Hybrid powertrains have seen quite the popularity increase, with more and more automotive producers including this solutions in their offers.

One of the most recent hybrid powertrain applications on the market comes from Bosch. We are talking about the parallel full hybrid technology. This allows the car to be run on internal combustion, electric or combined power.

The parallel full hybrid layout can be used as a more cost-effective solution compared to other hybrid concepts. One of the reasons for this is the fact that it only uses one electric motor, which serves both as a motor and as a generator.

Bosch Parallel Full Hybrid

Bosch’s development has been used by the Volkswagen Group, for the hybrid versions of the VW Touareg and Porsche Cayenne. Bosch provides the electric motor, the power electronics and the special Motronic control unit, which governs both the electric and the internal combustion engine.

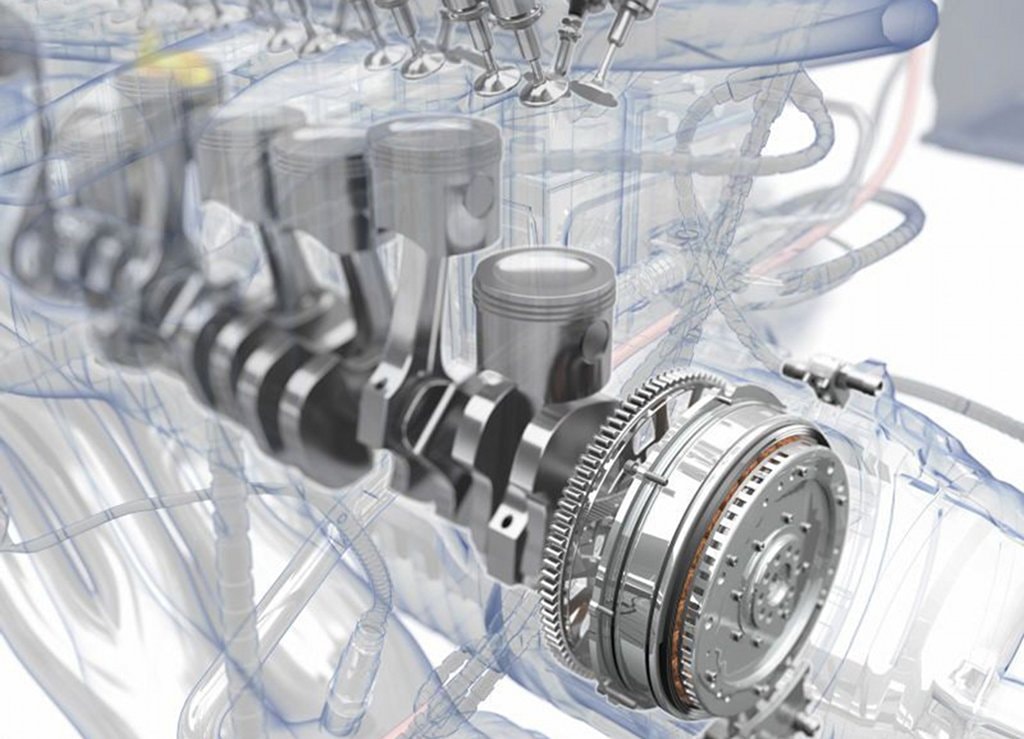

The engine used by VW is a direct-injection supercharged 3.0 liter V6 petrol unit, which is matted to an eight-speed automatic transmission. The powerplant delivers 33 hp and a maximum torque of 440 Nm.

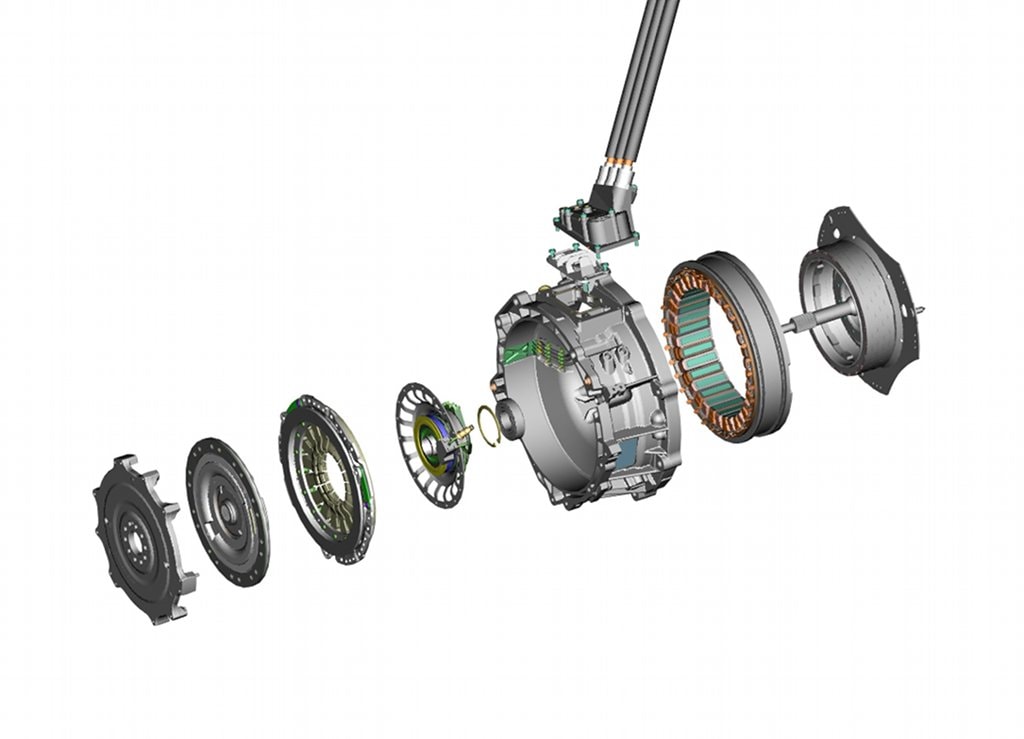

The electric motor used in the system is Bosch’s water-cooled Integrated Motor Generator (IMG), which comes with a separate clutch. The hybrid module is located between the internal combustion engine and the gearbox and requires a reduced amount of space, as it only has a diameter of 30 centimeters and a length of 145 mm.

The IMG develops 34 kW (46hp) and a maximum torque of 300 Nm, allowing the vehicle it is installed on to run at a speed of maximum 50 or 60 km/h (31 or 37 km/h) running exclusively on electric power. During the braking phase, the motor acts as a generator, recovering kinetic energy and converting it into electricity that is stored into the battery.

The system uses a nickel metal hybrid (NiMH) battery that has an energy capacity of 1.7 kWh, with a peak power of 288 volts.

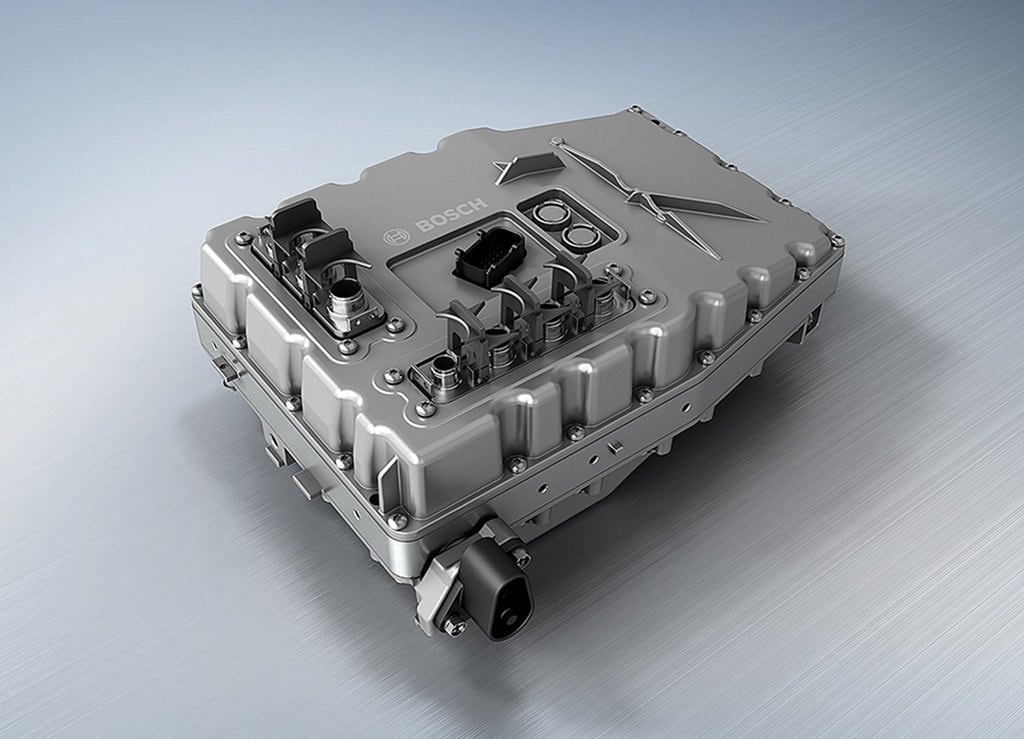

The power electronics offer an interface between the high voltage electric drive and the vehicle’s 12-volt electrical system. The system uses an inverter that converts the direct current from the battery into three-phase alternating current for the electric motor and vice versa.

One of the most difficult tasks for Bosch was to make the internal combustion engine and the IMG work together in a perfect interaction. Both units are controlled by the Motronic-based hybrid system control units. The control unit has continuous access to sensor data from the combustion engine, electric motor, battery, clutch and other components. It uses the gathered data to analyze and control the powertrains’ interaction in real time, making sure that the two units turn at the exact same speed when transferring the torque. This also ensures that the driving comfort is not affected by the switch between the electric unit’s motor and generator modes.

As for the direct-injection internal combustion engine, it is controlled by the Motronic unit down to the rate of individual injections. The control unit employs an additional CAN bus interface that allows the exchange of relevant data with the hybrid components, power electronics and battery.

The system also controls the braking process, with the hybrid control unit monitoring the pressure on the brake pedal to determine the brake torque that should be electrically set by the IMG. However, this process does not interfere with safety systems like ABS and ESP.

The seconds function is dubbed “power boost” and allows the combustion engine and the electric motor to work together. The system offers an overall output of 279 kW (380 hp) and a maximum torque of 580 Nm. This power and torque level matches that of the V8 petrol units installed on the first generations VW Touareg and Porsche Cayenne, but manages to cut fuel consumption and CO2 emissions by up to 40 percent.

In addition to that, future hybrids are set to eliminate some of the disadvantages of small capacity downsized turbocharged engines, such as poor low-end torque, allowing the downsizing concepts to become widespread.

The engine used by VW is a direct-injection supercharged 3.0 liter V6 petrol unit, which is matted to an eight-speed automatic transmission. The powerplant delivers 33 hp and a maximum torque of 440 Nm.

The electric motor used in the system is Bosch’s water-cooled Integrated Motor Generator (IMG), which comes with a separate clutch. The hybrid module is located between the internal combustion engine and the gearbox and requires a reduced amount of space, as it only has a diameter of 30 centimeters and a length of 145 mm.

The IMG develops 34 kW (46hp) and a maximum torque of 300 Nm, allowing the vehicle it is installed on to run at a speed of maximum 50 or 60 km/h (31 or 37 km/h) running exclusively on electric power. During the braking phase, the motor acts as a generator, recovering kinetic energy and converting it into electricity that is stored into the battery.

The system uses a nickel metal hybrid (NiMH) battery that has an energy capacity of 1.7 kWh, with a peak power of 288 volts.

The power electronics offer an interface between the high voltage electric drive and the vehicle’s 12-volt electrical system. The system uses an inverter that converts the direct current from the battery into three-phase alternating current for the electric motor and vice versa.

One of the most difficult tasks for Bosch was to make the internal combustion engine and the IMG work together in a perfect interaction. Both units are controlled by the Motronic-based hybrid system control units. The control unit has continuous access to sensor data from the combustion engine, electric motor, battery, clutch and other components. It uses the gathered data to analyze and control the powertrains’ interaction in real time, making sure that the two units turn at the exact same speed when transferring the torque. This also ensures that the driving comfort is not affected by the switch between the electric unit’s motor and generator modes.

As for the direct-injection internal combustion engine, it is controlled by the Motronic unit down to the rate of individual injections. The control unit employs an additional CAN bus interface that allows the exchange of relevant data with the hybrid components, power electronics and battery.

Special functions

The system offers two special functions, one for increasing efficiency and one for offering additional performance. The first is called “sailing mode": when the driver takes the foot off the throttle up to a speed of 100 mph (160 km/h), the combustion engine automatically shuts down, with the vehicle coasting with no fuel consumption. The system makes sure that this does not affect the driving safety and comfort.The system also controls the braking process, with the hybrid control unit monitoring the pressure on the brake pedal to determine the brake torque that should be electrically set by the IMG. However, this process does not interfere with safety systems like ABS and ESP.

The seconds function is dubbed “power boost” and allows the combustion engine and the electric motor to work together. The system offers an overall output of 279 kW (380 hp) and a maximum torque of 580 Nm. This power and torque level matches that of the V8 petrol units installed on the first generations VW Touareg and Porsche Cayenne, but manages to cut fuel consumption and CO2 emissions by up to 40 percent.

Applications data

The two SUVs, which weigh 2,938 lbs (2,240 kg), reach 62 mph (100 km/h) in 6.5 seconds, while returning a fuel consumption of 28.7 mpg (8.2 liters per 100 km) and emitting 193 grams of CO2 per km. Both vehicles comply with the Euro V and the U.S. ULEV 2 emissions standard.Future developments

Bosh is continuing to make efforts to develop the system (on a component level), in order to tackle issues such as reducing the size of the power electronics. This has the aim to enable broader application of the technology in different classes of cars. The developer has to maintain a balance between robust design, maximum efficiency and minimal space requirements. So far, the engineers have managed to reduce the volume of the power electronics by one third (to ten liters), without compromising the performance.In addition to that, future hybrids are set to eliminate some of the disadvantages of small capacity downsized turbocharged engines, such as poor low-end torque, allowing the downsizing concepts to become widespread.