The design of present-day aircraft and everything related to them has largely remained the same for decades. A central metal cylinder with wings to either side, on which the aircraft's engines are fitted. Those engines, in turn, are almost always enclosed in a nacelle, protecting them from harm. But what if future aircraft would boast some of the engine components on the outside?

That's the premise behind a piece of technology called Open Fan. As the name says, it's a design that leaves the powerplant's fan unshielded, making it look more like the propellers of old.

But why would anyone go back to what may seem like an older way of doing things? The answer is simple: an open fan architecture is one way to reduce an aircraft's fuel consumption and CO2 emissions, and everyone is chasing that at the moment.

In their quest to make engines more efficient, aircraft engine makers have gradually increased the size of the fan diameters. So much so, that it'll probably become tricky in the near future to fit them inside nacelles.

Thus the natural evolution of the fan has only one path to take, which is an open architecture. As it happens, such a design is also "the most efficient and sustainable option to improve the propulsive efficiency of the engine."

That's the opinion of the group of companies behind what is known as the RISE program. It's an effort led by engine maker CFM International, an evenly split joint venture between Safran and GE Aerospace. The program aims, no more and no less, to design new means of propulsion that are capable of releasing 20 percent fewer CO2 emissions compared to "today's most efficient engines."

The Open Fan powerplant, as it is known, would do so not only thanks to its design but also based on the fact it will be fully compatible with Sustainable Aviation Fuel (SAF) and even hydrogen. When using that emissions are expected to drop by as much as 80 percent.

The eco-friendly approach does not mean an aircraft powered by open fan engines would be less potent. The goal is to make the tech in such a way as to allow the planes to reach speeds of Mach 0.8, the usual speed current single-aisle aircraft are capable of reaching.

The exact specs of such an engine are not entirely known, but we have info that it will be made using carbon fiber composite blades, metal alloy and ceramic components, and an "advanced compact core."

The project is still in its early stages, but one of the companies involved, Safran, announced this week what may very well be the first major milestone of the program.

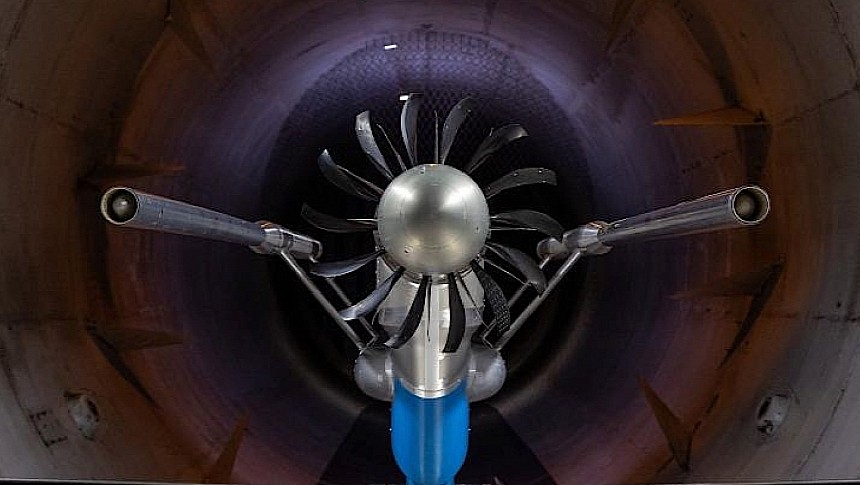

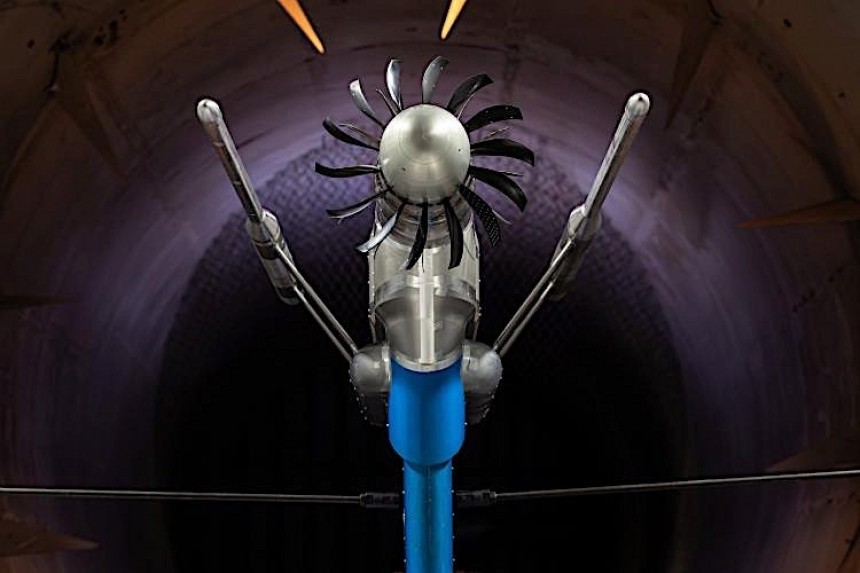

The company announced it has begun the first wind tunnel tests for something called the ECOENGInE. That would be a 1: scale demonstrator of an open fan engine that would validate the tech and materials.

The tests are being performed in the world's largest sonic wind tunnel. It's called the S1MA tunnel, it is located in in Modane, France, and it is operated by French aerospace research agency ONERA.

The tunnel is 8 meters across (26 feet) and is powered by two contra-rotating fans driven by Pelton turbines, capable of delivering 88 MW of power. The fans need just three minutes to bring the air in the tunnel from zero to Mach 1, the speed of sound.

Its size allows for the testing of both standalone engines and units mounted on wing structures. Moreover, it can also accommodate the testing of helicopter rotors, but also full-scale missiles, which can be tested even with their engines running.

The test cycle that began in France this week will cover at first the aerodynamic and acoustic performance of the fan module now being researched. The design of the fan blades, which play a crucial role in the efficiency levels of this kind of engine, is also under the scrutiny of aerospace engineers.

Safran and its partners in this program will put the ECOENGInE through its paces for some 200 hours in the first run. Once this stage is complete, the unit will be mounted on a wing section and tested some more.

The French aerospace company says the multi-stage test plan for the demonstrator and its successors will run from this year until 2028. The companies involved believe the open fan engines should become commercially available by the end of the current decade. By the middle of the next one, we should be seeing them deployed on single-aisle commercial jets.

Those worrying an open fan jet engine may be a lot noisier than the existing ones are reassured the engine's noise signature "will meet anticipated future regulations."

We expect more details on the new technology to surface as the testing program advances, and we'll update as soon as we learn more.

But why would anyone go back to what may seem like an older way of doing things? The answer is simple: an open fan architecture is one way to reduce an aircraft's fuel consumption and CO2 emissions, and everyone is chasing that at the moment.

In their quest to make engines more efficient, aircraft engine makers have gradually increased the size of the fan diameters. So much so, that it'll probably become tricky in the near future to fit them inside nacelles.

Thus the natural evolution of the fan has only one path to take, which is an open architecture. As it happens, such a design is also "the most efficient and sustainable option to improve the propulsive efficiency of the engine."

That's the opinion of the group of companies behind what is known as the RISE program. It's an effort led by engine maker CFM International, an evenly split joint venture between Safran and GE Aerospace. The program aims, no more and no less, to design new means of propulsion that are capable of releasing 20 percent fewer CO2 emissions compared to "today's most efficient engines."

The Open Fan powerplant, as it is known, would do so not only thanks to its design but also based on the fact it will be fully compatible with Sustainable Aviation Fuel (SAF) and even hydrogen. When using that emissions are expected to drop by as much as 80 percent.

The exact specs of such an engine are not entirely known, but we have info that it will be made using carbon fiber composite blades, metal alloy and ceramic components, and an "advanced compact core."

The project is still in its early stages, but one of the companies involved, Safran, announced this week what may very well be the first major milestone of the program.

The company announced it has begun the first wind tunnel tests for something called the ECOENGInE. That would be a 1: scale demonstrator of an open fan engine that would validate the tech and materials.

The tests are being performed in the world's largest sonic wind tunnel. It's called the S1MA tunnel, it is located in in Modane, France, and it is operated by French aerospace research agency ONERA.

The tunnel is 8 meters across (26 feet) and is powered by two contra-rotating fans driven by Pelton turbines, capable of delivering 88 MW of power. The fans need just three minutes to bring the air in the tunnel from zero to Mach 1, the speed of sound.

The test cycle that began in France this week will cover at first the aerodynamic and acoustic performance of the fan module now being researched. The design of the fan blades, which play a crucial role in the efficiency levels of this kind of engine, is also under the scrutiny of aerospace engineers.

Safran and its partners in this program will put the ECOENGInE through its paces for some 200 hours in the first run. Once this stage is complete, the unit will be mounted on a wing section and tested some more.

The French aerospace company says the multi-stage test plan for the demonstrator and its successors will run from this year until 2028. The companies involved believe the open fan engines should become commercially available by the end of the current decade. By the middle of the next one, we should be seeing them deployed on single-aisle commercial jets.

Those worrying an open fan jet engine may be a lot noisier than the existing ones are reassured the engine's noise signature "will meet anticipated future regulations."

We expect more details on the new technology to surface as the testing program advances, and we'll update as soon as we learn more.