Around the world, the majority of the world still derives its energy from dirty, pollution-heavy, and toxic petrochemical-fired power stations. As the world at large scrambles like headless chickens to convert to something resembling a carbon-free global energy grid, Westinghouse Electric seems ready to lead the charge towards change. That's why their all-new AP300 small module reactor (SMR), might be the next big thing in commercial fission.

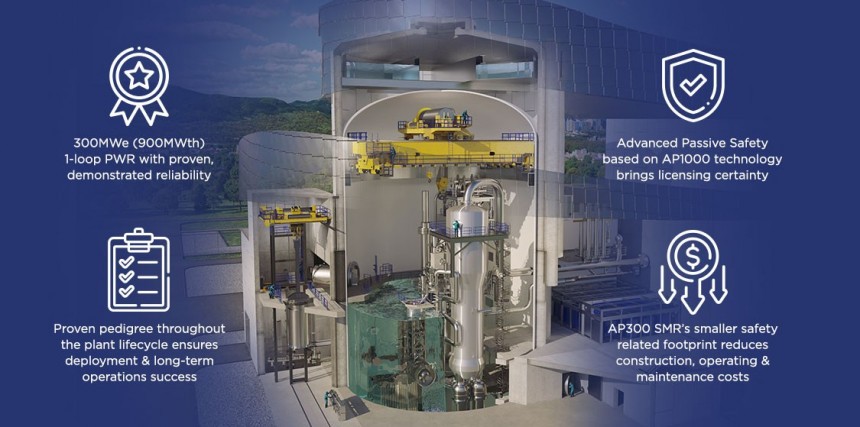

As a scaled-down and fully-modular interpretation of a third-generation pressurized water reactor (PWR), the AP300 design will operate on the same principles of nuclear reactors already in service. The novel mid-size reactor's public unveiling on May 4th, 2023, served as a simple yet profound statement to the rest of the energy sector. Fission reactors no longer need to be monstrous, costly, and publicly polarizing leviathans.

With a form factor that doesn't quite touch a micro-reactor while not being colossal either, the AP300 SMR's design has application potential across a broad spectrum that larger reactors can't accommodate. But to understand why some energy companies are so hot-set on building smaller modular reactor platforms, you need to look at affairs from a more holistic perspective. Indeed, larger nuclear reactors, with gigantic cooling towers and vast infrastructure, produce massive levels of thermal energy and, therefore, useable electricity.

But the real nagging issues with huge fission reactors often need to be connected to the reactors themselves. The constant threat of anti-nuclear activists hand-cuffing themselves to perimeter fences outside the construction site of a large reactor, as we've seen before in North America and Europe, often means more ambitious reactors, targeted at directly powering large cities, are seldom actually built. Inconsistent government funding often adds to this issue. But even the large reactors that make it off the drawing board require profound investments of manpower, construction time, personnel, and plain old money to get off the ground.

For all these reasons, Westinghouse's ambitions to take their AP1000 commercial pressurized-water reactor (PWR) and scale each component to more manufacturable proportions make logical sense. Fission reactor hardware small enough to be assembled in one location and then shipped to an on-site construction operation ultimately saves time, prevents staffing shortages with overall smaller and more expedient projects, and mitigates construction costs from not needing to build billions of dollars in on-site infrastructure larger reactors require.

At its heart, the AP300 SMR is as close to a one-to-one replica of the larger AP1000 already in service as is possible with modern manufacturing. In critical factors significant to making governments and private investors write checks, Westinghouse anticipates the knowledge gained from operating the AP1000 in China at the Sanmen Nuclear Power Station in Zhejiang will pay dividends in manufacturing the AP300 SMR more expediently.

The AP1000 itself is a marvelous machine in its own right. By pressurizing the water pumped through the nuclear pressure vessel's reactor core at temperatures far above its boiling point, this liquid is prevented from turning into superheated steam until it's pumped into an unpressurized steam chamber. Here, the drastic change in pressure forces a torrent of steam through a series of cooling loops before being fed through turbine halls where thermal energy is converted to electricity.

In all nuclear reactors using PWR technology, this basic operating principle is near-universal. But the AP1000 and the AP300 SMR, by extension, take the level of refinement, safety, and thermal energy output and brings it to some of the highest standards possible in the early 2020s. Needing only two cooling loops instead of the standard three to four and fewer safety valves, piping, and less building space, Westinghouse undoubtedly had an easier time scaling down the AP1000 to a modular design than had the same been attempted with other forms of PWR.

Of course, the AP300 SMR is bound to be even simpler than its big brother by virtue of its smaller size. With only a single cooling loop needed, the reactor is slated to generate a healthy 900 MW of thermal energy and 300 MW of usable electricity. In comparison to the 1,117 MWe generated by the larger AP1000, it's clear the degree of scalability between itself and the AP300 was considerable. When arranged at strategic points in a large city's energy grid, it might even be possible for cities dependent on small coal-fired power plants to ditch them entirely by replacing them with a fleet of AP300 SMRs.

Of course, a small fleet of mini-reactors around the circumference of a major city might make it hard for some to sleep at night. But don't fear; Westinghouse has these people in mind. In many ways, Westinghouse AP-class reactors are the antithesis of the RBMKs responsible for Chornobyl (Chernobyl). With its ability to passively mitigate anomalies within its reactor and initiate a safe shutdown without operator input, Westinghouse engineers can troubleshoot problems remotely, without any personnel remaining on site, for up to 72 hours.

Westinghouse even designed the AP1000 to be remote-shutdown-capable in the event of a complete blackout with a 100 percent loss of AC power. In short, it's almost impossible for operator error to bring an AP-class reactor to a state of dangerous super-criticality, as happened in Ukraine in 1986. Save for an unpredicted software glitch; there's no reason a fleet of AP300 SMRs can't operate flawlessly for decades at a time. The average commercial fission reactor operates for between 20 to 40 years, according to the International Atomic Energy Agency.

Westinghouse aims to double this figure, roughly 70 to 80 years, across both the AP 1000 and AP300. It's rare for a coal-fired power station to last anywhere near that long. For now, Westinghouse anticipates a certification for its new medium-sized nuclear reactor in the U.S., Great Britain, and China by 2027 at the earliest. Soon after, the company will begin fielding offers from government and privately-run investment groups to fund the construction of the first operational AP300 reactor sometime just before or just after the 2020s are out.

With the AP1000, AP300, and also the eVinci microreactor, the Westinghouse Electric team of Cranberry Township, Pennsylvania, has managed to run the whole gamut in the nuclear sector from pint-sized to the giant. Large fleets of small nuclear reactors powering global cities might make those who've watched too many movies about nuclear meltdowns a little queasy. As global demands for clean energy skyrocket across the globe, the time will soon come when people won't be so picky about where their energy comes from.

When this day comes, the Westinghouse AP-class nuclear reactor seems well suited to meet demands. With more electric cars now on the road than ever before, all those EVs need to charge up somehow.

With a form factor that doesn't quite touch a micro-reactor while not being colossal either, the AP300 SMR's design has application potential across a broad spectrum that larger reactors can't accommodate. But to understand why some energy companies are so hot-set on building smaller modular reactor platforms, you need to look at affairs from a more holistic perspective. Indeed, larger nuclear reactors, with gigantic cooling towers and vast infrastructure, produce massive levels of thermal energy and, therefore, useable electricity.

But the real nagging issues with huge fission reactors often need to be connected to the reactors themselves. The constant threat of anti-nuclear activists hand-cuffing themselves to perimeter fences outside the construction site of a large reactor, as we've seen before in North America and Europe, often means more ambitious reactors, targeted at directly powering large cities, are seldom actually built. Inconsistent government funding often adds to this issue. But even the large reactors that make it off the drawing board require profound investments of manpower, construction time, personnel, and plain old money to get off the ground.

For all these reasons, Westinghouse's ambitions to take their AP1000 commercial pressurized-water reactor (PWR) and scale each component to more manufacturable proportions make logical sense. Fission reactor hardware small enough to be assembled in one location and then shipped to an on-site construction operation ultimately saves time, prevents staffing shortages with overall smaller and more expedient projects, and mitigates construction costs from not needing to build billions of dollars in on-site infrastructure larger reactors require.

The AP1000 itself is a marvelous machine in its own right. By pressurizing the water pumped through the nuclear pressure vessel's reactor core at temperatures far above its boiling point, this liquid is prevented from turning into superheated steam until it's pumped into an unpressurized steam chamber. Here, the drastic change in pressure forces a torrent of steam through a series of cooling loops before being fed through turbine halls where thermal energy is converted to electricity.

In all nuclear reactors using PWR technology, this basic operating principle is near-universal. But the AP1000 and the AP300 SMR, by extension, take the level of refinement, safety, and thermal energy output and brings it to some of the highest standards possible in the early 2020s. Needing only two cooling loops instead of the standard three to four and fewer safety valves, piping, and less building space, Westinghouse undoubtedly had an easier time scaling down the AP1000 to a modular design than had the same been attempted with other forms of PWR.

Of course, the AP300 SMR is bound to be even simpler than its big brother by virtue of its smaller size. With only a single cooling loop needed, the reactor is slated to generate a healthy 900 MW of thermal energy and 300 MW of usable electricity. In comparison to the 1,117 MWe generated by the larger AP1000, it's clear the degree of scalability between itself and the AP300 was considerable. When arranged at strategic points in a large city's energy grid, it might even be possible for cities dependent on small coal-fired power plants to ditch them entirely by replacing them with a fleet of AP300 SMRs.

Westinghouse even designed the AP1000 to be remote-shutdown-capable in the event of a complete blackout with a 100 percent loss of AC power. In short, it's almost impossible for operator error to bring an AP-class reactor to a state of dangerous super-criticality, as happened in Ukraine in 1986. Save for an unpredicted software glitch; there's no reason a fleet of AP300 SMRs can't operate flawlessly for decades at a time. The average commercial fission reactor operates for between 20 to 40 years, according to the International Atomic Energy Agency.

Westinghouse aims to double this figure, roughly 70 to 80 years, across both the AP 1000 and AP300. It's rare for a coal-fired power station to last anywhere near that long. For now, Westinghouse anticipates a certification for its new medium-sized nuclear reactor in the U.S., Great Britain, and China by 2027 at the earliest. Soon after, the company will begin fielding offers from government and privately-run investment groups to fund the construction of the first operational AP300 reactor sometime just before or just after the 2020s are out.

With the AP1000, AP300, and also the eVinci microreactor, the Westinghouse Electric team of Cranberry Township, Pennsylvania, has managed to run the whole gamut in the nuclear sector from pint-sized to the giant. Large fleets of small nuclear reactors powering global cities might make those who've watched too many movies about nuclear meltdowns a little queasy. As global demands for clean energy skyrocket across the globe, the time will soon come when people won't be so picky about where their energy comes from.