Thomas Schmall, Volkswagen's board member for technology, was the man in charge of explaining the unified cell at the Volkswagen Power Day. At the Volkswagen New Auto strategy presentation, he reinforced how crucial the concept will be for the German automaker in its quest to promote electromobility. Whatever the chemistry they might present, their job is to reduce costs through a massive scale.

Schmall mentioned that they can slash them by up to 50%. If that is correct, electric cars may soon go beyond production cost parity with ICE vehicles: they may become cheaper to produce, depending on the chemistry. That is why Volkswagen is working with four of them starting in 2023.

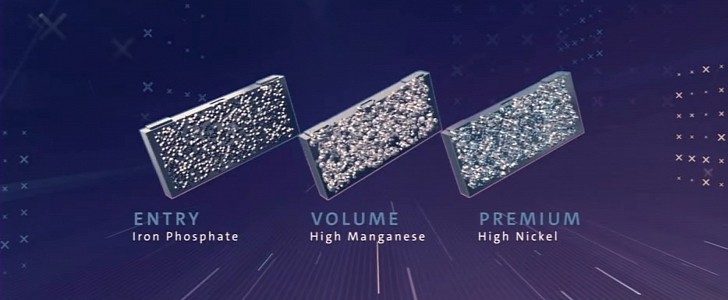

For entry-level vehicles, Volkswagen will adopt LFP (lithium iron phosphate) cells. They are already in use by Tesla in the Model 3 made in China and by Wuling in the Hongguang Mini EV. Apart from cost, these cells are also safer, with much lower risks of thermal runaway episodes.

For high-volume cars, unified cells will have high manganese cells, something battery specialists were not very convinced about. So far, they have presented a low cycle life and relatively low energy density. It seems Volkswagen managed to overcome those issues with its suppliers, such as Gotian. According to Frank Blome – Volkswagen Group Component's head of battery cell and system – manganese is much cheaper than nickel, which offers higher energy density.

Unified cells will also use high-nickel cells for premium applications, but the most awaited chemistry for that prismatic solution will be solid-state batteries. Schmall confirmed it is compatible with the new technology and reinforced that QuantumScape cells were already tested by Volkswagen. The German carmaker is so excited about the tech that it wants the first pilot plant for these cells to be in Germany.

Apart from being so versatile when it comes to chemistries, Schmall said the unified cells would also be compatible with crucial new technologies for batteries: cell-to-pack (which makes the own cells form the battery pack, with no need for a case), cell-to-car (a structural battery pack), dry coating, and high-silicon anodes.

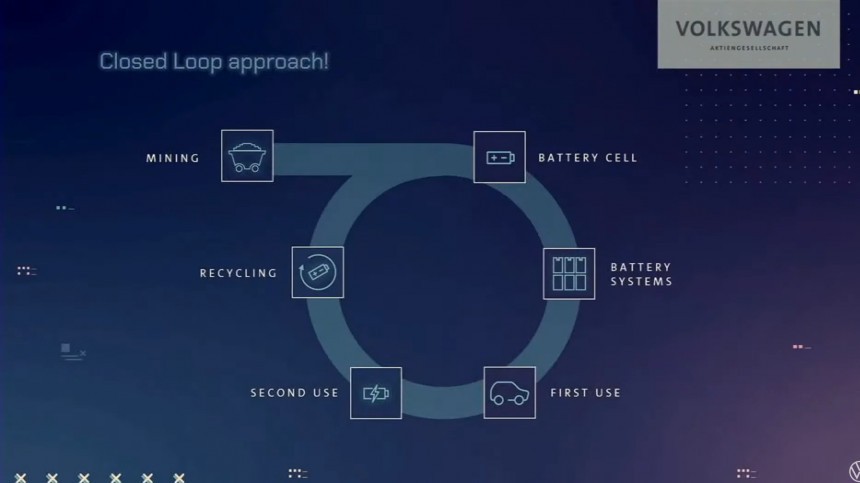

To support that strategy, Volkswagen wants to adopt what it calls a “closed-loop approach.” It will consist of making batteries, using them in electric cars, getting them to work a little more with stationary energy storage, recycle them, and start this cycle all over again.

Unfortunately, it is not clear if Volkswagen will get directly involved with mining or if it will only make strategic partnerships with mining companies to ensure access to raw materials. According to the carmaker, mining and creating the right chemistry correspond to 80% of the cell value.

That’s a radical shift from when turning iron or aluminum into engines was the name of the game. Batteries are the core of electric vehicles and Volkswagen cannot leave them solely with suppliers. The recent lesson with semiconductors shows that the automotive industry will have to worry about more aspects of production than it used to care for.

According to Schmall, Volkswagen will establish strategic partnerships and expand their scope to find the right balance between making or buying cells. That’s what leads us to believe that even mining is on the table for the German automaker. Chinese battery recycling companies have already complained that they do not have enough battery packs to work with, which means mining will be an essential part of making cells for many years to come.

Of the six 40-GWh battery factories Volkswagen plans to establish, three have already been defined and all of them are in Europe so far. The first is in Sweden, with Northvolt, and Volkswagen is investing €500 million more there.

The second one is in Salzgitter, Germany, and we had the impression it was fully owned by Volkswagen. That’s only the case if you consider that the German car company owns a large share of Gotian, a Chinese battery company. Volkswagen will have Gotian produce its unified cells in the German plant.

The latest cell factory to be established will be in Spain, which won a dispute with Portugal to receive the more than €4 billion investment thanks to PERTE (Proyecto Estratégico para la Recuperación y Transformación Económica, or Strategic Project for Economic Recovery and Transformation).

For entry-level vehicles, Volkswagen will adopt LFP (lithium iron phosphate) cells. They are already in use by Tesla in the Model 3 made in China and by Wuling in the Hongguang Mini EV. Apart from cost, these cells are also safer, with much lower risks of thermal runaway episodes.

For high-volume cars, unified cells will have high manganese cells, something battery specialists were not very convinced about. So far, they have presented a low cycle life and relatively low energy density. It seems Volkswagen managed to overcome those issues with its suppliers, such as Gotian. According to Frank Blome – Volkswagen Group Component's head of battery cell and system – manganese is much cheaper than nickel, which offers higher energy density.

Apart from being so versatile when it comes to chemistries, Schmall said the unified cells would also be compatible with crucial new technologies for batteries: cell-to-pack (which makes the own cells form the battery pack, with no need for a case), cell-to-car (a structural battery pack), dry coating, and high-silicon anodes.

To support that strategy, Volkswagen wants to adopt what it calls a “closed-loop approach.” It will consist of making batteries, using them in electric cars, getting them to work a little more with stationary energy storage, recycle them, and start this cycle all over again.

That’s a radical shift from when turning iron or aluminum into engines was the name of the game. Batteries are the core of electric vehicles and Volkswagen cannot leave them solely with suppliers. The recent lesson with semiconductors shows that the automotive industry will have to worry about more aspects of production than it used to care for.

According to Schmall, Volkswagen will establish strategic partnerships and expand their scope to find the right balance between making or buying cells. That’s what leads us to believe that even mining is on the table for the German automaker. Chinese battery recycling companies have already complained that they do not have enough battery packs to work with, which means mining will be an essential part of making cells for many years to come.

The second one is in Salzgitter, Germany, and we had the impression it was fully owned by Volkswagen. That’s only the case if you consider that the German car company owns a large share of Gotian, a Chinese battery company. Volkswagen will have Gotian produce its unified cells in the German plant.

The latest cell factory to be established will be in Spain, which won a dispute with Portugal to receive the more than €4 billion investment thanks to PERTE (Proyecto Estratégico para la Recuperación y Transformación Económica, or Strategic Project for Economic Recovery and Transformation).