South Korean carmakers were disadvantaged by the Biden administration’s Inflation Reduction Act. On the other hand, Korean battery producers are set to reap the benefits. LG Chem, which supplies battery cells to Tesla and General Motors, announced a $3 billion investment in a battery cathode plant in the U.S.

The new production facility in Tennessee is one of the biggest EV-related investments in the U.S. since the Inflation Reduction Act (IRA) was passed in August. According to the act, the U.S. government awards significant subsidies to companies that source the batteries and the critical components from the U.S. or an American free-trade partner. This puts the companies that don’t comply with IRA requirements at a cost disadvantage.

That’s why Korean carmakers Hyundai and Kia are hit especially hard, with incentives vanishing for their EVs under the IRA. Both carmakers will see a boost starting in 2025 when the Hyundai-Kia North American plant will start building electric vehicles. The same year, LG Chem’s new cathode plant in Tennessee is set to become operational, with an annual production capacity of 120,000 tonnes (132,300 tons) of cathode materials by 2027, enough to power about 1.2 million electric vehicles.

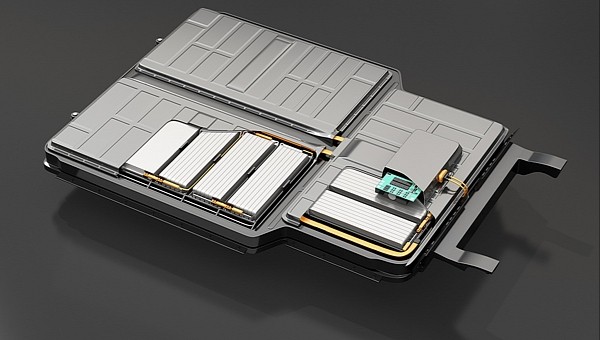

LG Chem is expected to supply cathode materials from the new plant to Ultium Cells, a battery joint venture between GM and LG Chem’s subsidiary LG Energy Solution. Tesla is also rumored among the beneficiaries, especially as the NCMA chemistry the new plant favors was also adopted by Tesla as part of its diversification plans.

NCMA stands for nickel, cobalt, manganese, and aluminum and designates nickel-rich battery chemistry with a high energy density. An important advantage of NCMA chemistry is the high nickel content of 90%, which reduces the need for cobalt, which is expensive and controversial to mine and refine. Not only that, but the new chemistry allows manufacturers to reduce their exposure to refining and processing in China. According to Benchmark Mineral Intelligence, China currently refines 75% of the world’s cobalt.

That’s why Korean carmakers Hyundai and Kia are hit especially hard, with incentives vanishing for their EVs under the IRA. Both carmakers will see a boost starting in 2025 when the Hyundai-Kia North American plant will start building electric vehicles. The same year, LG Chem’s new cathode plant in Tennessee is set to become operational, with an annual production capacity of 120,000 tonnes (132,300 tons) of cathode materials by 2027, enough to power about 1.2 million electric vehicles.

LG Chem is expected to supply cathode materials from the new plant to Ultium Cells, a battery joint venture between GM and LG Chem’s subsidiary LG Energy Solution. Tesla is also rumored among the beneficiaries, especially as the NCMA chemistry the new plant favors was also adopted by Tesla as part of its diversification plans.

NCMA stands for nickel, cobalt, manganese, and aluminum and designates nickel-rich battery chemistry with a high energy density. An important advantage of NCMA chemistry is the high nickel content of 90%, which reduces the need for cobalt, which is expensive and controversial to mine and refine. Not only that, but the new chemistry allows manufacturers to reduce their exposure to refining and processing in China. According to Benchmark Mineral Intelligence, China currently refines 75% of the world’s cobalt.