The electric vehicle industry is rapidly booming, and brands must find a way to constantly evolve and keep their technologies up to date or even innovate. Sometimes, it's hard for a company to do so independently, so it's critical to form partnerships that enable technological advancements. McLaren Applied and in-wheel motor specialists Elaphe have announced a collaboration that aims to help auto manufacturers improve overall EV performance.

McLaren Applied initially started with the name "McLaren Composites" and as a subsidiary of McLaren Group. Its main work was manufacturing parts for the McLaren F1 and Mercedes-Benz SLR McLaren supercars. But it also obtained contracts for other companies and moved into the energy industry. In 2021, the company was sold to Greybull Capital.

Elaphe Propulsion Technologies is the producer and developer of high-tech propulsion technology. According to the company's website, its founder was the first to design a high-torque motor center around direct-drive automotive applications. It was founded in 2006 with the mission of introducing in-wheel powertrain solutions to the automotive industry.

Elaphe prides itself in developing the world's highest-performance in-wheel-powered applications to date, such as in-wheel-driven SUVs and supercars. It currently has three direct-drive in-wheel motors available. For instance, one of the vehicles that will feature its technology is the Aptera Delta, a solar trike.

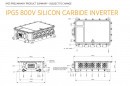

One of the newer innovations coming from the company is the IPG5 800V silicon carbide Inverter, designed as a future-proof solution for electrification. The component delivers exceptional powertrain efficiency and supports fast charging. Over ten years of research have led to the creation of this fifth-generation inverter, with insights obtained from F1 technology development.

Long story short, the silicon carbide technology is designed to significantly increase the switching frequency, resulting in a faster, more efficient drivetrain with reduced weight and manufacturing costs.

The IPG5 is packed in a 3.79-liter box, weighs a mere 5.5 kg (12 lbs.) and is highly controllable, allowing variable switching frequencies up to 32 kHz and offers – according to the company – unparalleled motor response. The variable switching frequencies function enables manufacturers to run higher-speed motors that are smaller and lighter. Moreover, the IPG5 produces less heat, so the cooling system was downsized.

McLaren Applied describes efficiency as the next "wave" of electrification. According to the company, the first was pioneering the technology, followed by the current stage, the adoption of EVs at a mainstream level. Next up, we have efficiency and the use of silicon carbide (SiC) semiconductors, while the final and fourth stage focuses on drivability and adding character to the powertrains of EVs.

The IPG5, combined with Elaphe's range of in-wheel motors, will result in a highly efficient system with enhanced packaging and driving dynamics. Elaphe is looking to make the powertrain software-defined, so this new partnership will move the company closer to its goal.

Elaphe Propulsion Technologies is the producer and developer of high-tech propulsion technology. According to the company's website, its founder was the first to design a high-torque motor center around direct-drive automotive applications. It was founded in 2006 with the mission of introducing in-wheel powertrain solutions to the automotive industry.

Elaphe prides itself in developing the world's highest-performance in-wheel-powered applications to date, such as in-wheel-driven SUVs and supercars. It currently has three direct-drive in-wheel motors available. For instance, one of the vehicles that will feature its technology is the Aptera Delta, a solar trike.

One of the newer innovations coming from the company is the IPG5 800V silicon carbide Inverter, designed as a future-proof solution for electrification. The component delivers exceptional powertrain efficiency and supports fast charging. Over ten years of research have led to the creation of this fifth-generation inverter, with insights obtained from F1 technology development.

Long story short, the silicon carbide technology is designed to significantly increase the switching frequency, resulting in a faster, more efficient drivetrain with reduced weight and manufacturing costs.

The IPG5 is packed in a 3.79-liter box, weighs a mere 5.5 kg (12 lbs.) and is highly controllable, allowing variable switching frequencies up to 32 kHz and offers – according to the company – unparalleled motor response. The variable switching frequencies function enables manufacturers to run higher-speed motors that are smaller and lighter. Moreover, the IPG5 produces less heat, so the cooling system was downsized.

McLaren Applied describes efficiency as the next "wave" of electrification. According to the company, the first was pioneering the technology, followed by the current stage, the adoption of EVs at a mainstream level. Next up, we have efficiency and the use of silicon carbide (SiC) semiconductors, while the final and fourth stage focuses on drivability and adding character to the powertrains of EVs.

The IPG5, combined with Elaphe's range of in-wheel motors, will result in a highly efficient system with enhanced packaging and driving dynamics. Elaphe is looking to make the powertrain software-defined, so this new partnership will move the company closer to its goal.