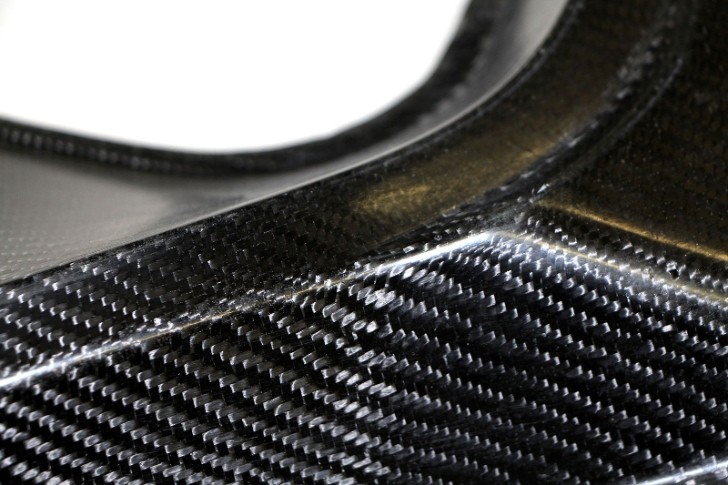

Sure, we all know aluminum and even some of the classic metals are sort of overrated when it comes to the automative industry nowadays. The population of the world is getting bigger by the second, pollution is getting worse and resources are not so cheap to get. Since carbon fiber is the new cool, German scientists are currently working on various hybrid materials made of hemp, cotton or wood combined with the so popular material to make it affordable.

Even though they have experienced quite an impressive popularity in the past years, we all now that carbon fiber-reinforced plastics are still not easy to produce, nor are they cheap enough yet. They use it in Formula 1 racing, in the aviation industry and, of course, in the production of extremely expensive cars most commonly known as hypercars.

The high price and its processing are currently a major drawback, which is why they have still haven't found their path into wide-scale production so far. Glass fibers, on the other hand, are affordable but quite heavy in comparison. And here’s where researchers at the Application Center for Wood Fiber Research HOFZET of the Fraunhofer Institute for Wood Research, the Wilhem-Klauditz-Institut WKI in Braunschweig, Lower Saxony, Germany come in.

In just a couple of words, the scientists claim there could be a way for natural fibers of botanical origin to take the place of glass and other plastics. Variants derived from hemp, flax, cotton and wood are about as affordable as glass fiber, but have a lower density. What’s even better, these materials could later produce energy without polluting, which means incinerating them will not leave any residues.

”Depending on the application, we are therefore combining carbon with various bio-based textile fibers,” explains Prof. Dr.-Ing. Hans-Josef Endres, head of the Application Center for Wood Fiber Research. So far, they are only using these materials in parts where the mechanical stress is not that big. This way, scientists can leverage the strengths of the respective fibers and get rid of the disadvantages to a great extent.

Researchers will present their work at the nature.tec professional trade show at the Grune Woche from January 16 to 25 in Berlin. Here, they will also present fiber form-pressed components for the automotive industry.

The high price and its processing are currently a major drawback, which is why they have still haven't found their path into wide-scale production so far. Glass fibers, on the other hand, are affordable but quite heavy in comparison. And here’s where researchers at the Application Center for Wood Fiber Research HOFZET of the Fraunhofer Institute for Wood Research, the Wilhem-Klauditz-Institut WKI in Braunschweig, Lower Saxony, Germany come in.

In just a couple of words, the scientists claim there could be a way for natural fibers of botanical origin to take the place of glass and other plastics. Variants derived from hemp, flax, cotton and wood are about as affordable as glass fiber, but have a lower density. What’s even better, these materials could later produce energy without polluting, which means incinerating them will not leave any residues.

”Depending on the application, we are therefore combining carbon with various bio-based textile fibers,” explains Prof. Dr.-Ing. Hans-Josef Endres, head of the Application Center for Wood Fiber Research. So far, they are only using these materials in parts where the mechanical stress is not that big. This way, scientists can leverage the strengths of the respective fibers and get rid of the disadvantages to a great extent.

It could increase the durability of the materials by up to 50%

“The outcome: the parts are cost-effective, have a very high degree of durability, posses excellent acoustic properties and are substantially more ecological than pure carbon components”. To one extent, these new hybrid fibers could even increase the durability of the materials by up to 50 percent.Researchers will present their work at the nature.tec professional trade show at the Grune Woche from January 16 to 25 in Berlin. Here, they will also present fiber form-pressed components for the automotive industry.