The Space Shuttle, despite two very traumatizing accidents, is without a doubt one of our species' most successful family of otherworldly vehicles. Introduced in 1981, the family flew a total of 135 space missions, carrying off this planet and bringing back over the years a total of 355 astronauts.

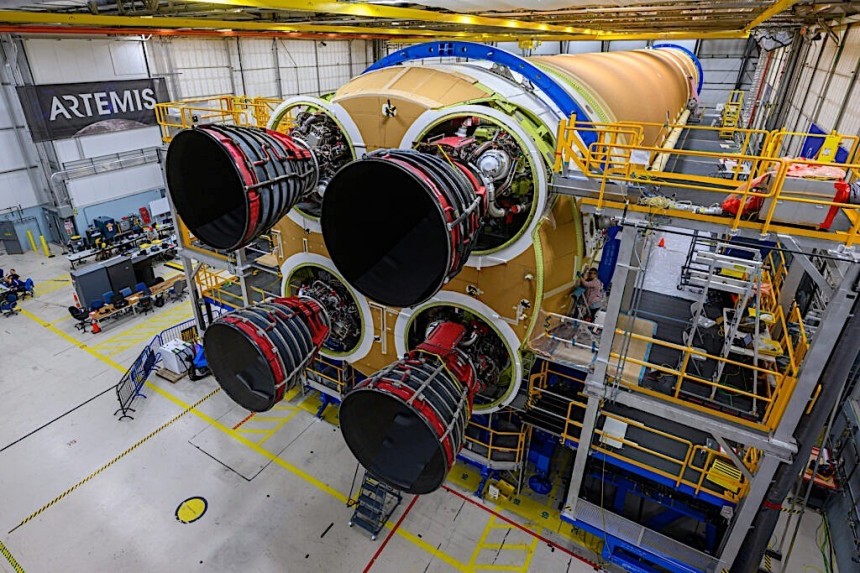

The key elements that made the shuttle successful was its engines. Produced by a company called Aerojet Rocketdyne, they were called RS-25, or Space Shuttle Main Engine (SSME). Three of them were installed at the back of the orbiter, generating a combined thrust of 1.2 million pounds while burning liquid propellant.

When the final Space Shuttle flight concluded in 2011, both Aerojet Rocketdyne and NASA decided not to throw away the most important bits, and they set aside 16 RS-25 engines for potential further use.

The engines were stored away and stayed so until NASA started looking for power units for the mighty Space Launch System (SLS) rocket it planned for what was to become known as the Artemis Moon exploration program.

The space agency settled on this type of hardware for several reasons, including the fact it was "the most reliable, efficient, high-performance engines ever built." Naturally, they had to be modified to be able to fly on the SLS, so modification work on them started back in 2015.

Alongside the stored RS-25s, NASA also decided to use engines that had flown before. On the Artemis I mission, which departed our planet at the end of 2022, the mega-rocket was pushed off the ground by 8.8 million pounds of thrust coming from a pair of solid rocket boosters and four RS-25 engines strapped to the core stage.

These engines were not new but had been previously flown on the Space Shuttle, helping put together the International Space Station (ISS) and deploy the Hubble Space Telescope. Even so, they worked flawlessly.

For Artemis II, which at the time of writing is scheduled to lift off in 2025, NASA will use a combo of four RS-25 engines. Two of them have powered space shuttles, with one of them displaying no less than 15 missions under its belt. The other two RS-25s will be brand new, with newly produced ones to be used exclusively in the Moon exploration program, starting with the Artemis V mission scheduled for 2029.

That's right, Aerojet Rocketdyne is back at it producing RS-25s. Because of the advancements made since the first one rolled off the lines decades ago, the new ones are made using both new components (including nozzle, hydraulic actuators, flex ducts, and turbopumps) and manufacturing methods (like, say 3D printing), and that means the end product requires additional testing.

NASA began putting the brand-new space shuttle engines to the test in October 2023, and rapidly moved through no less than 12 tests that successfully concluded at the beginning of April.

All tests were performed as per a "test like you fly" approach, meaning the RS-25s had to keep burning for at least 500 seconds, which is how much they are expected to operate during a real-life launch. During three of the runs the powerplants were kept on for 600 seconds, and one even for as much as 650 seconds, just to see what happens.

In all, the 12 RS-25 tests amounted to 6,465 seconds of burn time, which would be the equivalent of 12 SLS launches. Power levels during the procedures varied from 80 to 113 percent – in real life, the new engines will have to operate at 111 percent.

All the testing was done at the Stennis Space Center in Mississippi and is hailed by NASA as "a key step for lead engines contractor Aerojet Rocketdyne to build new RS-25 engines, using modern processes and manufacturing techniques."

The new methods not only translate into more reliable engines but also reduce the cost of making them. Despite inflation and more expensive parts, NASA says the RS-25s are cheaper to produce than the Space Shuttle-era ones by as much as 30 percent. For reference, the cost of such a unit was of about $40 million.

There is no set date on when Aerojet Rocketdyne will start manufacturing the new engines, but NASA needs a lot of them. More to the point, it requested a total of 24 engines, which should be enough for the needs of Artemis missions V through IX.

A key aspect of using the RS-25 tech on the SLS is that of reusability. Although the engines were fully reusable on the Space Shuttle (after all, the spaceship came back down and landed with crew on board), the same cannot be said for the SLS.

That's because when it comes to the Moon rocket, not a single component is reusable - and it makes the 30 percent price cut compared to the previous engine version make a lot of sense, as no one is pleased throwing millions out the window, not even for space exploration purposes.

When the final Space Shuttle flight concluded in 2011, both Aerojet Rocketdyne and NASA decided not to throw away the most important bits, and they set aside 16 RS-25 engines for potential further use.

The engines were stored away and stayed so until NASA started looking for power units for the mighty Space Launch System (SLS) rocket it planned for what was to become known as the Artemis Moon exploration program.

The space agency settled on this type of hardware for several reasons, including the fact it was "the most reliable, efficient, high-performance engines ever built." Naturally, they had to be modified to be able to fly on the SLS, so modification work on them started back in 2015.

Alongside the stored RS-25s, NASA also decided to use engines that had flown before. On the Artemis I mission, which departed our planet at the end of 2022, the mega-rocket was pushed off the ground by 8.8 million pounds of thrust coming from a pair of solid rocket boosters and four RS-25 engines strapped to the core stage.

These engines were not new but had been previously flown on the Space Shuttle, helping put together the International Space Station (ISS) and deploy the Hubble Space Telescope. Even so, they worked flawlessly.

That's right, Aerojet Rocketdyne is back at it producing RS-25s. Because of the advancements made since the first one rolled off the lines decades ago, the new ones are made using both new components (including nozzle, hydraulic actuators, flex ducts, and turbopumps) and manufacturing methods (like, say 3D printing), and that means the end product requires additional testing.

NASA began putting the brand-new space shuttle engines to the test in October 2023, and rapidly moved through no less than 12 tests that successfully concluded at the beginning of April.

All tests were performed as per a "test like you fly" approach, meaning the RS-25s had to keep burning for at least 500 seconds, which is how much they are expected to operate during a real-life launch. During three of the runs the powerplants were kept on for 600 seconds, and one even for as much as 650 seconds, just to see what happens.

In all, the 12 RS-25 tests amounted to 6,465 seconds of burn time, which would be the equivalent of 12 SLS launches. Power levels during the procedures varied from 80 to 113 percent – in real life, the new engines will have to operate at 111 percent.

All the testing was done at the Stennis Space Center in Mississippi and is hailed by NASA as "a key step for lead engines contractor Aerojet Rocketdyne to build new RS-25 engines, using modern processes and manufacturing techniques."

There is no set date on when Aerojet Rocketdyne will start manufacturing the new engines, but NASA needs a lot of them. More to the point, it requested a total of 24 engines, which should be enough for the needs of Artemis missions V through IX.

A key aspect of using the RS-25 tech on the SLS is that of reusability. Although the engines were fully reusable on the Space Shuttle (after all, the spaceship came back down and landed with crew on board), the same cannot be said for the SLS.

That's because when it comes to the Moon rocket, not a single component is reusable - and it makes the 30 percent price cut compared to the previous engine version make a lot of sense, as no one is pleased throwing millions out the window, not even for space exploration purposes.