Spaceships are perhaps the most impressive pieces of machinery made by our species. Designed to go into outer space, where no living thing we know of can exist unprotected, spaceships are also the vehicles that will take our kind to the star, expanding humanity's reach far beyond the borders of our planet. But for that to happen we'll need a lot of spaceships.

The way things are now, spacecraft are being built to serve a set number of missions. That means there is no production line that spits them out in a constant stream, and new ones are built only after the previous versions have been discarded.

That's a business model that works because, at the moment, we don't have a very large pool of people going to space on a regular basis. But if this whole space tourism idea catches on and becomes more affordable, our reality will change dramatically.

Virgin Galactic is one of the companies in the space tourism business. It offers rather expensive ($450,000 per ticket) and extremely short (up to five minutes) trips just into the realm of zero-g, but despite all that, it seems pretty confident customers will flow in the not-so-distant future.

The company conducted six passenger flights so far, and it's gearing up for the seventh in early June. For all these trips it used a single spacecraft, the VSS Unity. It's the second spacecraft in the Virgin portfolio of SpaceShipTwo-class machines (the first one, VSS Enterprise, crashed during tests in 2014), but it will certainly not be the last one.

It's likely, though, that it will be the last with this particular design. That's because Virgin Galactic is working on a new ship design called Delta class. It will be larger and capable of accommodating more people (six instead of four on the Unity), but more importantly, it will be tailored to support high-production volumes.

Virgin plans to complete the Delta ships at a production facility in Phoenix, Arizona. In fact, plans were for the factory to be up and running back in 2023, but that, obviously, did not happen.

The company did take a step in the right direction this week, when it announced the opening of a new system integration facility. Located in Southern California, the facility will be used by Virgin to put Delta's main components through their paces before clearing them for flight.

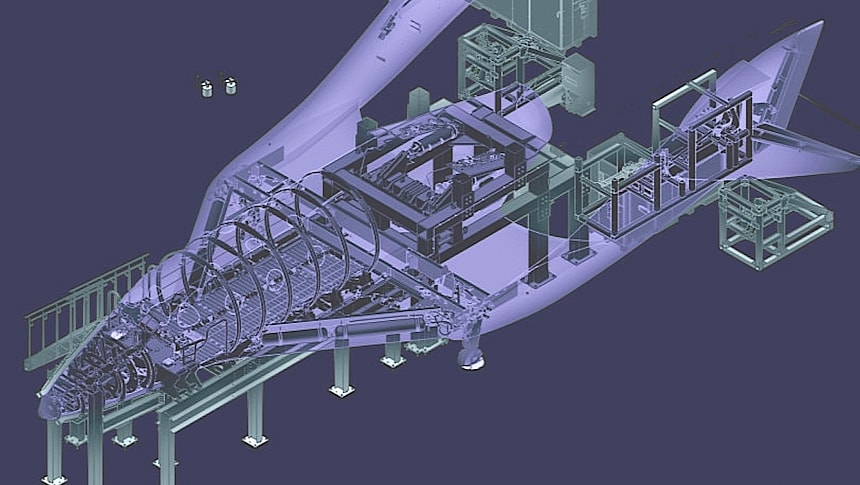

To do that the crews of engineers rely on a test platform known as the Iron Bird. The system allows elements such as avionics, feather actuation, pneumatics and hydraulics to be tested before going into the actual ships.

Iron Bird's subsystems have already been installed and Virgin says the rest of the components will be added over the course of the year. But it's not the only test rig the company will use in the Delta program.

Another piece of hardware, a static test article, will be used to verify the structural integrity and load limits of the ships, but also to determine the final design.

Using this method has the company's higher-ups confident that they'll shave “years off the development timeline" when compared to the VSS Unity.

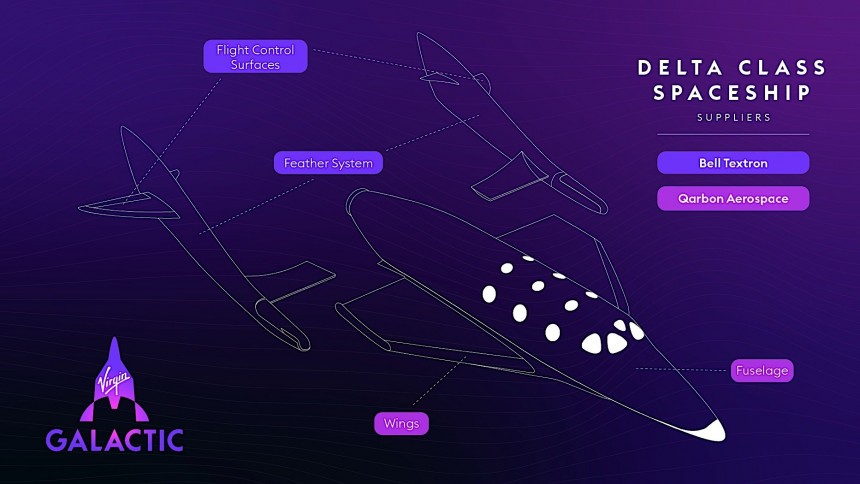

The Delta ships will be roughly the same in terms of design as the Unity, down to the impressive and unique wing feathering system that allows it to reach space and then come back. They are being put together by Virgin with help from other companies.

Aerospace company Bell is working on designing the feathering tech for this class of spacecraft, and it was also tasked with developing the control surfaces. Qarbon Aerospace, a maker of composite components, has been tasked with producing the fuselage and wing. On its end, Virgin itself will handle overall system architecture, design, integration, and final assembly.

Separately, the carrier plane of the VSS Unity, VMS Eve, will be replaced as well, with Boeing's Aurora Flight Sciences already working on a new design – this one is expected to be completed in 2025.

We have no actual indication of how many Deltas the company is planning, but we were promised at some point in the past a whole fleet of them. For starters, though, two will be made and each of the ships will be capable of performing eight space flights each month, increasing the monthly capacity of the VSS Unity by no less than 12 times.

That translates into no less than 750 paying customers and an annual revenue of $450 million, a sum that would finally put Virgin Galactic on a path to profitability.

We're told the production lines for the Delta ships, probably the world's first mass-production ones for space-faring vehicles, should begin rolling soon, because commercial flights are expected to start just two years from now.

I'm inclined to tell you to take that deadline with a grain of salt, but Virgin Galactic stated this week it is on track to achieve that target.

That's a business model that works because, at the moment, we don't have a very large pool of people going to space on a regular basis. But if this whole space tourism idea catches on and becomes more affordable, our reality will change dramatically.

Virgin Galactic is one of the companies in the space tourism business. It offers rather expensive ($450,000 per ticket) and extremely short (up to five minutes) trips just into the realm of zero-g, but despite all that, it seems pretty confident customers will flow in the not-so-distant future.

The company conducted six passenger flights so far, and it's gearing up for the seventh in early June. For all these trips it used a single spacecraft, the VSS Unity. It's the second spacecraft in the Virgin portfolio of SpaceShipTwo-class machines (the first one, VSS Enterprise, crashed during tests in 2014), but it will certainly not be the last one.

It's likely, though, that it will be the last with this particular design. That's because Virgin Galactic is working on a new ship design called Delta class. It will be larger and capable of accommodating more people (six instead of four on the Unity), but more importantly, it will be tailored to support high-production volumes.

The company did take a step in the right direction this week, when it announced the opening of a new system integration facility. Located in Southern California, the facility will be used by Virgin to put Delta's main components through their paces before clearing them for flight.

To do that the crews of engineers rely on a test platform known as the Iron Bird. The system allows elements such as avionics, feather actuation, pneumatics and hydraulics to be tested before going into the actual ships.

Iron Bird's subsystems have already been installed and Virgin says the rest of the components will be added over the course of the year. But it's not the only test rig the company will use in the Delta program.

Another piece of hardware, a static test article, will be used to verify the structural integrity and load limits of the ships, but also to determine the final design.

Using this method has the company's higher-ups confident that they'll shave “years off the development timeline" when compared to the VSS Unity.

The Delta ships will be roughly the same in terms of design as the Unity, down to the impressive and unique wing feathering system that allows it to reach space and then come back. They are being put together by Virgin with help from other companies.

Separately, the carrier plane of the VSS Unity, VMS Eve, will be replaced as well, with Boeing's Aurora Flight Sciences already working on a new design – this one is expected to be completed in 2025.

We have no actual indication of how many Deltas the company is planning, but we were promised at some point in the past a whole fleet of them. For starters, though, two will be made and each of the ships will be capable of performing eight space flights each month, increasing the monthly capacity of the VSS Unity by no less than 12 times.

That translates into no less than 750 paying customers and an annual revenue of $450 million, a sum that would finally put Virgin Galactic on a path to profitability.

We're told the production lines for the Delta ships, probably the world's first mass-production ones for space-faring vehicles, should begin rolling soon, because commercial flights are expected to start just two years from now.

I'm inclined to tell you to take that deadline with a grain of salt, but Virgin Galactic stated this week it is on track to achieve that target.