Around 40 years’ worth of mineable copper resources remain worldwide at the moment and global consumption for this highly conductive metal is growing pretty fast along with vehicle production and other needs in infrastructure for emerging markets.

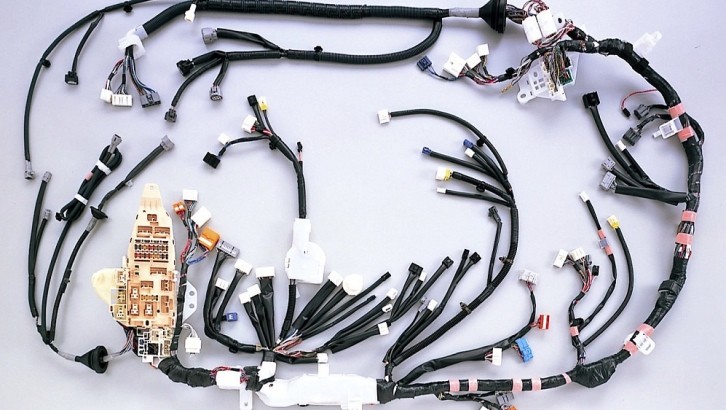

In the automotive industry, copper is used for the necessary wiring harnesses between the vehicles’ electronic parts and with the hybrids’ rapid expansion, more and more copper is needed for the green vehicles’ electric motors and other connecting wires.

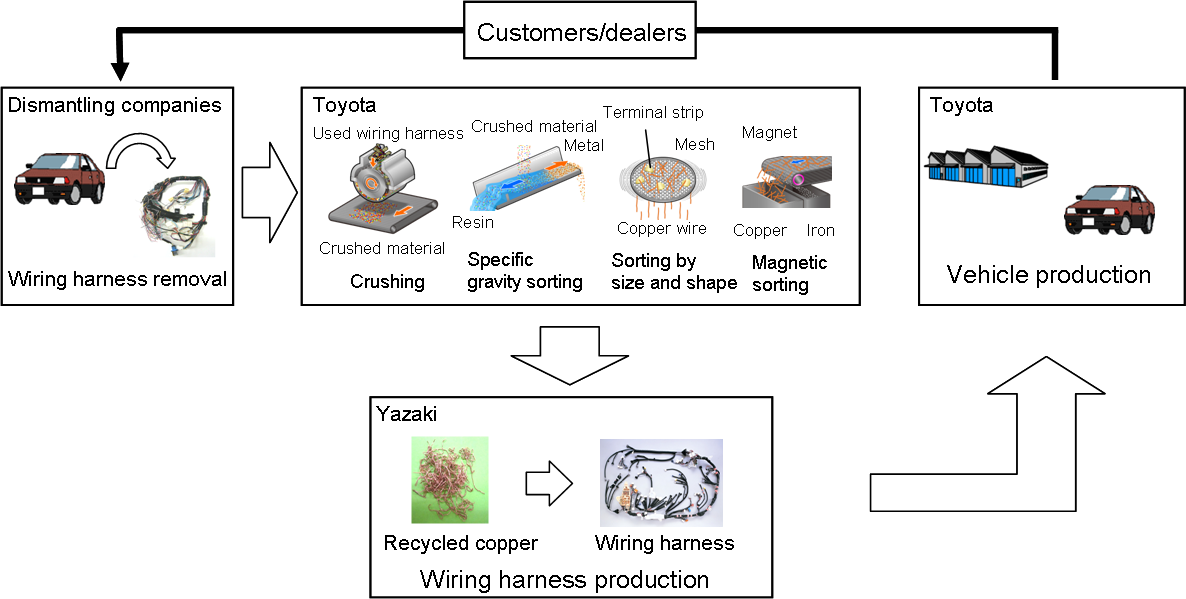

Being the biggest hybrid vehicles supplier, Toyota is aware of this and has developed a world-first technology for recycling the copper contained in wiring harnesses. In collaboration with Yazaki Corporation, Toyota Tsusho Corporation and 8 other companies, the new technology provides recycled copper with a purity of 99.96 percent.

When wiring harnesses are conventionally removed from end-to-life vehicles it’s extremely difficult to separate the copper from the fuse box and other components. As a result, it has not been possible to recycle copper from vehicles until now.

In 2011, TMC developed the first mechanical sorting method that can prevent contamination from minute impurities. Trial production involving small amounts of recycled copper began at TMC’s Honsha Plant in 2013. Once quality had been assessed by Yazaki, the copper was introduced to the wiring harness manufacturing line. Stable production involving recycled copper has been achieved, and annual production of recycled copper using this method will increase to approximately 1,000 tons in 2016.

Being the biggest hybrid vehicles supplier, Toyota is aware of this and has developed a world-first technology for recycling the copper contained in wiring harnesses. In collaboration with Yazaki Corporation, Toyota Tsusho Corporation and 8 other companies, the new technology provides recycled copper with a purity of 99.96 percent.

When wiring harnesses are conventionally removed from end-to-life vehicles it’s extremely difficult to separate the copper from the fuse box and other components. As a result, it has not been possible to recycle copper from vehicles until now.

In 2011, TMC developed the first mechanical sorting method that can prevent contamination from minute impurities. Trial production involving small amounts of recycled copper began at TMC’s Honsha Plant in 2013. Once quality had been assessed by Yazaki, the copper was introduced to the wiring harness manufacturing line. Stable production involving recycled copper has been achieved, and annual production of recycled copper using this method will increase to approximately 1,000 tons in 2016.