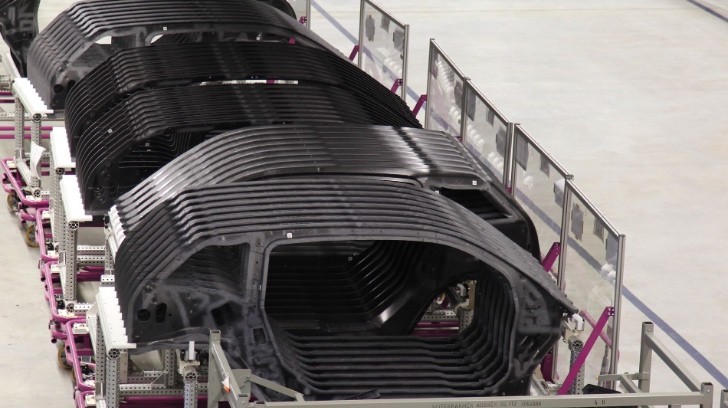

After investing €2 billion in the creation of the i sub-brand and the adjacent technologies and products needed for it, BMW is now looking to cash out on them as soon as possible. This includes Carbon Fiber Reinforced Polymer, a mix that is cheaper than pure carbon fiber to make and stronger at the same time.

It’s the material everyone heard about ever since the i3 and i8 models came out as they are basically made out of the thing. In order to make it without surging costs though, BMW joined with SGL Carbon, American company, and basically built a plant from the ground up near Moses Lake.

Why near the lake? Because they are using renewable energy to make CFRP so that it costs less and has a lower impact on the environment. However, that poses some challenges too.

The production is being maxed out now and can’t keep up with the demand. Furthermore, BMW is only using the material in the i3 and i8 and some bits and pieces for M cars like the propshaft of the M4 and the roof of the M6. That’s basically it and they still can’t handle it.

Now, imagine the material would be used on the 3 Series, their best selling car. They are basically selling hundreds of thousands of these things unlike the couple thousand the i cars account for today. How would they manage?

That’s exactly the excuse Adrian von Hooydonk used when asked about what he would like to do for the next models in line for BMW’s future plans.

Although he admitted to be a great fan of CFRP, he also said that BMW doesn’t have the facilities that would allow them to keep the production up to par without cutting corners. One of them would be to set up another plant that would use conventional energy but then the manufacturing would be more expensive, the impact on the environment bigger and so on...

So, what is the solution then? Well, van Hooydonk doesn’t know it but he’s adamant that given the opportunity, he could change the way the 3 Series is made.

On a related topic, he also pointed out that future Bimmers will keep their spartan interiors with clean, minimal lines throughout the cabin that will be easier to make due to the new tech that allows them to use touch-sensitive surfaces. Looks promising but here’s to hoping that an improvement in the quality of the materials used will also be included in the future plans.

Why near the lake? Because they are using renewable energy to make CFRP so that it costs less and has a lower impact on the environment. However, that poses some challenges too.

The production is being maxed out now and can’t keep up with the demand. Furthermore, BMW is only using the material in the i3 and i8 and some bits and pieces for M cars like the propshaft of the M4 and the roof of the M6. That’s basically it and they still can’t handle it.

Now, imagine the material would be used on the 3 Series, their best selling car. They are basically selling hundreds of thousands of these things unlike the couple thousand the i cars account for today. How would they manage?

That’s exactly the excuse Adrian von Hooydonk used when asked about what he would like to do for the next models in line for BMW’s future plans.

Although he admitted to be a great fan of CFRP, he also said that BMW doesn’t have the facilities that would allow them to keep the production up to par without cutting corners. One of them would be to set up another plant that would use conventional energy but then the manufacturing would be more expensive, the impact on the environment bigger and so on...

So, what is the solution then? Well, van Hooydonk doesn’t know it but he’s adamant that given the opportunity, he could change the way the 3 Series is made.

On a related topic, he also pointed out that future Bimmers will keep their spartan interiors with clean, minimal lines throughout the cabin that will be easier to make due to the new tech that allows them to use touch-sensitive surfaces. Looks promising but here’s to hoping that an improvement in the quality of the materials used will also be included in the future plans.