Most of us who are aware that a concept such as ‘internal combustion’ exists (some might call it ‘a way of life’) have, at one point or another, come across the term ‘floating axle.’ The expression is widely used in 'semi-floating' or 'full-floating' variations. Still, it actually has nothing to do with fluid dynamics and buoyancy. However, the Russian Institute of ‘I Don’t Science Much, But When I Do…’ has taken the concept of the floating axle to the next level: tensegrity 'levitation.' Believe it or not, it works – then again, name something made in Russia that doesn’t.

A full-floating axle is basically a driveshaft that is not load-bearing, unlike the semi-floating type, on which the wheel is bolted directly. This obviously applies to a platform where the rear wheels are driving wheels – so Rear-Wheel Drive or All/Four-Wheel Drive automobiles are the main focus of this topic. But whichever the case may be, they all have one thing in common: the axle housing is firmly attached to the rest of the vehicle employing the suspension system.

And this is where the Russians from Garage 54 decided the tried and tested solution might use an upgrade. Being who they are, it’s highly likely to expect something at least out of the ordinary, if not downright mind-bending. Because the traditional suspended design is all too apparent in its functioning principle and its mechanics are pretty straightforward to understand, a more puzzling alternative is their preferred workaround.

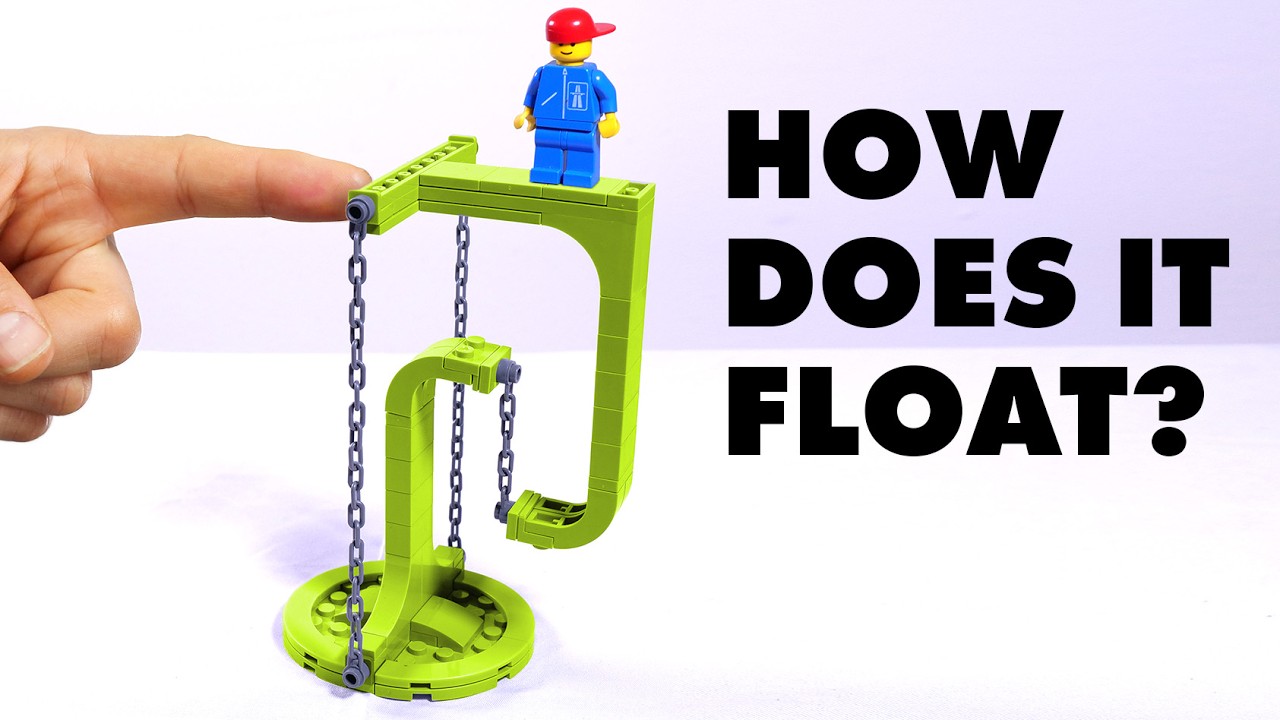

Enter Buckminster Fuller and his brain-fracturing concept of ‘tensional integrity.’ According to its definition, the notion can be translated as ‘the characteristic property of a stable three-dimensional structure consisting of members under tension that are contiguous and members under compression that are not.’ In other words, ‘is a design principle that applies when a discontinuous set of compression elements is opposed and balanced by a continuous tensile force, thereby creating an internal prestress that stabilizes the entire structure.’

If none of the above makes sense, then look at the second video for a detailed, visually intuitive explanation of how vertically mounted two elements can form a rigid assembly using only flexible connectors (think ropes, wires, cables, chains, straps, and so on). The intriguing feature of the whole unit is that the upper part appears to float in mid-air.

What’s more mind-boggling is that the connecting wires seem to prevent the top half from flying upward. The grand magic about tensegrity is that it appears to defy physics so severely that it’s nearly unbelievable. And yet, it's pure science – and the famous architect Buckminster Fuller was the first to put it in practical applications.

However, even the daring genius didn’t think his idea would be suitable for automotive uses – and the least of it was to replace the suspension on a rear-wheel drive Lada from Novosibirsk, Siberia. That’s Planet Russia, in case you’re wondering what the cradle of these far-reaching ideas of technological prowess and progress is.

The ‘I Don’t Like Rules’ gang from Garage 54 is a band of lively chaps who like to challenge the limits of motoring to the point where they break them, and we’ve reported about some of their deeds in the past. While some of their ideas are wild and hilarious, others bear the seeds of a paradigm-shifting genius.

I tend to put the latest experiment they underwent into the latter category. After all, everything is impossible until someone does it, which becomes commonplace. What they’ve done is replace the traditional rear suspension of their guinea-pig-Lada with a tensegrity assembly using steel chains and SHS (Square Hollow Section) tubing welded together. Say goodbye to floating axles and welcome the levitating axle instead.

Play the video to see exactly how they’ve done the seemingly impossible: their tensegrity Lada not only does not collapse, but it drives. That’s not to say it’s laser-straight due to the crude engineering of the contraption, but it proves a point and makes the entire concept feasible. The car holds its own, but due to the inherent flexibility of the chains keeping it upright, the vehicle sways continuously. Well, either that or the axle zig-zags under the body, but that’s a matter of physics perspective.

I enjoy practical experiments like these to the extent that I give the Siberian mechanics their deserved credit for this achievement. I suspect that, at one point, they’ll return to the project and improve it – they’ve done it in the past more than once, with remarkable results. I’m not (yet) convinced that a tensegrity suspension system will become the industry norm.

On the other hand, we should remember that more radical transformations than this have been implemented in self-propelled transportation over its 135-year-short history. Look no further than the steering wheel – it looks as if it’s been there since the first motorwagon took to the roads. To say nothing about the four-wheel architecture that is as widespread as it gets.

So don’t be too surprised if, sometime in the future, we won’t need springs and dampers but use who-knows-what super-strong strings to soften the ride. After all, if NASA played with the idea of building landing systems for space-exploring vehicles using tensegrity, why shouldn’t we put them to good use here?

And this is where the Russians from Garage 54 decided the tried and tested solution might use an upgrade. Being who they are, it’s highly likely to expect something at least out of the ordinary, if not downright mind-bending. Because the traditional suspended design is all too apparent in its functioning principle and its mechanics are pretty straightforward to understand, a more puzzling alternative is their preferred workaround.

Enter Buckminster Fuller and his brain-fracturing concept of ‘tensional integrity.’ According to its definition, the notion can be translated as ‘the characteristic property of a stable three-dimensional structure consisting of members under tension that are contiguous and members under compression that are not.’ In other words, ‘is a design principle that applies when a discontinuous set of compression elements is opposed and balanced by a continuous tensile force, thereby creating an internal prestress that stabilizes the entire structure.’

What’s more mind-boggling is that the connecting wires seem to prevent the top half from flying upward. The grand magic about tensegrity is that it appears to defy physics so severely that it’s nearly unbelievable. And yet, it's pure science – and the famous architect Buckminster Fuller was the first to put it in practical applications.

However, even the daring genius didn’t think his idea would be suitable for automotive uses – and the least of it was to replace the suspension on a rear-wheel drive Lada from Novosibirsk, Siberia. That’s Planet Russia, in case you’re wondering what the cradle of these far-reaching ideas of technological prowess and progress is.

I tend to put the latest experiment they underwent into the latter category. After all, everything is impossible until someone does it, which becomes commonplace. What they’ve done is replace the traditional rear suspension of their guinea-pig-Lada with a tensegrity assembly using steel chains and SHS (Square Hollow Section) tubing welded together. Say goodbye to floating axles and welcome the levitating axle instead.

Play the video to see exactly how they’ve done the seemingly impossible: their tensegrity Lada not only does not collapse, but it drives. That’s not to say it’s laser-straight due to the crude engineering of the contraption, but it proves a point and makes the entire concept feasible. The car holds its own, but due to the inherent flexibility of the chains keeping it upright, the vehicle sways continuously. Well, either that or the axle zig-zags under the body, but that’s a matter of physics perspective.

On the other hand, we should remember that more radical transformations than this have been implemented in self-propelled transportation over its 135-year-short history. Look no further than the steering wheel – it looks as if it’s been there since the first motorwagon took to the roads. To say nothing about the four-wheel architecture that is as widespread as it gets.

So don’t be too surprised if, sometime in the future, we won’t need springs and dampers but use who-knows-what super-strong strings to soften the ride. After all, if NASA played with the idea of building landing systems for space-exploring vehicles using tensegrity, why shouldn’t we put them to good use here?