Emissions standards are a constant struggle between improving air quality, current technology, and costs. As the years go by, the laws become more strict, and automakers have to invest more in developing cleaner cars.

The first European emissions norm was mandatory for all new passenger cars registered starting the first calendar day of 1993. It was called Euro 1, and its purpose was to stop the launch of new vehicles without any emission control devices. Its successor came four years later, and was named Euro 2.

The change introduced by Euro 2 cut the sum of hydrocarbons and nitrogen oxides to half of the allowed limit for Euro 1 in the case of gasoline-powered passenger cars. Euro 3 was a stricter standard from the way it measured emissions, which involved less time for engines to heat up before being tested.

It was replaced in 2006 on the mandatory list with Euro 4 for gasoline engines, which allowed half the emission levels authorized by the previous standard for gasoline engines.

Euro 3 also enforced a separation of hydrocarbons and nitrogen oxides, which were also reduced by Euro 4 to half of the allowance of the previous norm.

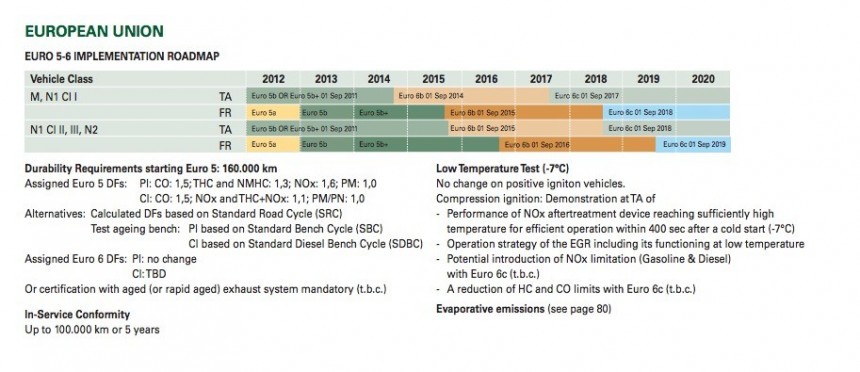

The first day of Euro 5 mandatory for new registrations was January 1, 2011. Gasoline-engined cars had a lower threshold of maximum nitrogen oxide emissions, as well as less non-methane hydrocarbons, which was a new addition to the norm. CO2 and hydrocarbon criteria were not modified.

The first day of September 2015 brought the introduction of Euro 6 for gasoline and diesel engines. It remained virtually unchanged for gasoline engines, but it brought a new measurement and maximum level — particle number, and only direct-injected engines have to comply with the norm.

The next level is called Euro 6c, and it has become mandatory for all new gasoline engines registered in Europe starting September 1, 2018. The new restrictions introduced with Euro 6c will also involve reducing the particle number. In short, the new limit means allowing ten times fewer particles than the previous phase of Euro 6, which is currently called Euro 6b.

In the case of diesel engines, emissions standards have become more and more strict over the years, following a rate similar to that used for gasoline engines.

While modern diesel engines have reduced particulate emissions, they have to deal with lowering the emissions of NOx, which represent nitrogen oxide gas, a harmful chemical.

With the introduction regarding emissions norms complete, it is time to see the challenges faced by automakers when developing new engines and the cars that will use them as powerplants.

This article will only focus on the problems brought to passenger vehicles, and the challenges faced in Europe also affect the vehicles sold in the USA, as they operate on the same principle and will have to comply with even stricter terms.

One of the first problems that were discovered after years of use and real-world testing was that direct injection systems on gasoline engines are not as clean as they were supposed to be.

While the solution provides better fuel economy, increased performance, and more precision when placing fuel in the combustion chamber, it has brought troubles for some automakers.

First of all, gasoline direct injected engines are prone to carbon buildup in the top end, especially with the valves. It is not a general problem, fortunately, but it can affect drivability in more ways than you might think, going from misfires to turbocharger problems and even damaging the catalytic converter.

At first, the carbon buildup was blamed on poor quality fuel, but the main cause is the fact that the mist of gasoline that was sprayed on the backs of intake valves kept things clean, along with the intake ports.

Unfortunately, valve timing settings and direct injection have led to an increase in these cases, but one cannot definitively say that they will happen to all cars with direct injected gasoline engines.

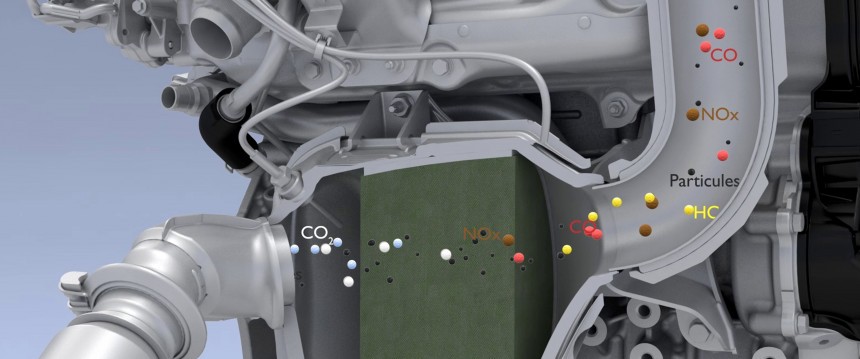

Both gasoline and diesel engines had to receive advanced filters to keep emissions low. Among them is the particulate filter, which was employed on diesel engines.

Today, adding a particulate filter to most diesel engines is not enough to attain Europe’s environmental norms, so automakers had to devise other emission control systems, from SCR to closed-loop NOx traps.

Recently, automakers have begun considering adding particulate filters to gasoline engines, because the new generation of direct injection units also has to comply with particulate regulations. This has brought a new challenge to engineers, who have to get these units to comply with the law, while costs have to be kept down.

Regardless of the expense of a particulate filter for an automaker, the development of the new engines will have to be paid by someone. While car makers reinvest some of their profit into this activity, consumers will eventually have to pay more to get cleaner cars. While this is upsetting, you must accept the fact that it is a necessary step to have cleaner air in our cities.

A few years ago, manufacturers decided to fit their cars with smaller turbocharged engines instead of larger naturally aspirated units. This trend was named downsizing, and it was applied to all areas of automotive development.

Smaller engines brought less weight than traditional units, even with the added components for a turbocharger, while fuel economy was improved in theory.

Unfortunately, not all downsized engines were more efficient than their naturally aspirated counterparts. Sure, horsepower was increased, and torque has reached figures that were unattainable for the naturally aspirated units they replaced.

However, fuel economy was only improved for those that drove in an economical manner for each of their trips, and even that proved to be less efficient than some naturally aspirated gasoline engines.

Recently, a study has shown that downsized engines struggle to match real world economy and emissions figures of naturally aspirated units with a bigger capacity.

With years and billions invested in downsizing, automakers will have to keep improving those engines. We do not see a potential return of naturally aspirated gasoline engines for most brands that had downsized their power plants.

Back in the day, a naturally aspirated engine was almost bulletproof. All the user had to do was drive it gently until it warmed up, and perform regular maintenance according to manufacturer recommendations.

Over the years, downsized engines brought more components and complexity, and the average Joe might not be as careful as drivers should be around turbocharged units.

Over time, these problems make consumers fear turbocharged units, even though most of them are engineered to be just as reliable as naturally aspirated engines.

All you have to do is to respect the maintenance schedule and never drive it hard until the engine has warmed up to operating temperature. Remember, idling in the parking lot is not the way of warming up an engine, stop doing that.

The increased complexity of engines also affects emission control systems, which tend to be sensitive because of the rare metals they use. Even the oldest catalytic converters were prone to failure if unburnt fuel reached them, and things have taken a twist for the worse with particulate filters, which have to perform regular “regenerations.”

The latter procedure is not always disclosed in the gauge cluster, and most users do not know how to identify it by the change in engine note. The moral of this chapter is that these engines require more care when operating, and servicing must be made at scheduled intervals to keep the cars running in optimal condition.

Not long after Euro 6c will become mandatory for all newly registered cars in Europe, automakers will have to test their models through the WLTP, which is short for Worldwide harmonized Light vehicles Test Procedures. The method is developed by multiple countries to test real driving emissions, along with real-world fuel economy.

After years and years of calibrating their vehicles to attain a balance between real-world fuel economy and the best possible results in laboratory-performed emissions and fuel economy tests, automakers will have to configure their cars for the new WLTP cycle.

The test procedure will keep using rolling roads instead of public roads, but it will simulate real world conditions using new guidelines for ambient temperature, tire selection and pressure, motion resistance of the rolling road, and three testing cycles that will be applied.

A real-world driving test is also in the cards for the cars of the future. Automakers like PSA Peugeot-Citroen and Opel have vouched to voluntarily provide real world fuel economy results for their existing cars before it becomes mandatory.

It will be costly for automakers to perfect their models to suit the new legislation, but buyers will benefit in the form of more efficient and cleaner vehicles on the road. Evidently, they will come at a bigger retail price, which nobody can predict today.

The change introduced by Euro 2 cut the sum of hydrocarbons and nitrogen oxides to half of the allowed limit for Euro 1 in the case of gasoline-powered passenger cars. Euro 3 was a stricter standard from the way it measured emissions, which involved less time for engines to heat up before being tested.

It was replaced in 2006 on the mandatory list with Euro 4 for gasoline engines, which allowed half the emission levels authorized by the previous standard for gasoline engines.

Euro 3 also enforced a separation of hydrocarbons and nitrogen oxides, which were also reduced by Euro 4 to half of the allowance of the previous norm.

The first day of Euro 5 mandatory for new registrations was January 1, 2011. Gasoline-engined cars had a lower threshold of maximum nitrogen oxide emissions, as well as less non-methane hydrocarbons, which was a new addition to the norm. CO2 and hydrocarbon criteria were not modified.

The first day of September 2015 brought the introduction of Euro 6 for gasoline and diesel engines. It remained virtually unchanged for gasoline engines, but it brought a new measurement and maximum level — particle number, and only direct-injected engines have to comply with the norm.

In the case of diesel engines, emissions standards have become more and more strict over the years, following a rate similar to that used for gasoline engines.

While modern diesel engines have reduced particulate emissions, they have to deal with lowering the emissions of NOx, which represent nitrogen oxide gas, a harmful chemical.

With the introduction regarding emissions norms complete, it is time to see the challenges faced by automakers when developing new engines and the cars that will use them as powerplants.

This article will only focus on the problems brought to passenger vehicles, and the challenges faced in Europe also affect the vehicles sold in the USA, as they operate on the same principle and will have to comply with even stricter terms.

Direct gasoline injection systems generate more particles

While the solution provides better fuel economy, increased performance, and more precision when placing fuel in the combustion chamber, it has brought troubles for some automakers.

First of all, gasoline direct injected engines are prone to carbon buildup in the top end, especially with the valves. It is not a general problem, fortunately, but it can affect drivability in more ways than you might think, going from misfires to turbocharger problems and even damaging the catalytic converter.

At first, the carbon buildup was blamed on poor quality fuel, but the main cause is the fact that the mist of gasoline that was sprayed on the backs of intake valves kept things clean, along with the intake ports.

Unfortunately, valve timing settings and direct injection have led to an increase in these cases, but one cannot definitively say that they will happen to all cars with direct injected gasoline engines.

Emissions treatment system are expensive

Today, adding a particulate filter to most diesel engines is not enough to attain Europe’s environmental norms, so automakers had to devise other emission control systems, from SCR to closed-loop NOx traps.

Recently, automakers have begun considering adding particulate filters to gasoline engines, because the new generation of direct injection units also has to comply with particulate regulations. This has brought a new challenge to engineers, who have to get these units to comply with the law, while costs have to be kept down.

Regardless of the expense of a particulate filter for an automaker, the development of the new engines will have to be paid by someone. While car makers reinvest some of their profit into this activity, consumers will eventually have to pay more to get cleaner cars. While this is upsetting, you must accept the fact that it is a necessary step to have cleaner air in our cities.

Downsizing has not worked out, studies say

Smaller engines brought less weight than traditional units, even with the added components for a turbocharger, while fuel economy was improved in theory.

Unfortunately, not all downsized engines were more efficient than their naturally aspirated counterparts. Sure, horsepower was increased, and torque has reached figures that were unattainable for the naturally aspirated units they replaced.

However, fuel economy was only improved for those that drove in an economical manner for each of their trips, and even that proved to be less efficient than some naturally aspirated gasoline engines.

Recently, a study has shown that downsized engines struggle to match real world economy and emissions figures of naturally aspirated units with a bigger capacity.

With years and billions invested in downsizing, automakers will have to keep improving those engines. We do not see a potential return of naturally aspirated gasoline engines for most brands that had downsized their power plants.

Reliability can be a problem

Over the years, downsized engines brought more components and complexity, and the average Joe might not be as careful as drivers should be around turbocharged units.

Over time, these problems make consumers fear turbocharged units, even though most of them are engineered to be just as reliable as naturally aspirated engines.

All you have to do is to respect the maintenance schedule and never drive it hard until the engine has warmed up to operating temperature. Remember, idling in the parking lot is not the way of warming up an engine, stop doing that.

The increased complexity of engines also affects emission control systems, which tend to be sensitive because of the rare metals they use. Even the oldest catalytic converters were prone to failure if unburnt fuel reached them, and things have taken a twist for the worse with particulate filters, which have to perform regular “regenerations.”

The latter procedure is not always disclosed in the gauge cluster, and most users do not know how to identify it by the change in engine note. The moral of this chapter is that these engines require more care when operating, and servicing must be made at scheduled intervals to keep the cars running in optimal condition.

The biggest setback for some automakers

After years and years of calibrating their vehicles to attain a balance between real-world fuel economy and the best possible results in laboratory-performed emissions and fuel economy tests, automakers will have to configure their cars for the new WLTP cycle.

The test procedure will keep using rolling roads instead of public roads, but it will simulate real world conditions using new guidelines for ambient temperature, tire selection and pressure, motion resistance of the rolling road, and three testing cycles that will be applied.

A real-world driving test is also in the cards for the cars of the future. Automakers like PSA Peugeot-Citroen and Opel have vouched to voluntarily provide real world fuel economy results for their existing cars before it becomes mandatory.

It will be costly for automakers to perfect their models to suit the new legislation, but buyers will benefit in the form of more efficient and cleaner vehicles on the road. Evidently, they will come at a bigger retail price, which nobody can predict today.