Stop-start systems are becoming more popular nowadays, especially when taking into account that most governments across the world are offering incentives for green vehicles that achieve outstanding fuel efficiency and emission figures. Up until now, most carmaker out there developed their very own stop-start technology, obviously with a different name but all of them based on the same solution.

A stop-start system is especially aimed at shutting down the engine whenever the car is not in motion. For example, a car that spends a lot of time in traffic jams or at stop lights could very well reduce fuel consumption and cut emissions if the engine is automatically turned off when standing still. The engine is automatically restarted once the driver depresses the clutch looking for first gear or, in some cases, when he presses the throttle pedal. Obviously, the systems could be slightly different, depending on the manufacturers.

The lag between the moment the driver depresses the throttle pedal and the engine start is usually less than one second, which makes the whole process almost unnoticeable.

Just as we said, more and more carmakers are adopting this type of technologies but, due to a number of reasons – such as the increased costs for example, only 5 percent of the new vehicles sold around the world are equipped with such a system.

The system developed by PSA Peugeot Citroen for instance consists of a reversible alternator – that acts as both a starter and an alternator, a control unit and a battery that provides the necessary power. The stop-start controlling unit is connected to sensors in the braking system and controls the alternator; its role is to decide whether it is needed to activate the stop-start system or not. On the other hand, the alternator has been especially employed to reduce the time needed to start the engine and make the whole process as quick as possible.

Meanwhile, Controlled Power Technologies presented what they call “the second generation stop-start system”, a technology which is said to be much more efficient than the existing solutions and, more importantly, easier to implement in today's engines.

First of all, the manufacturer says the newly-developed system is based on a liquid cooled Switched Reluctance machine, which provides a simpler motor construction and very high power density and efficiency. The liquid cooling system plays a key role in the whole technology as it keeps both the motor windings and the electronics at the proper temperature levels, thus supporting maximum performance and efficiency. The temperature of the whole assembly should not exceed 105 Celsius degrees.

CPT's SpeedStart comes with all parts, including here the control and electronic components, into a single case, which allows it to be fitted on most engines currently on the market. The so-called Belt-driven Integrated Generator (B-ISG) can be installed on powertrains with gasoline engine displacements up to 3.0-liter and diesel units up to 2.5-liters.

To give you an idea on how efficient SpeedStart actually is, you should know that it can reduce both fuel consumption and CO2 emissions by 5 percent when integrated into a modern gasoline or diesel engines. Obviously, figures could vary by a number of factors, including driving style and engine configuration. Nevertheless, the manufacturer claims that SpeedStart provides the best figures in urban situations in which the stop-start system could demonstrate its efficiency and can reach in some cases a 20 percent improvement over a basic stop-start system.

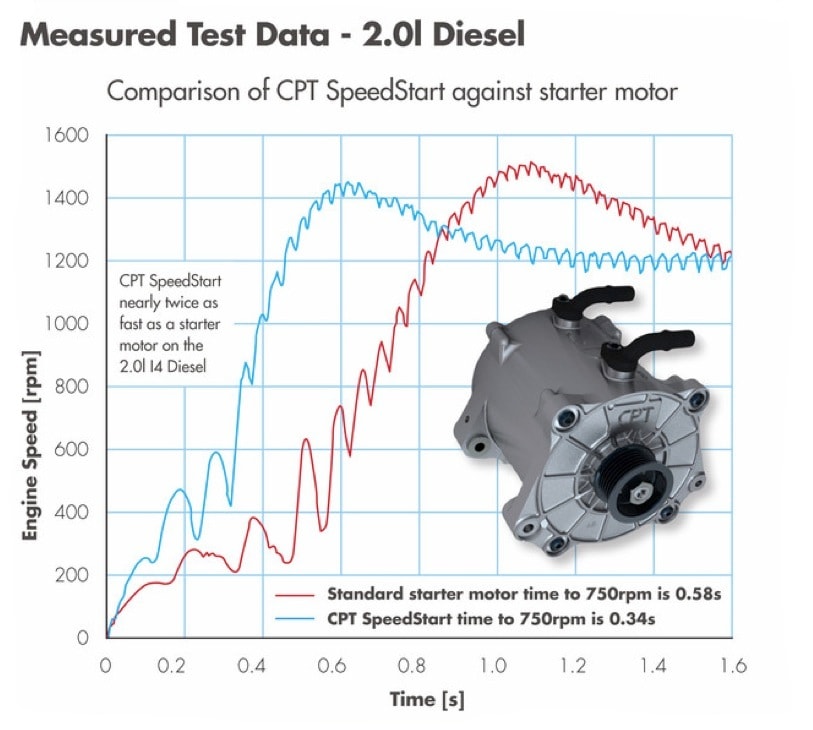

In order to demonstrate the abilities of the new system, CPT installed it on a Volvo S40 equipped with a 2.0-litre common rail diesel engine. According to official figures, the powerplant was restarted in almost half the time needed by a normal starter motor (0 to 750rpm in less than 0.4 seconds against typically 0.75 seconds).

A standard starter motor time would need 0.58 seconds to start the engine and bring it at 750 rpm while CPT's SpeedStart can do the same in 0.34 seconds. This means the system can further reduce lag caused by a stop-start function and, thanks to its high power, can handle a situation when the shut down is not needed anymore but the system has already started stopping the engine.

Here are a few specifications, as provided by the parent manufacturer:

A stop-start system is especially aimed at shutting down the engine whenever the car is not in motion. For example, a car that spends a lot of time in traffic jams or at stop lights could very well reduce fuel consumption and cut emissions if the engine is automatically turned off when standing still. The engine is automatically restarted once the driver depresses the clutch looking for first gear or, in some cases, when he presses the throttle pedal. Obviously, the systems could be slightly different, depending on the manufacturers.

The lag between the moment the driver depresses the throttle pedal and the engine start is usually less than one second, which makes the whole process almost unnoticeable.

Just as we said, more and more carmakers are adopting this type of technologies but, due to a number of reasons – such as the increased costs for example, only 5 percent of the new vehicles sold around the world are equipped with such a system.

The system developed by PSA Peugeot Citroen for instance consists of a reversible alternator – that acts as both a starter and an alternator, a control unit and a battery that provides the necessary power. The stop-start controlling unit is connected to sensors in the braking system and controls the alternator; its role is to decide whether it is needed to activate the stop-start system or not. On the other hand, the alternator has been especially employed to reduce the time needed to start the engine and make the whole process as quick as possible.

Meanwhile, Controlled Power Technologies presented what they call “the second generation stop-start system”, a technology which is said to be much more efficient than the existing solutions and, more importantly, easier to implement in today's engines.

First of all, the manufacturer says the newly-developed system is based on a liquid cooled Switched Reluctance machine, which provides a simpler motor construction and very high power density and efficiency. The liquid cooling system plays a key role in the whole technology as it keeps both the motor windings and the electronics at the proper temperature levels, thus supporting maximum performance and efficiency. The temperature of the whole assembly should not exceed 105 Celsius degrees.

CPT's SpeedStart comes with all parts, including here the control and electronic components, into a single case, which allows it to be fitted on most engines currently on the market. The so-called Belt-driven Integrated Generator (B-ISG) can be installed on powertrains with gasoline engine displacements up to 3.0-liter and diesel units up to 2.5-liters.

To give you an idea on how efficient SpeedStart actually is, you should know that it can reduce both fuel consumption and CO2 emissions by 5 percent when integrated into a modern gasoline or diesel engines. Obviously, figures could vary by a number of factors, including driving style and engine configuration. Nevertheless, the manufacturer claims that SpeedStart provides the best figures in urban situations in which the stop-start system could demonstrate its efficiency and can reach in some cases a 20 percent improvement over a basic stop-start system.

In order to demonstrate the abilities of the new system, CPT installed it on a Volvo S40 equipped with a 2.0-litre common rail diesel engine. According to official figures, the powerplant was restarted in almost half the time needed by a normal starter motor (0 to 750rpm in less than 0.4 seconds against typically 0.75 seconds).

A standard starter motor time would need 0.58 seconds to start the engine and bring it at 750 rpm while CPT's SpeedStart can do the same in 0.34 seconds. This means the system can further reduce lag caused by a stop-start function and, thanks to its high power, can handle a situation when the shut down is not needed anymore but the system has already started stopping the engine.

Here are a few specifications, as provided by the parent manufacturer:

- Start time to idle (750rpm) - <400ms

- Nominal cranking power - 2.4kW

- Machine stall torque (Cold) - 72 Nm @ -10°C

- Continuous generation power - 2.7kW

- Peak generation power - 3.0kW

- Low engine speed generation power - 2.0kW

- Typical generation efficiency - 75-85%

- Liquid cooled from engine circuit – 105 degrees C