The whole automotive industry is affected by the chip shortage that hit the world after 2020. Despite efforts, the precious pieces of silicon are still hard to find, and the plans to expand existing factories will not change the situation in the next two years at least. But there is another thing that the chip makers can do to alleviate the global chip shortage: improve the production yields.

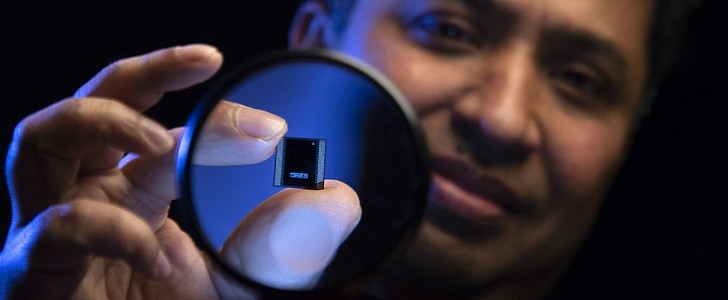

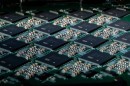

If you were not aware, a lot of chips produced today are junk material and are usually discarded before they are even packaged. This happens because of the imperfections in the silicon wafers used to make the chips. These are the big disks of semiconductors from which the electronic chips are fabricated. After the chips are imprinted into the wafer, this is cut into small pieces, each one being a chip. Not all chips cut from the same wafer are working or operating as desired, which lowers semiconductor yield while increasing the production costs.

One of the most important causes of low production yields in chip manufacturing is the fact that the silicon wafers don’t have a uniform thickness. This is exactly where the chip makers can improve the fabrication process to allow for more chips to be usable. Luckily, a team at the Nanyang Technological University (NTU) of Singapore has found the missing link that allows achieving just that.

The new technique is based on the nano transfer printing technology, a process that uses a polymer mold to print metal onto a substrate through pressure. It is a technique that has been used before but with a chemical adhesive layer that causes surface defects and performance degradation when printed at scale, besides being hazardous to human health. These are the reasons why this technology has not been adopted for mass production.

But the NTU researchers have developed a chemical-free printing technique that resulted in highly uniform and scalable semiconductor wafers. The nano transfer printing is accomplished by transferring gold nanostructure layers onto a silicon substrate at a relatively low temperature (160 C/320 F) to form a highly uniform wafer. The bonding is achieved by triggering direct chemisorption of the thin metal films under heat – a chemical reaction that creates a strong bond between the substrate surface and the substance that is adsorbed.

The resulting wafer is almost defect-free, which means that little to no chips are discarded due to poor performance. The lab results show that more than 99% of the chips produced using this technique are usable. Although the new method was only tested in the lab, the NTU researchers believe that it can be easily scaled for mass production by chipmakers like Samsung, Intel, or GlobalFoundries.

One of the most important causes of low production yields in chip manufacturing is the fact that the silicon wafers don’t have a uniform thickness. This is exactly where the chip makers can improve the fabrication process to allow for more chips to be usable. Luckily, a team at the Nanyang Technological University (NTU) of Singapore has found the missing link that allows achieving just that.

The new technique is based on the nano transfer printing technology, a process that uses a polymer mold to print metal onto a substrate through pressure. It is a technique that has been used before but with a chemical adhesive layer that causes surface defects and performance degradation when printed at scale, besides being hazardous to human health. These are the reasons why this technology has not been adopted for mass production.

But the NTU researchers have developed a chemical-free printing technique that resulted in highly uniform and scalable semiconductor wafers. The nano transfer printing is accomplished by transferring gold nanostructure layers onto a silicon substrate at a relatively low temperature (160 C/320 F) to form a highly uniform wafer. The bonding is achieved by triggering direct chemisorption of the thin metal films under heat – a chemical reaction that creates a strong bond between the substrate surface and the substance that is adsorbed.

The resulting wafer is almost defect-free, which means that little to no chips are discarded due to poor performance. The lab results show that more than 99% of the chips produced using this technique are usable. Although the new method was only tested in the lab, the NTU researchers believe that it can be easily scaled for mass production by chipmakers like Samsung, Intel, or GlobalFoundries.