions.

In EVs and hybrids, this can be implemented when two motors are used to drive the wheels. Things are much simpler since torque can be managed by controlling the power distribution between them. The electric motors give the system much more versatility over how it directs torque, so this technology is more effective on these vehicles.

There is also another form called torque vectoring by braking. It works roughly the same but rather than include a clutch pack on either side of the differential, the system is operated by the braking system.

Torque vectoring has fundamentally changed the way modern vehicles handle and allow a modern car to be a lot faster around a track, for example, than a much more powerful supercar from the ‘80s. But, more importantly, it makes modern cars a lot safer in poor road conditions.

Since differentials generally include only mechanical components, to enable torque vectoring an electronic monitoring system is required to control the clutch pack on either side of the differential.

Front or rear-wheel drive differentials are less complex than their all-wheel-drive counterparts because they only vary torque between two wheels.

An FWD differential must monitor rotational and steering angles of the wheels, and as these vary during driving, different forces are applied to them. The torque vectoring system analyzes these forces and adjusts torque, accordingly, increasing or decreasing the amount delivered to a certain wheel.

An RWD differential with this technology works in a simpler manner, without having to track steering angles if the vehicle in question does not feature rear-wheel steering.

This drastically improves a vehicle’s capability to maintain traction in poor conditions or when entering a corner at high speeds. When one wheel begins to slip, the differential decreases the torque to that wheel, effectively braking it, while increasing power to the opposite wheel, helping the vehicle maintain stability.

Mitsubishi was among the first manufacturers to use an early version of this technology with its Active Yaw Control on the Lancer Evolution IV rear axle.

It managed which rear wheel got more power with an electronically controlled wet clutch pack on either side of the differential gears in the rear axle, minimizing understeer and helping the rally Evo car driven by Tommi Makinen dominate the World Rally Championship in the late ‘90s.

These days, advanced AWD differentials have the ability to adjust torque between each individual wheel, making the vehicles even more stable and maneuverable. These advanced differentials use the torque vectoring system to monitor each wheel independently and distribute available torque to match driving conditions.

There is also another form called torque vectoring by braking. It works roughly the same but rather than include a clutch pack on either side of the differential, the system is operated by the braking system.

Torque vectoring has fundamentally changed the way modern vehicles handle and allow a modern car to be a lot faster around a track, for example, than a much more powerful supercar from the ‘80s. But, more importantly, it makes modern cars a lot safer in poor road conditions.