Engineers from Lawrence Livermore National Laboratory (LLNL) have proposed reshaping heavy vehicles such as semi-trucks to be more aerodynamic. This new continuous design could significantly reduce drag, increase fuel efficiency, and cut carbon emissions.

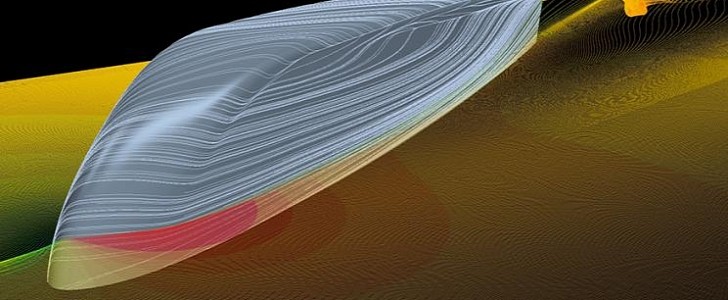

In a recent study published in the National Academy of Sciences, researchers from LLNL have worked to demonstrate that aerodynamic vehicle designs are reducing drag by creating negative front pressures. This pressure pulls the vehicle forward against the wind just like a sailboat.

Aerodynamic drag reduction plays a significant role in meeting fuel consumption goals. A more streamlined vehicle will be able to reach higher speeds and, as a result, will also have increased fuel efficiency. In the U.S., heavy duty vehicles make up just 4 percent of all on-road vehicles, but they account for more than 20 percent of all transportation-related greenhouse emissions.

The comparatively high drag coefficient of heavy vehicles, which may vary from 0.8 to 1.0, compared to 0.3 for a sedan and 0.4 for an SUV, is one of the major causes of inefficiency leading to their poor fuel economy. It has been found that aerodynamic drag can be affected by using various add-on devices. Some of them include boat tail plates, trailer skirts, tractor side, and roof extenders.

While they have some advantages in terms of reducing drag, a solution proposed by the LLNL team of researchers is targeting the vehicle's overall shape. Based on wind tunnel tests and computational simulations, they determined that a new design, which resembles a bullet train, would generate drag values that are considerably lower than those of current heavy vehicles.

This bullet train model could have a significant impact on the heavy truck freight sector, which, according to the LLNL, it made use of over 30 billion gallons of diesel in 2017. For a heavy vehicle traveling at highway speeds, a 1 percent reduction in drag results in a 0.45 percent reduction in fuel consumption.

Aerodynamic drag reduction plays a significant role in meeting fuel consumption goals. A more streamlined vehicle will be able to reach higher speeds and, as a result, will also have increased fuel efficiency. In the U.S., heavy duty vehicles make up just 4 percent of all on-road vehicles, but they account for more than 20 percent of all transportation-related greenhouse emissions.

The comparatively high drag coefficient of heavy vehicles, which may vary from 0.8 to 1.0, compared to 0.3 for a sedan and 0.4 for an SUV, is one of the major causes of inefficiency leading to their poor fuel economy. It has been found that aerodynamic drag can be affected by using various add-on devices. Some of them include boat tail plates, trailer skirts, tractor side, and roof extenders.

While they have some advantages in terms of reducing drag, a solution proposed by the LLNL team of researchers is targeting the vehicle's overall shape. Based on wind tunnel tests and computational simulations, they determined that a new design, which resembles a bullet train, would generate drag values that are considerably lower than those of current heavy vehicles.

This bullet train model could have a significant impact on the heavy truck freight sector, which, according to the LLNL, it made use of over 30 billion gallons of diesel in 2017. For a heavy vehicle traveling at highway speeds, a 1 percent reduction in drag results in a 0.45 percent reduction in fuel consumption.