When I wrote about Mazda’s attempt to create the perfect range extender, I mentioned I wanted to examine the ideas that seem to be closer to that goal. Unfortunately, the Japanese company’s attempt with the MX-30 R-EV failed, giving us a rotary internal combustion engine (ICE) that weighs as much as Ford’s 1-liter Ecoboost unit. There is no better way to start presenting the other range extender options than one that turned the Wankel inside out.

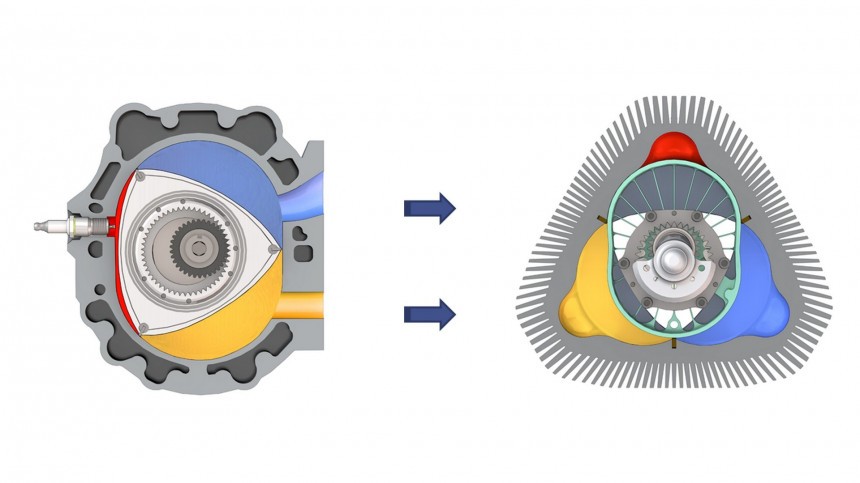

This is what LiquidPiston did to create its X-Engines. As the company describes them, they “have a peanut-shaped (trochoidal) rotor within a trilobed housing,” while conventional rotary engines “have a triangular rotor in a ‘peanut’ shaped (trochoidal) housing.” That makes the combustion chamber stationary, which “made it possible to directly lubricate the stationary apex (tip) seals.” That’s because they are inserted in the housing, not the rotor.

“Because the seals are stationary, they don’t bounce around like the Wankel seals, which are on the rotor. The more precise lubrication and reduced tip seal wear also help make the X-Engine more durable.”

Curiously, LiquidPiston buys its seals directly from Mazda, but installing them in the housing brings another advantage: easier maintenance. The seal cartridges can be replaced “like changing the spark plugs” of a conventional vehicle. In other words, it is not necessary to tear the engine apart to do that. LiquidPiston estimates they have to be replaced after “100,000 miles or so.”

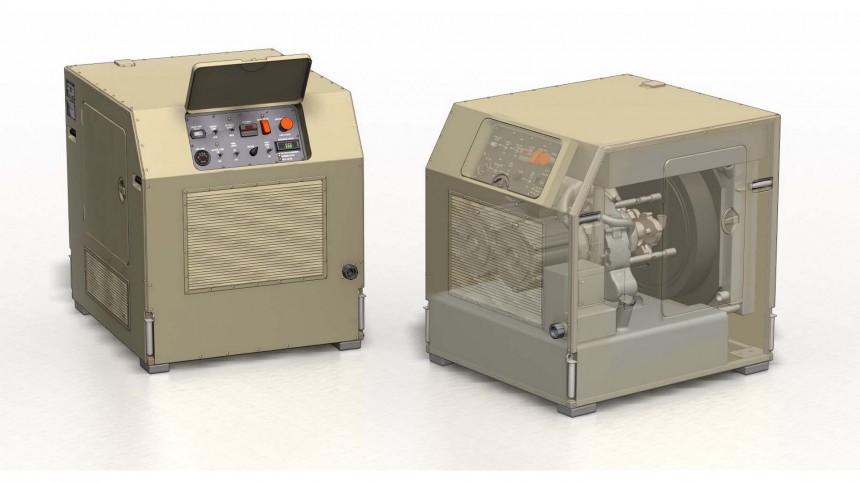

According to the company, “the latest generation of Mazda’s rotary engine goes about 150,000 to 200,000 miles or approximately 3,000 hours,” which would be “an indication of how long our XTS-210 may last.” With the improvements, this X-Engine should have a larger lifespan, but the company is still “in the initial stages of durability testing the XTS-210.” This design is still in the prototype phase. LiquidPiston wants to deliver an advanced probe unit to the Army by Q4 2024, where it will be used as a compact electricity generator.

The company states that its X-Engines have been “successfully tested with jet fuels, kerosene, gasoline, propane, hydrogen, and even vodka.” Apart from the ICE, LiquidPiston also developed the High Efficiency Hybrid Cycle (HEHC), which has some similarities to the Atkinson cycle in the sense that both use a larger expansion volume than the compression volume. That means the engine spends less energy compressing the air-fuel mix and seizes more energy from the expansion of the gases generated by the combustion, as the Atkinson cycle does in most hybrid vehicles.

With diesel, HEHC uses a high compression ratio so that the mix is compression-ignited (CI-HEHC). The company also works with spark plugs to burn gasoline, “biofuels, and Sustainable Aviation Fuel (SAF),” but it prefers diesel, “a stable fuel, which makes it ideal for military use because it doesn’t ignite as easily as ‘light’ fuels like gasoline do, making it safer to transport and store. That is critically important to the military for safety and logistics (single fuel supply line) reasons.”

There are other important aspects involved. The lower compression ratio “means lower efficiency.” On the other hand, compression ignition ensures “an optimized thermodynamic cycle to convert more of the energy contained in the fuel into shaft work output.” LiquidPiston said its engines “are up to 30% more fuel efficient than comparably rated engines.” Not only that: these X-Engines are also much smaller than current ones because they are two-stroke engines with none of the disadvantages these machines present when they use pistons.

LiquidPiston said they do not burn oil, which does not have to be mixed with the fuel: it is applied directly on the seals. Each full rotor turn produces a power stroke, which saves work but also leaves fuel unburned in reciprocating engines. HEHC avoids that with a “more complete fuel combustion” that “generates less particulate and CO2 emissions.”

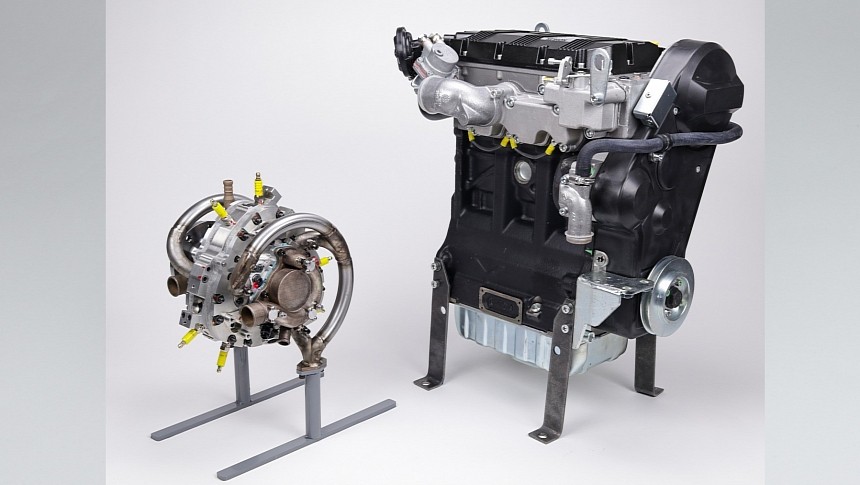

The XTS-210 is the size of a basketball. The main image in this article shows it side by side with a diesel engine that offers the same output. The difference between them is staggering. The XTS-210 is also air-cooled. Injecting water in its three combustion chambers can also cool the engine and improve its efficiency at the same time: the steam that forms increases the chamber pressure. LiquidPiston stressed that its engines “can use post-treatment technologies available to all combustion engines in order to be fully compliant with emissions regulations.”

When I asked the company about the thermal efficiency of the X-Engines, it said the two-stroke cycle makes it difficult to compare it to mills used to power cars. The world’s most efficient one is the Geely DHE1.5 – aka Leishen Hi-X – which converts 43.32% of gasoline’s chemical energy into movement. If an X-Engine also had 500 cubic centimeters (0.5 cubic inches) per chamber, four strokes, and was turbocharged, LiquidPiston’s “target efficiency would be about 50%.” Each combustion chamber in the XTS-210 has 70 cm³ (4.3 in³).

These characteristics make LiquidPiston confident that the X-Engines would be perfect as range extenders for vehicles with a smaller battery pack than those we find in battery electric vehicles (BEVs).

“We’re hopeful about the future of BEVs, but there are still a lot of barriers hampering BEV adoption (e.g. lack of charging infrastructure; affordability for consumers). Because it's not easy to produce, afford, or easily charge a BEV yet, hybrids will play a significant role for many decades.”

By hybrids, LiquidPiston is actually talking about those that can be recharged. In other words, about plug-in hybrids electric vehicles (PHEVs).

“Hybrids combine many of the benefits of BEVs and ICE vehicles while utilizing readily available technology and infrastructure to help reduce carbon emissions in an economically viable and practical energy transition. Many of the major auto OEMs are clearly articulating and actively investing in long-term hybrid land vehicle programs.”

LiquidPiston sees its engines as a perfect fit for extended-range electric vehicles (EREVs) or PHEVs.

“Our engines are a great complement to compact, efficient, low-noise hybrid electric power systems and offer a practical pathway to use low/no-carbon fuels, like hydrogen. The XTS-210, for instance, is 80% lighter and smaller than current comparably rated diesel piston engines but just as powerful – and is optimized for hybrid-electric applications.”

As most automakers prefer to use the engines they already have, you may be asking how they could adopt LiquidPiston’s X-Engines. So did I.

“Right now, we are focused on delivering a low volume of advanced prototype units to military customers and fulfilling current Department of Defense (DoD) contracts. We recently received an $8.3 million contract from the Army to incorporate the XTS-210 into a lightweight, compact 10-kW generator set. Our long-term strategy is to partner with established engine manufacturers and systems integrators to serve higher-volume markets in the commercial sector. These partnerships could involve technology licensing, development collaboration, or a combination of licensing and co-development.”

I also asked the company about any car companies already contacting them after the X-Engines, but I only heard back that it is “not able to disclose company-specific information due to non-disclosure agreements (NDAs) at this time.” If there’s an agreement, there’s substance. That means we may hear about EREVs or PHEVs with a LiquidPiston engine in a few years, probably when the deals with the DoD are concluded.

“Because the seals are stationary, they don’t bounce around like the Wankel seals, which are on the rotor. The more precise lubrication and reduced tip seal wear also help make the X-Engine more durable.”

Curiously, LiquidPiston buys its seals directly from Mazda, but installing them in the housing brings another advantage: easier maintenance. The seal cartridges can be replaced “like changing the spark plugs” of a conventional vehicle. In other words, it is not necessary to tear the engine apart to do that. LiquidPiston estimates they have to be replaced after “100,000 miles or so.”

The company states that its X-Engines have been “successfully tested with jet fuels, kerosene, gasoline, propane, hydrogen, and even vodka.” Apart from the ICE, LiquidPiston also developed the High Efficiency Hybrid Cycle (HEHC), which has some similarities to the Atkinson cycle in the sense that both use a larger expansion volume than the compression volume. That means the engine spends less energy compressing the air-fuel mix and seizes more energy from the expansion of the gases generated by the combustion, as the Atkinson cycle does in most hybrid vehicles.

With diesel, HEHC uses a high compression ratio so that the mix is compression-ignited (CI-HEHC). The company also works with spark plugs to burn gasoline, “biofuels, and Sustainable Aviation Fuel (SAF),” but it prefers diesel, “a stable fuel, which makes it ideal for military use because it doesn’t ignite as easily as ‘light’ fuels like gasoline do, making it safer to transport and store. That is critically important to the military for safety and logistics (single fuel supply line) reasons.”

LiquidPiston said they do not burn oil, which does not have to be mixed with the fuel: it is applied directly on the seals. Each full rotor turn produces a power stroke, which saves work but also leaves fuel unburned in reciprocating engines. HEHC avoids that with a “more complete fuel combustion” that “generates less particulate and CO2 emissions.”

The XTS-210 is the size of a basketball. The main image in this article shows it side by side with a diesel engine that offers the same output. The difference between them is staggering. The XTS-210 is also air-cooled. Injecting water in its three combustion chambers can also cool the engine and improve its efficiency at the same time: the steam that forms increases the chamber pressure. LiquidPiston stressed that its engines “can use post-treatment technologies available to all combustion engines in order to be fully compliant with emissions regulations.”

These characteristics make LiquidPiston confident that the X-Engines would be perfect as range extenders for vehicles with a smaller battery pack than those we find in battery electric vehicles (BEVs).

“We’re hopeful about the future of BEVs, but there are still a lot of barriers hampering BEV adoption (e.g. lack of charging infrastructure; affordability for consumers). Because it's not easy to produce, afford, or easily charge a BEV yet, hybrids will play a significant role for many decades.”

“Hybrids combine many of the benefits of BEVs and ICE vehicles while utilizing readily available technology and infrastructure to help reduce carbon emissions in an economically viable and practical energy transition. Many of the major auto OEMs are clearly articulating and actively investing in long-term hybrid land vehicle programs.”

LiquidPiston sees its engines as a perfect fit for extended-range electric vehicles (EREVs) or PHEVs.

“Our engines are a great complement to compact, efficient, low-noise hybrid electric power systems and offer a practical pathway to use low/no-carbon fuels, like hydrogen. The XTS-210, for instance, is 80% lighter and smaller than current comparably rated diesel piston engines but just as powerful – and is optimized for hybrid-electric applications.”

“Right now, we are focused on delivering a low volume of advanced prototype units to military customers and fulfilling current Department of Defense (DoD) contracts. We recently received an $8.3 million contract from the Army to incorporate the XTS-210 into a lightweight, compact 10-kW generator set. Our long-term strategy is to partner with established engine manufacturers and systems integrators to serve higher-volume markets in the commercial sector. These partnerships could involve technology licensing, development collaboration, or a combination of licensing and co-development.”

I also asked the company about any car companies already contacting them after the X-Engines, but I only heard back that it is “not able to disclose company-specific information due to non-disclosure agreements (NDAs) at this time.” If there’s an agreement, there’s substance. That means we may hear about EREVs or PHEVs with a LiquidPiston engine in a few years, probably when the deals with the DoD are concluded.